Greenhouse ventilation control device and control system thereof

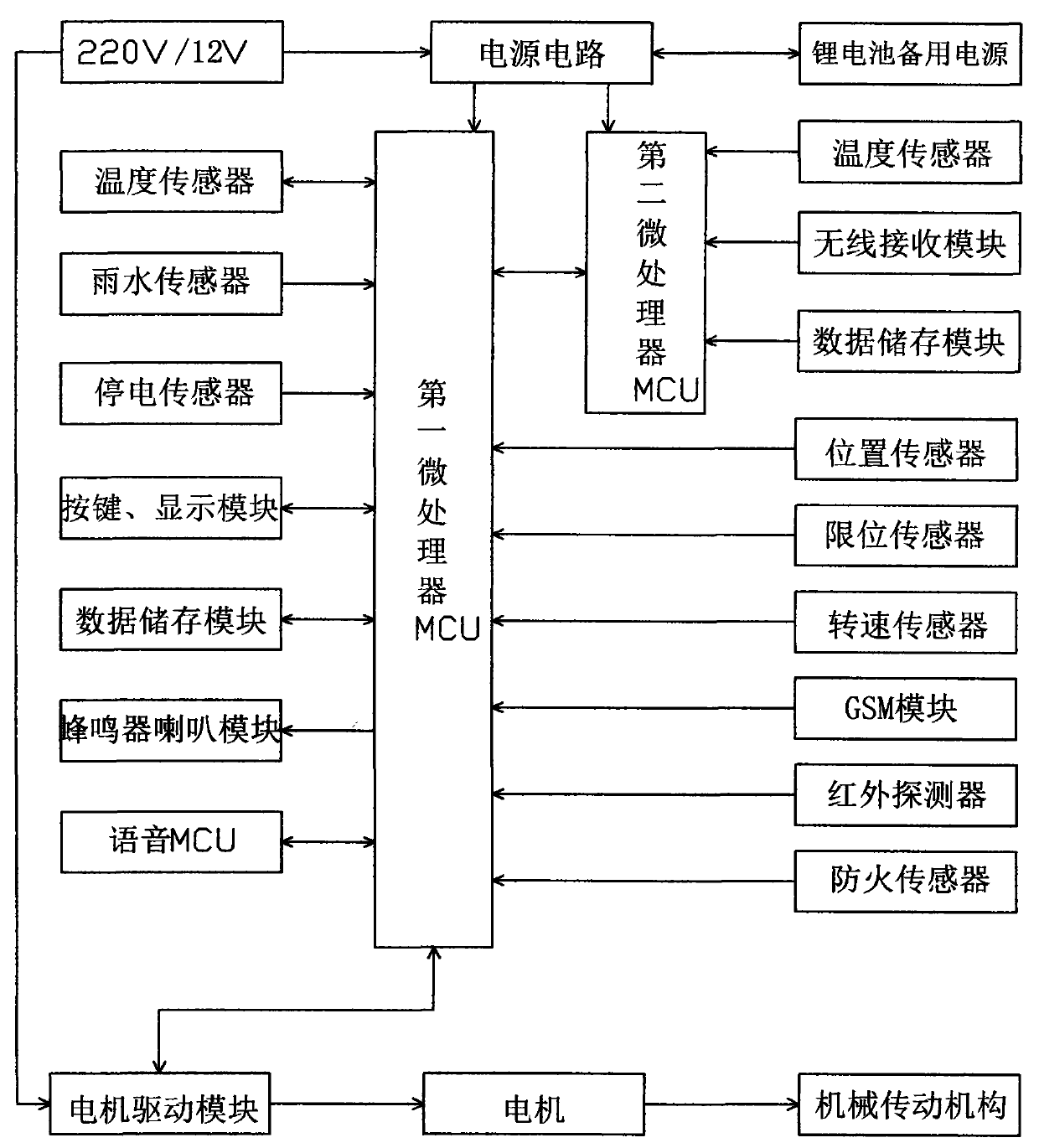

A control device and control system technology, applied in the direction of control/regulation system, comprehensive factory control, electrical program control, etc., can solve problems such as difficult operation, single function, large temperature change, etc., to overcome SMS notification and good safety , the effect of force balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

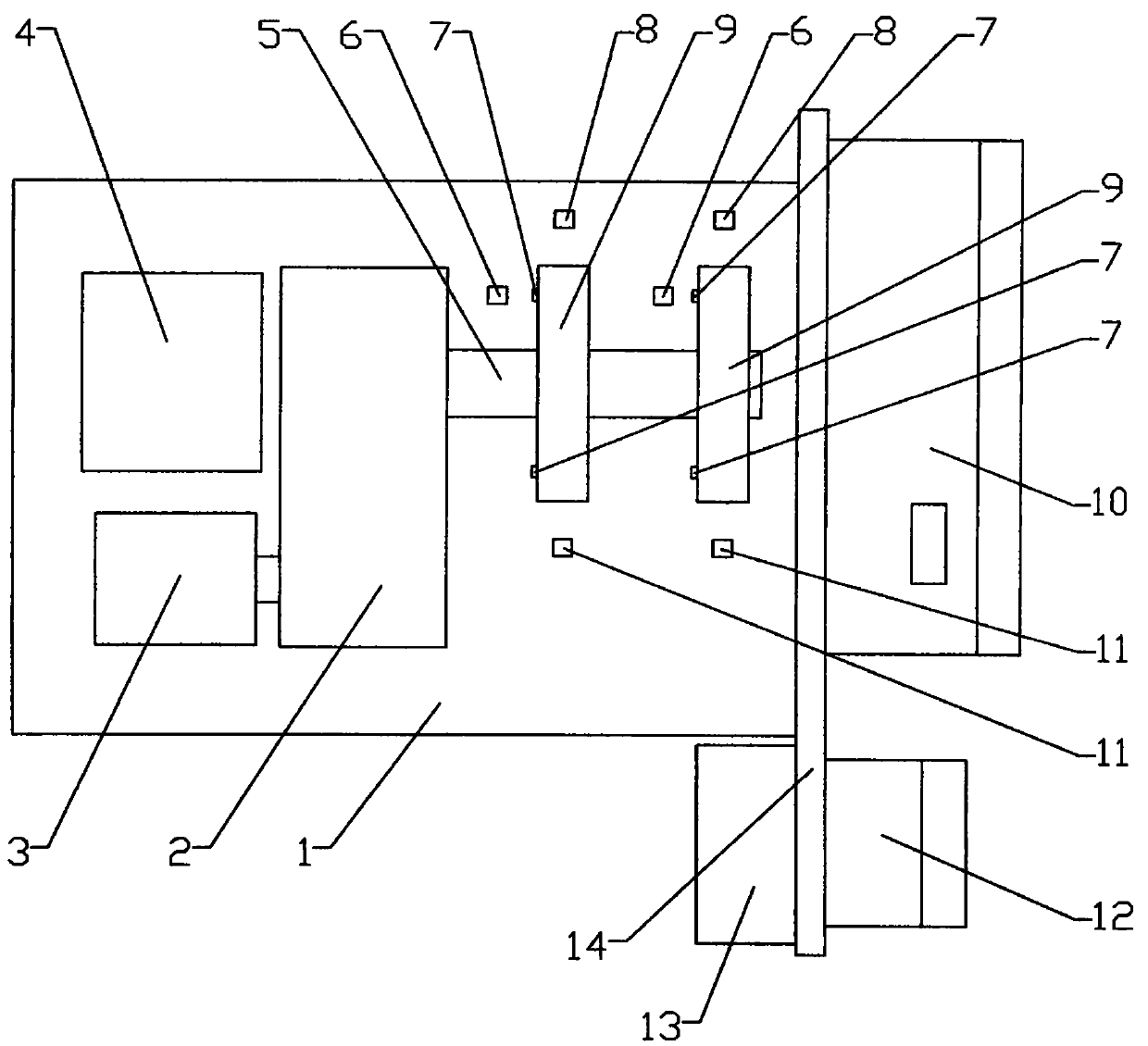

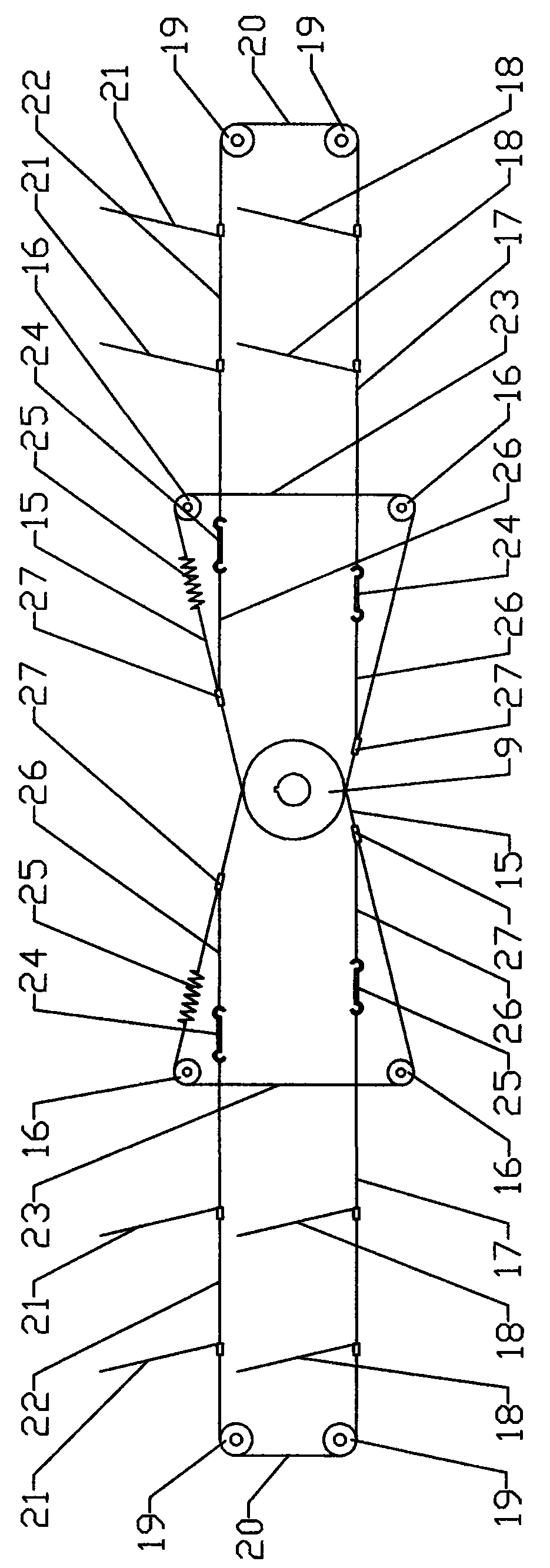

[0051]Embodiment 1: as attached figure 1 And attached figure 2 As shown, a greenhouse ventilation control device includes a base plate 1 and a baffle plate 14, a transmission 2, a motor 3 and a transformer 4 are arranged on the base plate 1 on one side of the baffle plate 14, and a controller 10 is provided on the other side of the baffle plate 14. and the SIM card box 12, the baffle plate 14 is provided with a power switch 13, the speed changer 2 is connected with the motor 3, and the output shaft 5 of the speed changer 2 is provided with two transmission wheels 9, and the transmission wheel 9 is provided with a transmission member matched with it 15. Two transmission members 15 are located on both sides of the output shaft 5.

[0052] The controller 10 is electrically connected to the transformer 4 and the motor 3 respectively, the transformer 4 is electrically connected to the motor 3 , and the SIM card box 12 is electrically connected to the controller 10 .

[0053] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com