Secondary cell, method for manufacturing secondary cell, positive electrode for secondary cells, method for manufacturing positive electrode for secondary cell, battery pack, electronic device, and electric vehicle

A secondary battery and manufacturing method technology, which is applied in battery electrodes, secondary batteries, electrode manufacturing, etc., can solve problems such as poor dispersion, low coating density, and poor coating properties, and achieve increased productivity, high performance, and manufacturing The effect of process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0038] 1. Embodiment 1 (the positive pole that lithium-sulfur battery is used and the manufacture method of positive pole);

Embodiment approach 2

[0039] 2. Embodiment 2 (lithium-sulfur battery);

Embodiment approach 3

[0040] 3. Embodiment 3 (lithium-sulfur battery and manufacturing method of lithium-sulfur battery).

[0041] 1. Implementation Option 1

[0042] Positive electrode for lithium-sulfur batteries

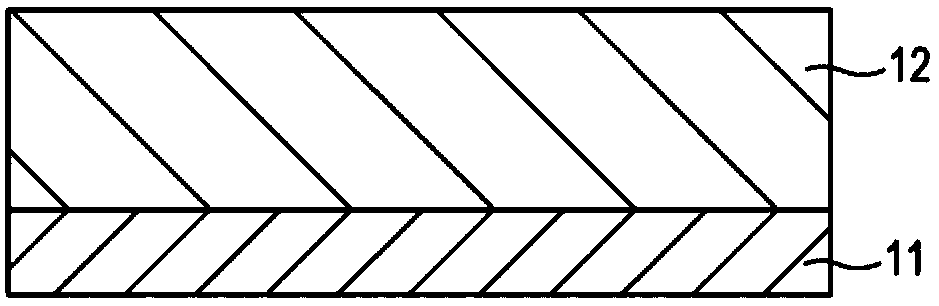

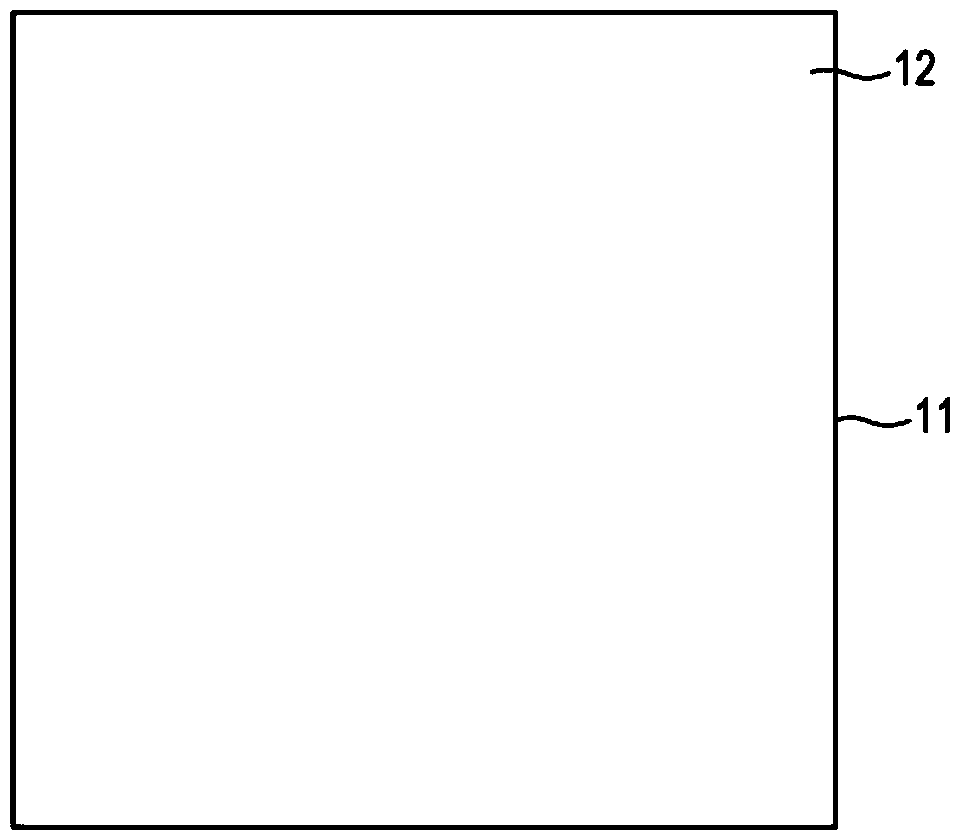

[0043] Figure 1A is a cross-sectional view of a positive electrode for a lithium-sulfur battery according to Embodiment 1. Figure 1B is a plan view of the positive electrode for the same lithium-sulfur battery.

[0044] Such as Figure 1A and Figure 1B As shown, the positive electrode for this lithium-sulfur battery has a conductive substrate 11 and a layer containing insoluble sulfur (insoluble sulfur layer 12). The insoluble sulfur layer 12 generally contains any one of: insoluble sulfur and a conductive agent; or insoluble sulfur, a conductive agent and a binder. The content of insoluble sulfur is preferably 50% by weight or more, for example, 60% by weight or more; however, these parameters of composition and content of insoluble sulfur are not limited thereto. For example,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com