High-strength control cable

A control cable, high-strength technology, applied in the direction of insulated cables, cables, circuits, etc., can solve problems such as potential safety hazards, shortened cable life, damage, etc., to achieve the effects of prolonging service life, improving strength, and reducing mechanical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

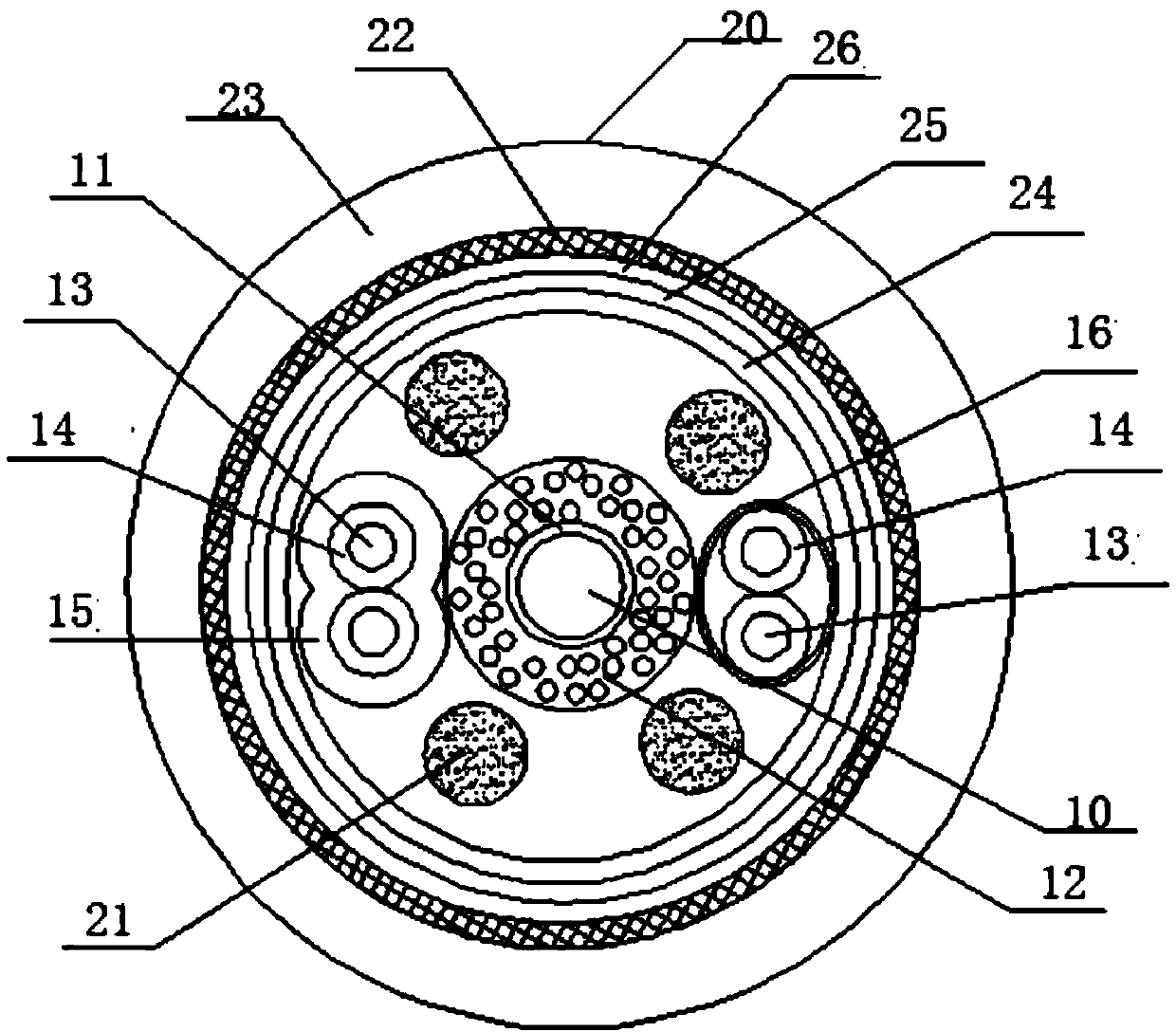

[0025] The high-strength control cable of the present invention consists of a first core 10, a conductive layer 11 arranged on the outer surface of the first core 10, and a first insulating layer 12 wrapped outside the conductive layer 11 to form an intermediate core; the outside of the intermediate core An isolation layer 22 is provided, and a left core composed of two second cores 13 intertwined with each other is provided between the middle core and the isolation layer 22, and a core isolation layer 14 is respectively provided on the outer surfaces of the two second cores 13 , the outer surface of the two intertwined second cores 13 is provided with a first insulating layer 15, wherein the two intertwined second cores 13 wrapped by the first insulating layer 15 form an "8" structure; the left core's " The 8" structure can strengthen the magnetic field strength between each other and effectively increase the transmission efficiency. A right wire core composed of two second w...

Embodiment 2

[0031] The high-strength control cable of the present invention consists of a first core 10, a conductive layer 11 arranged on the outer surface of the first core 10, and a first insulating layer 12 wrapped outside the conductive layer 11 to form an intermediate core; the outside of the intermediate core An isolation layer 22 is provided, and a left core composed of two second cores 13 intertwined with each other is provided between the middle core and the isolation layer 22, and a core isolation layer 14 is respectively provided on the outer surfaces of the two second cores 13 , the outer surface of the two intertwined second cores 13 is provided with a first insulating layer 15, wherein the two intertwined second cores 13 wrapped by the first insulating layer 15 form an "8" structure; the left core's " The 8" structure can strengthen the magnetic field strength between each other and effectively increase the transmission efficiency. A right wire core composed of two second w...

Embodiment 3

[0037] The high-strength control cable of the present invention consists of a first core 10, a conductive layer 11 arranged on the outer surface of the first core 10, and a first insulating layer 12 wrapped outside the conductive layer 11 to form an intermediate core; the outside of the intermediate core An isolation layer 22 is provided, and a left core composed of two second cores 13 intertwined with each other is provided between the middle core and the isolation layer 22, and a core isolation layer 14 is respectively provided on the outer surfaces of the two second cores 13 , the outer surface of the two intertwined second cores 13 is provided with a first insulating layer 15, wherein the two intertwined second cores 13 wrapped by the first insulating layer 15 form an "8" structure; the left core's " The 8" structure can strengthen the magnetic field strength between each other and effectively increase the transmission efficiency. A right wire core composed of two second w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com