Self-relieving chemical reaction kettle capable of being suitable for microwave working environment

A technology of chemical reaction kettle and working environment, which is applied in the field of chemical analysis instruments, and can solve the adverse effects that the sealing cover cannot provide the stability of the pressure relief point of the elastic deformation digestion tank, the mechanical properties of PFA or PTFE change greatly, and the experimental precision and accuracy and other issues, to achieve the effect of ensuring flexibility and reliability, good sealing, and flexible movements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below with reference to the accompanying drawings.

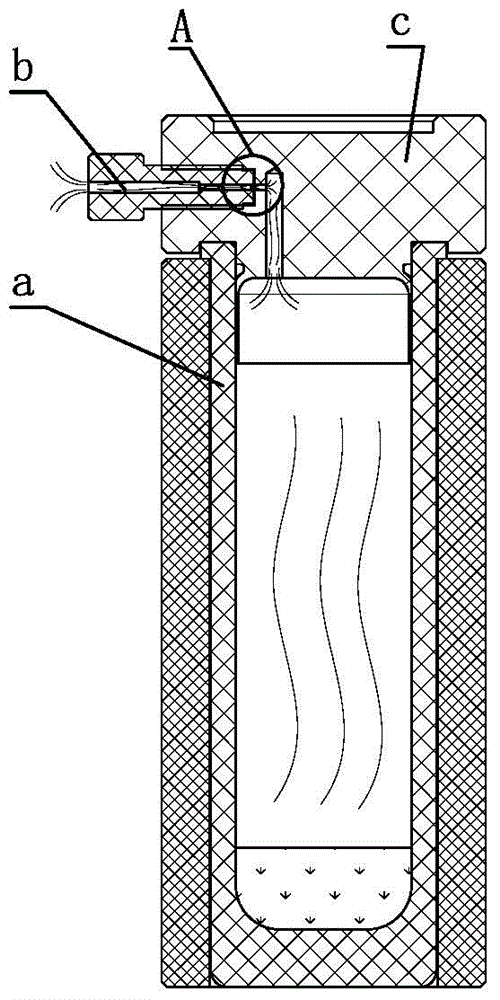

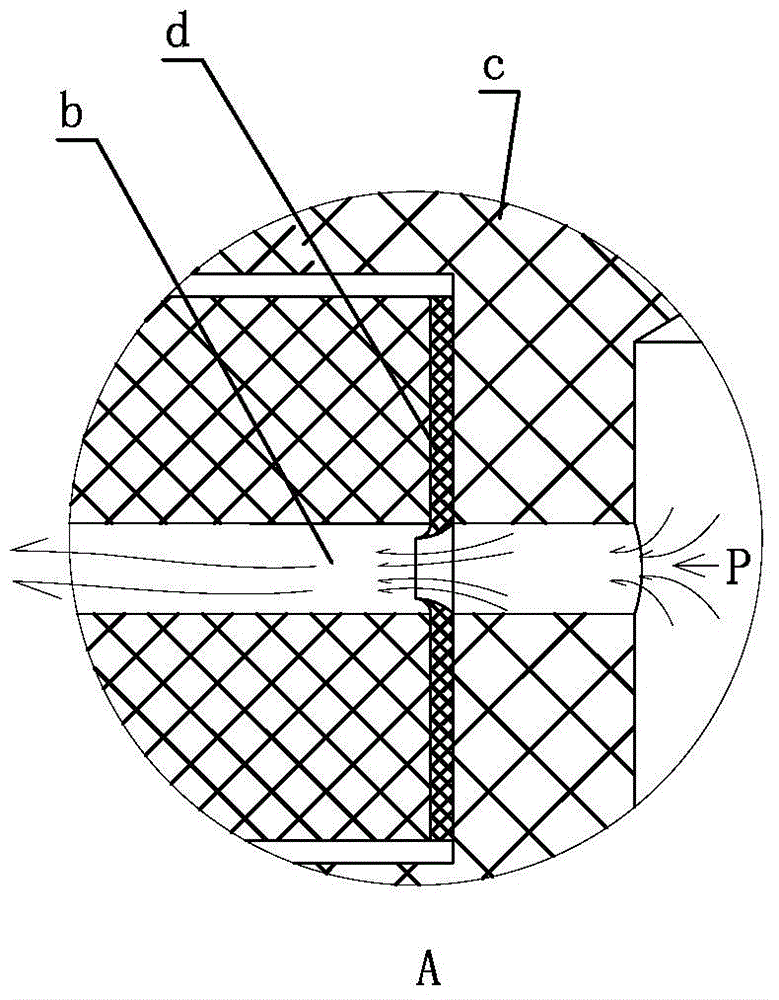

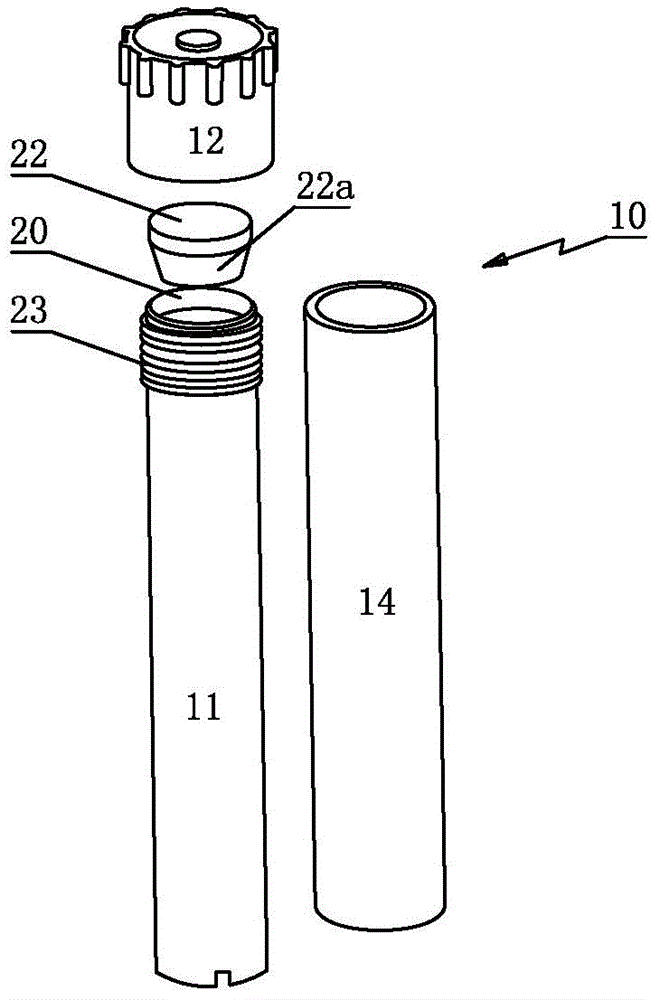

[0067] Figure 4 , Figure 5 and Image 6 Among them, the technical solution of the present invention provides a self-releasing chemical reaction kettle suitable for a microwave working environment, comprising a sleeve 1 and a sample-dissolving cup 2 located in the sleeve. The inner cavity of the sample-dissolving cup is In order to carry the reagent liquid, a sealing cover 4 is arranged on the top of the sleeve, and a first detachable connection structure 7-1 is arranged between the inner wall of the lower end of the sealing cover and the outer wall of the top of the sleeve. The tops are integrally connected by a first detachable connection structure.

[0068] On the upper end of the sample dissolution cup or sleeve, a sealing plug 3 with a central pressure-guiding hole is arranged, and the sealing plug is arranged between the top opening of the sample dissolution cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com