Copper and aluminium composite variable diameter metal heat pipe

A copper-aluminum composite, metal heat pipe technology, applied in indirect heat exchangers, lighting and heating equipment, etc., to achieve the effects of thermal performance improvement, cost reduction, market promotion prospects and increased acceptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

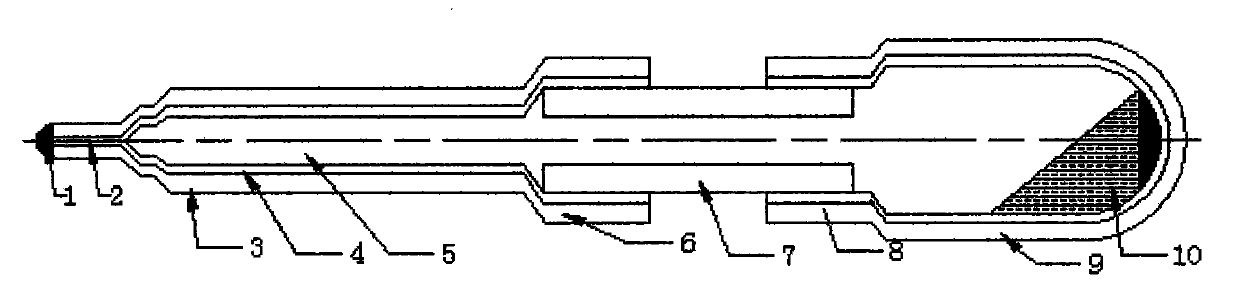

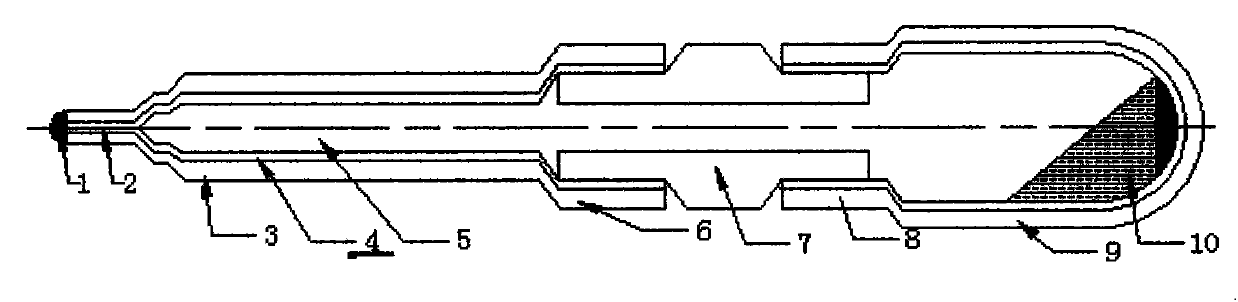

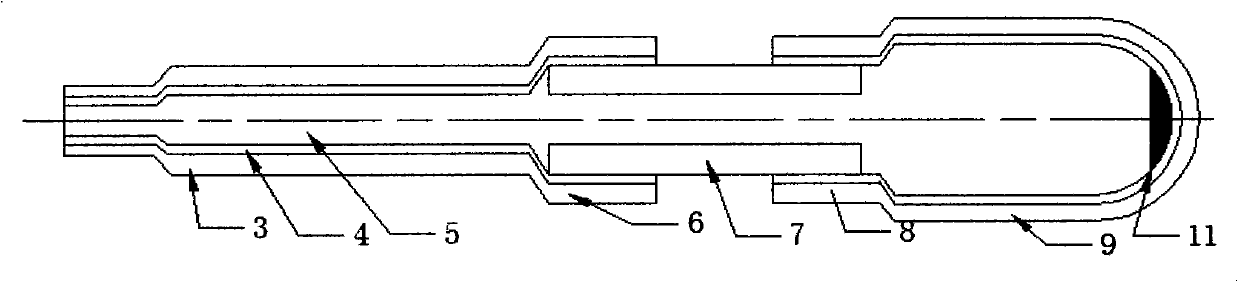

[0041] Such as figure 1 As shown, the copper-aluminum composite variable-diameter metal heat pipe of the present invention has three parts in its structure: a heat-absorbing section, a docking section, and a condensation section. External aluminum and internal copper structure, that is, aluminum-clad copper structure, the inner surface of the shell is made of red copper or oxygen-free copper, the wall thickness is 0.1-0.3mm, the outer surface of red copper or oxygen-free copper is compounded with pure aluminum or alloy aluminum, the thickness is average The total thickness of the shell is generally 0.5-1.2mm, and the diameter of the shell is generally 4mm-20mm.

[0042] The length of the copper-aluminum composite variable diameter metal heat pipe is generally 400mm-2500mm.

[0043] The heat absorbing section is composed of sealing solder joint 1, cold welding sealing section 2, heat absorbing section outer layer 3, heat absorbing section inner layer 4, heat absorbing section ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com