Preparation method for patterned thin film electret

An electret, patterned technology, applied in gaseous chemical plating, manufacturing of microstructure devices, processes for producing decorative surface effects, etc. The charging technology is not applicable, etc., to achieve the effect of good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

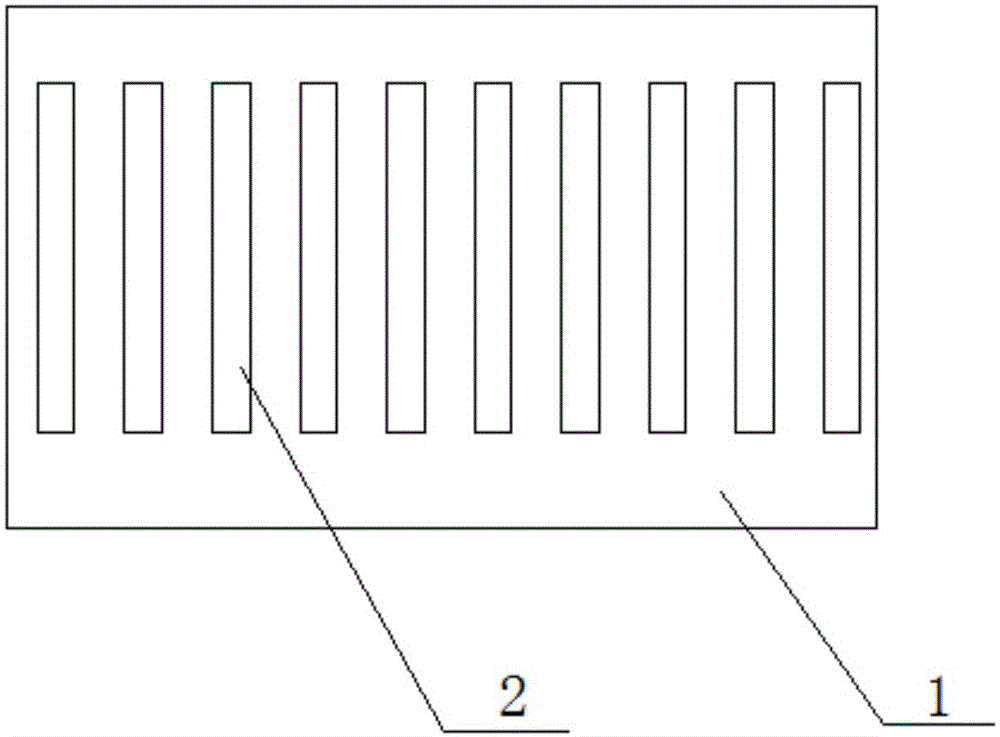

[0033] refer to figure 1 , after the polyfluoroethylene propylene (FEP) film is cleaned by ultrasonic waves, an aluminum electrode (the first metal electrode) with a thickness of 100 nm is evaporated on the lower surface of the polyfluoroethylene propylene (FEP) film 1 by thermal evaporation coating method; A grid-type aluminum electrode (second metal electrode) with a thickness of 100nm is vapor-deposited on the surface. The grid-type aluminum electrode is formed by setting five aluminum films at intervals, and the distance between two adjacent aluminum films is 2mm; Spacing array distribution.

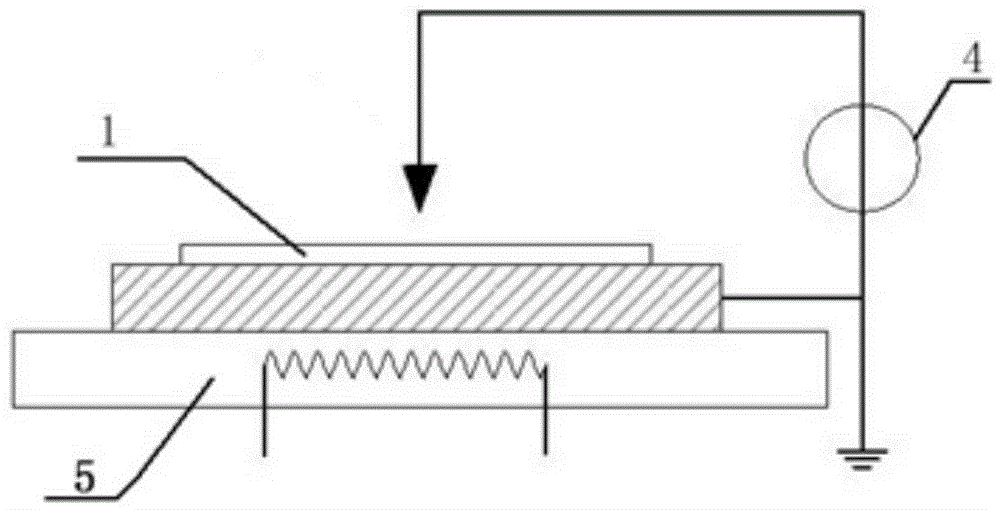

[0034] In order to endow the FEP film with electret properties, it is necessary to use certain means to inject charges into the film body. This process is called injector (also known as charging or polarization). refer to figure 2 , The present invention adopts corona polarization injection pole, adopts AC high-voltage power supply 4 to generate corona discharge, the electric fiel...

Embodiment 2

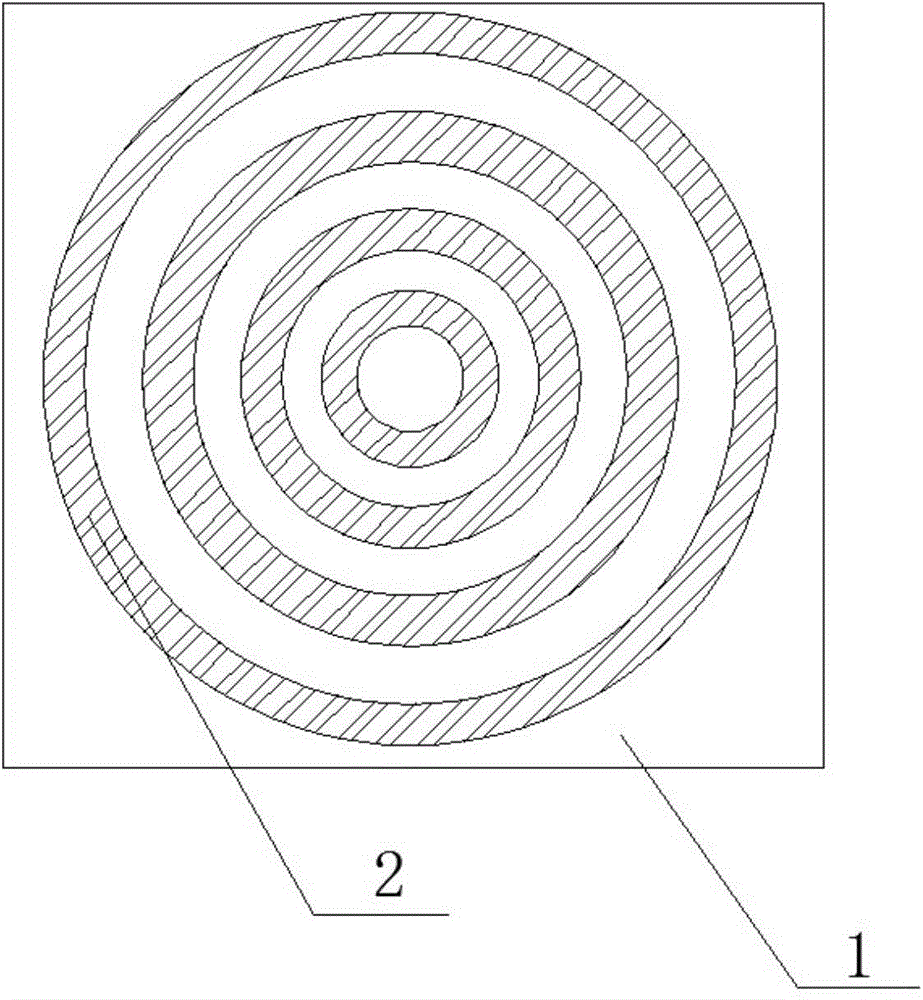

[0038] refer to image 3 , in the second metal electrode, each metal film 2 is a ring arranged concentrically, and the difference between the radii of two adjacent rings is greater than 1 mm. Its polarization method is identical with embodiment 1.

Embodiment 3

[0040] 1. Influence of injector conditions on the charge storage performance of gate electrets

[0041] The present invention compares and studies the effects of methods such as alternating current (AC) corona injection, direct current (DC) corona injection, thermal polarization and the like on the charge storage performance. It is found that only alternating current (AC) corona injectors can form ideal patterned electric field distribution electrets. Although the direct current (DC) corona injector forms a high electret electric field, it cannot display a patterned electric field distribution. The distance between two adjacent aluminum films is 2 mm and 3 mm, respectively, and the temperature of the injection electrode is room temperature, 100 ° C, and 200 ° C, respectively. The initial surface potential values of the patterned FEP electret of the corona injection electrode are shown in Table 1. In addition, it can also be seen from Table 1 that during AC corona injection,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com