Heart valve implantation device provided with anchoring device

A heart valve and anchoring device technology, applied in the field of medical devices, can solve problems such as insufficient insertion force, unstable fixation, and lack of a heart valve implantation device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

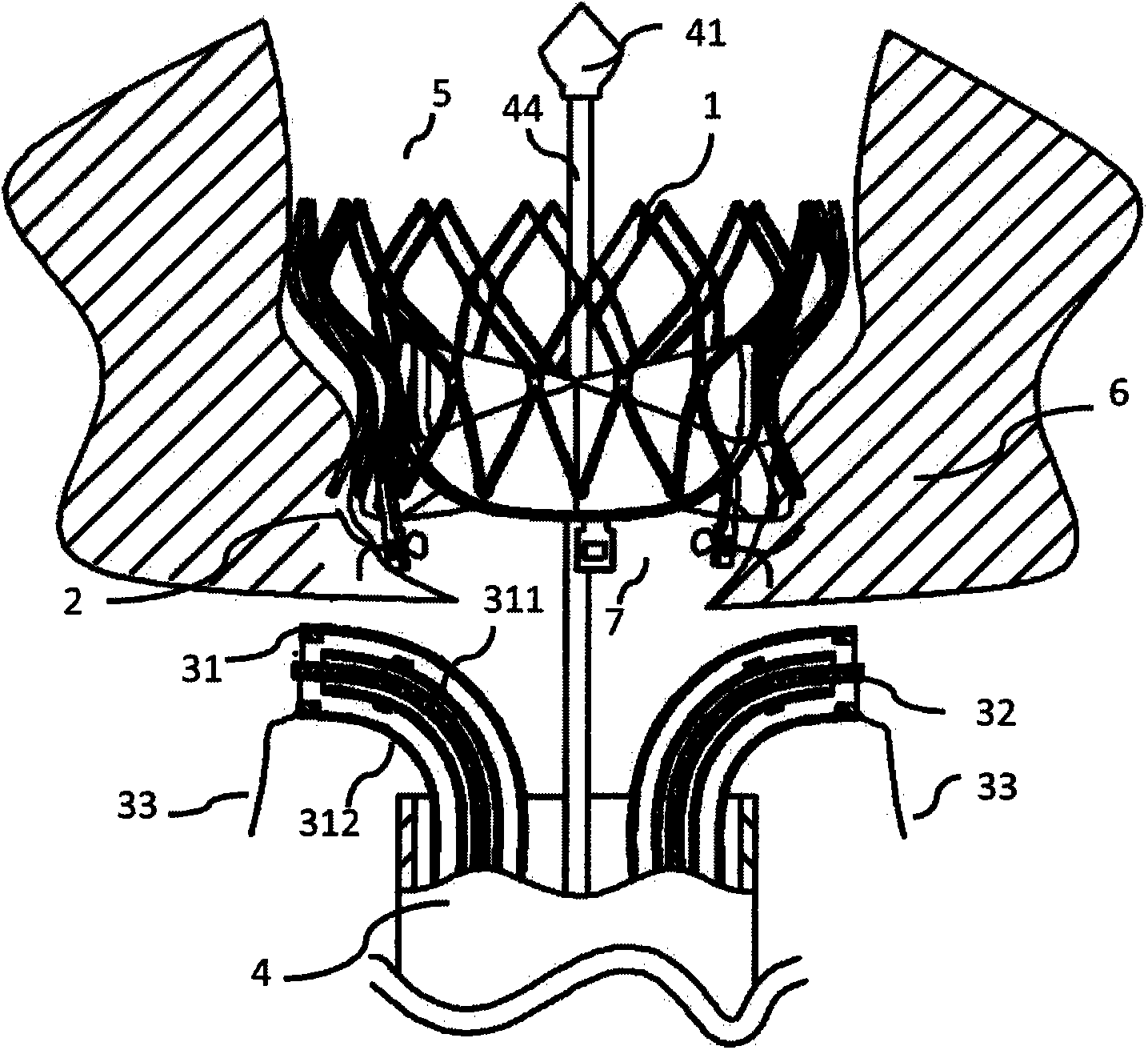

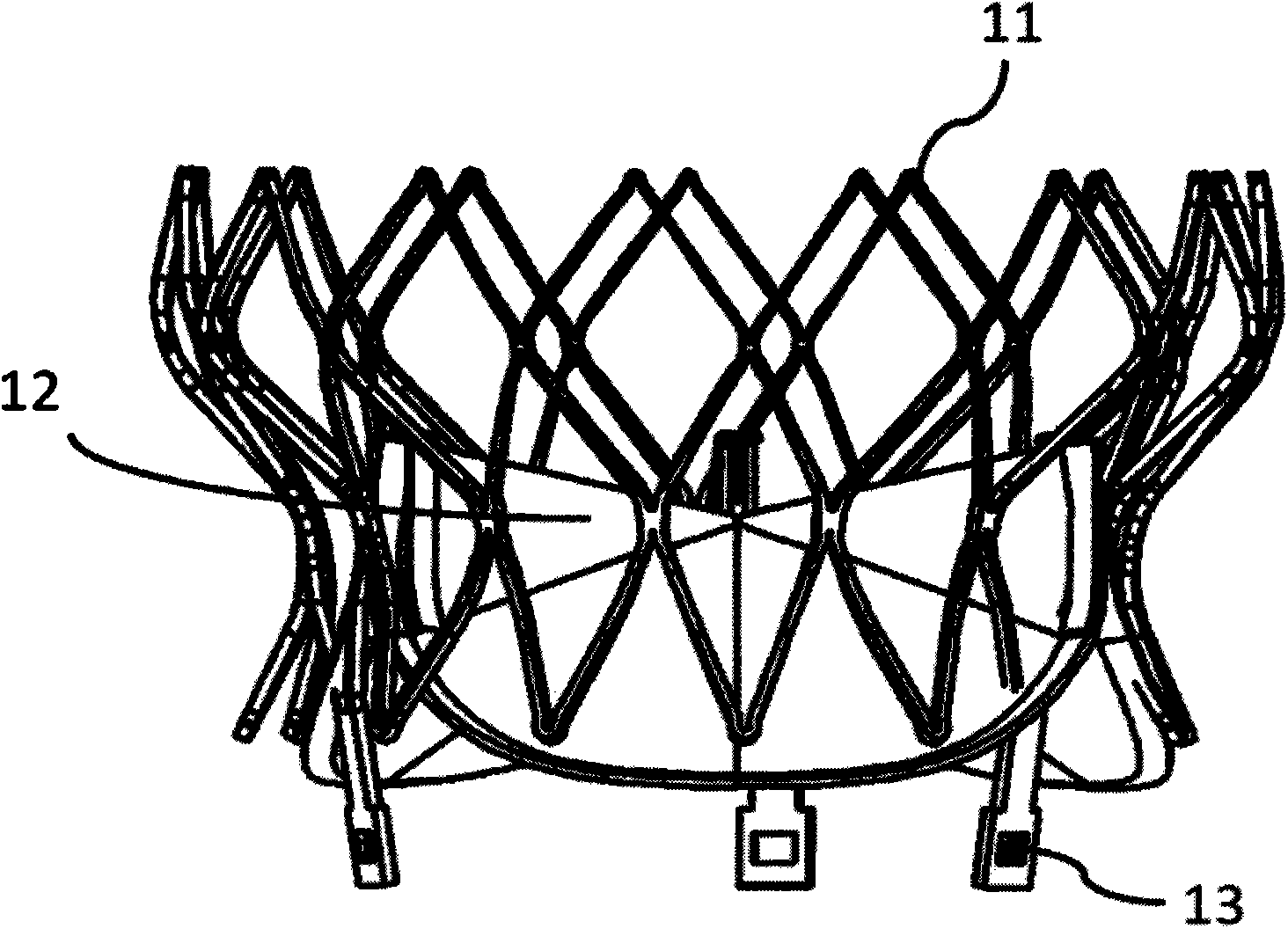

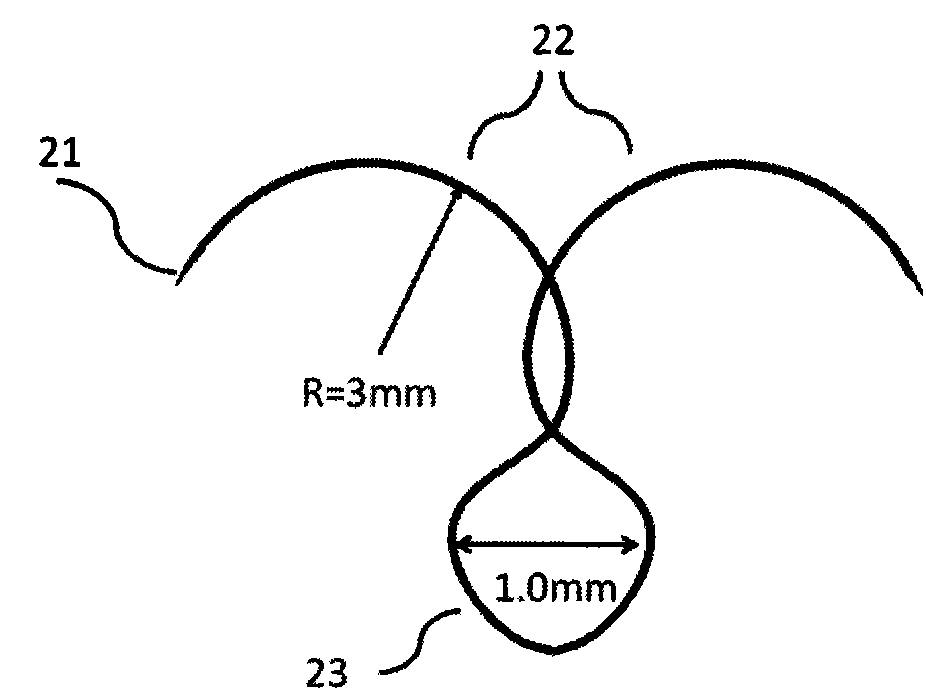

[0050] Such asFigures 1a-1d and Figures 2a-2g As shown, a heart valve implantation device with an anchoring device according to the present invention includes a heart valve prosthesis 1 , two sets of anchoring needles 2 , two sets of anchoring needle release devices 3 and a delivery system 4 . Such as Figure 1a As shown, the two sets of anchor needle release devices 3 are distributed symmetrically. Such as Figure 1b As shown, the heart valve prosthesis 1 is a prosthesis for mitral valve replacement, including a valve frame 11, a valve 12, and an anchoring area 13. The valve frame 11 is cut from a shape-memory nickel-titanium alloy tube and preheated into a shape. The valve 12 is firmly fixed on the valve frame 11, the valve 12 is made of porcine pericardium, and the anchoring area 13 is made of Dacron film, which is fixed on the heart valve prosthesis 1. near end. Such as Figure 1c As shown, the anchoring needle 2 is made of a shape memory nickel-titanium wire with a ...

specific Embodiment 2

[0052] Such as Figures 3a-3e As shown, a heart valve implantation device with an anchoring device according to the present invention includes a heart valve prosthesis 1 , four sets of anchoring needles 2 , four sets of anchoring needle release devices 3 and a delivery system 4 . Such as Figures 3a-3c As shown, the heart valve prosthesis 1 is a prosthesis for tricuspid valve replacement, which is suitable for tricuspid valve replacement surgery through the transapical approach, and the four sets of anchor needle release devices 3 are evenly distributed on the circumference. The difference between this embodiment and the first embodiment is that the valve 12 is made of polymer membrane, and the anchoring position, that is, the anchoring area 13 is located near the atrium 5 . Such as Figure 3d As shown, the anchoring needle 2 is made of a shape memory nickel-titanium wire with a diameter of 0.35 mm, the most distal end 21 of the anchoring needle 2 is sharp, and the distal pa...

specific Embodiment 3

[0054] Such as Figures 5a-5bAs shown, a heart valve implantation device with an anchoring device according to the present invention includes a heart valve prosthesis 1, three sets of anchor needles 2, three sets of anchor needle release devices 3, a delivery system 4 and a set of Support device 8.

[0055] preferred, such as Figure 5a and 5c As shown, the heart valve prosthesis 1 is a prosthesis for mitral valve repair, and is suitable for mitral valve repair surgery through the transapical approach. The difference between this embodiment and the second embodiment is that the valve frame 11 is formed by winding shape-memory nickel-titanium alloy wire and preheated and shaped, and the valve 12 is made of polymer membrane and fixed on the The valve frame 11 extends into the ventricle 7, and the valve 12 moves together with the autologous valve leaflets to prevent the valve leaflets from turning into the atrium 5 due to the prolapse of the chordae tendineae when the autologo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com