Novel water boiling kettle

A kettle, a new technology, applied in the field of tea sets, can solve the problems of wasting raw materials, not having other uses, increasing production costs, etc., to achieve the effects of reducing production processes, improving water quality and taste, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

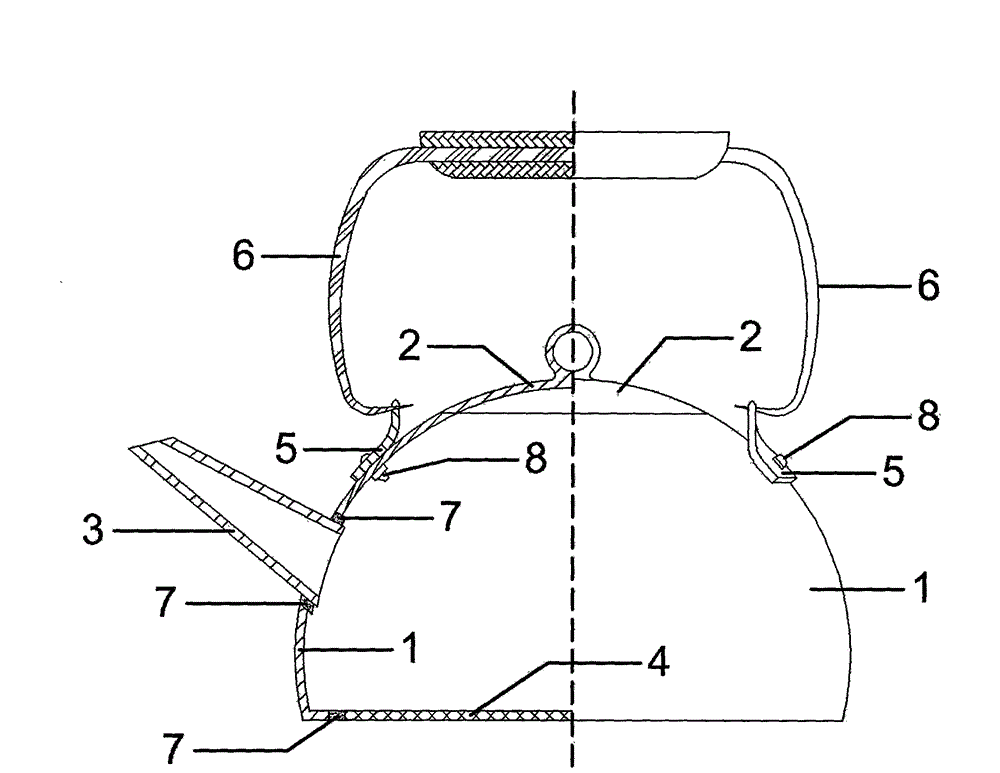

[0035] Embodiment 1: as Figure 1~2 As shown, a new type of boiling kettle includes a rough clay pot body 1, the top of the rough clay pot body 1 is covered with a metal pot lid 2, the side is provided with a metal spout 3, and the bottom is a round pig iron discus 4; The body of the stone clay pot is also connected with a handle 6 through a metal connector 5;

[0036] There is a water outlet on the side of the rough clay pot body 1, and the metal spout 3 is connected to the water outlet of the rough clay pot body 1 through the colloid 7;

[0037] The bottom surface of the rough clay pot body 1 has a discus fixed opening, and the round pig iron discus 4 is connected with the rough clay pot body 1 discus fixed opening through the colloid 7;

[0038] The rough clay pot body 1 has a fixing hole, and the metal connector 5 is connected with the rough clay pot body 1 fixing hole by a screw 8;

[0039] The pot lid 2 and the spout 3 are made of brass, and the metal connector 5 is ma...

Embodiment 2

[0042] Embodiment 2: Different from Embodiment 1, the described rough clay pot body is to get 73% deep layer natural soil, 6% sand, 1.9% bamboo powder, 3% medical stone powder according to weight percentage , 0.08% magnesium powder, and 0.02% zinc powder are mixed, and then 16% water is added to smelt mud to form mud bars, and then the smelted mud bars are cut into small pieces and thrown into the fixed pot under the ceramic rolling machine. The model tank, the model tank is kept at a low temperature of 10°C; then start the rolling machine, the roller head of the rolling machine starts downward, rolls the mud into the internal shape of the model, and then the roller head upwards, takes out the model, opens and takes out The finished pottery body; after drying the pottery body, fire it at 250°C for 28 minutes, wait for the bamboo powder to burn slowly to form pores, then cool it to 7°C within 3 minutes and keep it warm for 70 minutes, and finally raise the temperature to 1050°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com