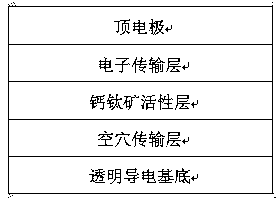

Preparation method for perovskite type solar cell based on spraying technology

A solar cell and perovskite-type technology, applied in the field of solar cells, can solve the problems that limit the industrialization of perovskite solar cells and cannot be applied to the preparation of large-area devices, achieve good industrialization prospects, and the preparation method is simple and easy line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Spray PEDOT:PSS solution on a transparent conductive substrate, and heat at 150°C for 10 minutes to prepare a hole transport layer; place the substrate on a heating plate and heat it to 100°C, spray PbI 2 and CH 3 NH 3 40wt% butyrolactone solution of I and heated for 30min; then sprayed with 2mol / L PCBM chlorobenzene solution; finally sprayed with alcohol solution of silver nanowires and heated at 100°C for 5min to obtain a perovskite solar cell.

Embodiment 2

[0025] Spray PEDOT:PSS solution on a transparent conductive substrate, and heat at 100°C for 15 minutes to prepare a hole transport layer; place the substrate on a heating plate and heat it to 100°C, and first spray a layer containing 1mol / L PbI 2 DMF solution and heated for 30min, then sprayed with 10mg / ml of CH 3 NH 3 I isopropanol solution and heated for 30min; then spray 2mol / L PCBM chlorobenzene solution; finally spray the alcohol solution of silver nanowires and heat at 100°C for 5min to obtain a perovskite solar cell.

Embodiment 3

[0027] Spray PEDOT:PSS solution on a transparent conductive substrate, and heat at 180°C for 5min to prepare a hole transport layer; place the substrate on a heating plate and heat it to 100°C, while spraying a solution containing 1mol / L PbI 2 DMF solution and CH containing 1mol / L 3 NH 3 I isopropanol solution and heated for 30min; then spray 2mol / L PCBM chlorobenzene solution; finally spray the alcohol solution of silver nanowires, and heat at 100°C for 5min to obtain a perovskite solar cell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com