HDPE (high-density polyethylene) winding and reinforcing structural wall B-type pipe molding machine capable of demolding automatically

A technology of winding reinforcement and automatic demoulding, applied in the field of HDPE winding reinforced structural wall B-shaped pipes, can solve the problems of high equipment price and operating cost, difficult demoulding process, product length limitation, etc., and achieve cost saving and effective Conducive to marketing and lower prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

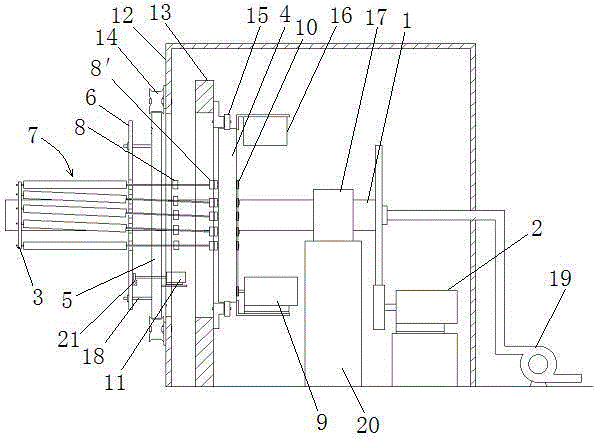

[0022] Such as figure 1 A B-type pipe forming machine with HDPE winding and reinforced structure wall shown in the automatic demoulding, includes a main shaft 1, the main shaft 1 is horizontally connected to the base 20 through the bushing 17, and one end of the main shaft 1 is driven by the main shaft drive motor 2 Connection, from the connection between the main shaft 1 and the bushing 17 to the other end of the main shaft 1, the multi-axis gearbox 4, the mold angle guide plate 6, the main shaft tray 5 and the tail plate 3 are connected coaxially in sequence, and the multi-axis gearbox 4 and The main shaft tray 5 is fixedly connected to the main shaft 1, the mold angle guide plate 6 and the tail plate 3 are rotatably connected to the main shaft 1, and at least four directional wheels 14 are evenly connected to the peripheral edge of the main shaft tray 5, and the directional wheels 14 The wheel shaft is connected on the wall plate 12 arranged on one side of the main shaft tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com