Method and device for purifying cooking fume

A technology for oil fume purification and treatment method, which is applied in the direction of oil fume removal, heating method, and household heating, etc., can solve the problems of increasing environmental pollution, affecting residents' health, and poor kitchen fume treatment effect, and achieving the effect of solving pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

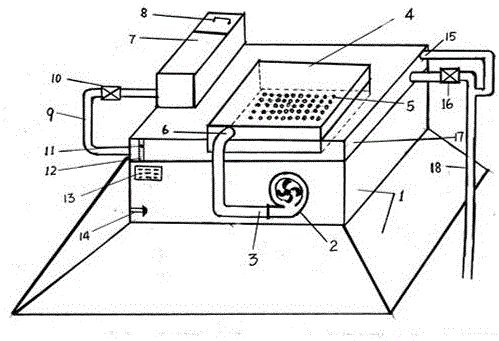

[0043] Refer to attached figure 1As shown, a kitchen fume purification treatment device of the present invention has a fume collection hood 1, and at least one vortex air pump fan 2 is arranged in the fume collection hood 1. The tuyere is connected with the air inlet 6 of the air storage box 4, the bottom of the air storage box 4 has a circular air guide hole 5, the upper part of the oil collection fume hood 1 is provided with a degreasing and deodorizing storage box 7, and the degreasing and deodorizing storage box 7 is provided with a feeding Cover 8, medicament pipeline 9 is equipped with medicament valve 10, medicament pipeline 9 is connected with storage tank 7 and oil fume reaction box 17, and oil fume reaction box 17 is equipped with liquid level sensor 11 and water level gauge 12, and the top of oil fume reaction box 17 is equipped with overflow Flow exhaust pipe 15, the bottom of oil fume reaction box 17 is equipped with blowdown pipe 18 with blowdown valve 16, and th...

Embodiment 2

[0058] Test item: Kitchen fume purification treatment device to remove kitchen fume (particulate matter)

[0059] The specific implementation of the detection method is based on GB / T18801-2008 "Air Purifier"

[0060] The laboratory is carried out in an airtight 30m³ experimental cabin, the present invention is placed in the center of the experimental cabin, the height is 1.8 meters, and adjusted to the working state, the inspection is normal, and then the overflow exhaust pipe 15 is connected to the outside of the experimental cabin with the collection device connected, and then turn off the device.

[0061] Pour the cooking oil into an iron pan and heat it on the induction cooker. The temperature of the induction cooker is set at 200°C.

[0062] Wait until the cooking oil starts to evaporate.

[0063] 1. Start the temperature and humidity control device, the temperature of the experimental cabin is (25±2) ℃, and the humidity is (50±10)%.

[0064] 2. Send the edible oil tha...

Embodiment 3

[0070] Test item: Kitchen oil fume purification treatment device to remove kitchen TVOC (total volatile organic compounds)

[0071] Testing basis: GB / T18801-2008 "Air Purifier"

[0072] GB / T18883-2002 "Indoor Air Quality Standard"

[0073] 1. The laboratory is carried out in a closed 30m³ experimental cabin. The invention is placed in the center of the experimental cabin, and adjusted to the working state, and the operation is checked to be normal, and then the device is closed.

[0074] 2. Arrange the location of the sampling point, avoid the air inlet and outlet, about 1 meter away from the wall, and 1.2 meters above the ground of the experimental cabin.

[0075] 3. Start the temperature and humidity control device, the temperature of the experimental cabin reaches (25±2)°C, and the relative humidity is (50±10)%.

[0076] 4. Release the configured TVOC (volatile organic compounds) into the experimental cabin, so that the TVOC concentration reaches about 6.0㎎ / m³, turn on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com