High heat-resistant and high-strength drawing slot wedge and preparation method thereof

A high-strength, high-heat-resistant technology, applied in the direction of electromechanical devices, wind power generation, electrical components, etc., can solve the problems of thermal mechanical performance degradation, motor insulation performance degradation, magnetic slot wedge falling off, etc., to achieve high bending strength and resistance Split strength, increase transverse mechanical strength, improve the effect of adhesive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

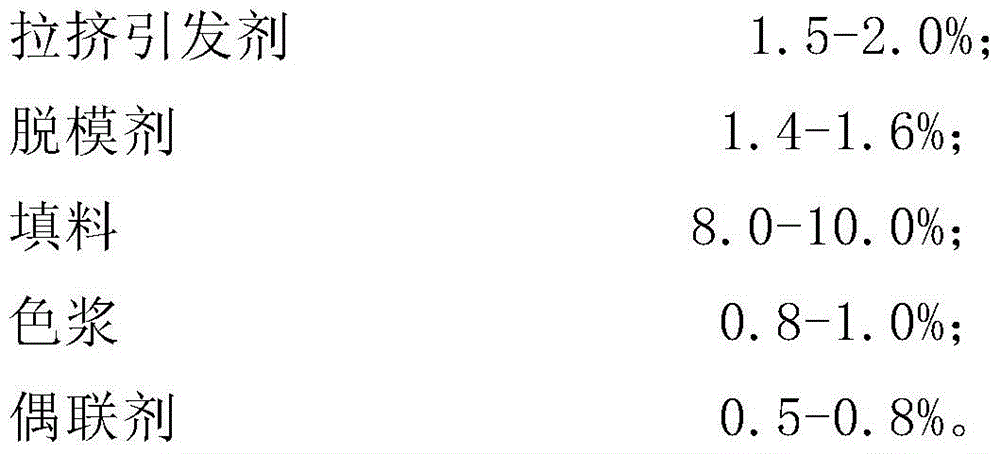

[0018] The high heat-resistant and high-strength pull-out slot wedge has an alkali-free glass fiber cloth and an alkali-free glass fiber yarn in a finished product with a weight percentage of 69%, and a cured adhesive with a weight percentage of 31%.

[0019] In the non-alkali glass fiber cloth and the non-alkali glass fiber yarn, the mass percentages of the non-alkali glass fiber cloth and the non-alkali glass fiber yarn are 33% and 67% respectively.

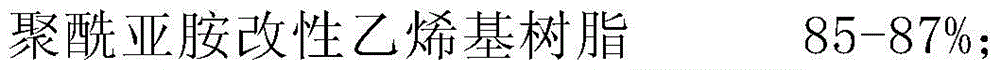

[0020] The adhesive is prepared from the following raw materials by weight percentage: polyimide modified vinyl resin 85%, benzoyl peroxide and tert-butyl peroxybenzoate in the pultrusion initiator are 0.5% and 1.1% respectively, and the demoulding Agent 1.6%, CaCO in filler 3 6%, Al(OH) 3 4%, color paste 1.0%, coupling agent 0.8%.

[0021] Arrange and impregnate the non-alkali glass fiber cloth and non-alkali glass fiber yarn with a weight percentage of 69% in the above-mentioned adhesive in order at room temperature, and co...

Embodiment 2

[0025] The high heat-resisting and high-strength lead slot wedge has an alkali-free glass fiber cloth and an alkali-free glass fiber yarn in a finished product with a weight percentage of 67%, and a cured adhesive with a weight percentage of 33%.

[0026] In the non-alkali glass fiber cloth and the non-alkali glass fiber yarn, the mass percentage ratios of the non-alkali glass fiber cloth and the non-alkali glass fiber yarn are 33% and 67% respectively.

[0027] The adhesive is prepared from the following raw materials: polyimide modified vinyl resin 86%, benzoyl peroxide and tert-butyl peroxybenzoate in the pultrusion initiator are 0.5% and 1.3% respectively, mold release agent 1.6% %, CaCO in filler 3 5%, Al(OH) 3 4%, color paste 0.9%, coupling agent 0.7%.

[0028] Arrange and impregnate the non-alkali glass fiber cloth and non-alkali glass fiber yarn with a weight percentage of 67% in the above-mentioned adhesive in order at room temperature, and control the drawing speed...

Embodiment 3

[0032] The high heat-resistant and high-strength pull-out slot wedge has an alkali-free glass fiber cloth and an alkali-free glass fiber yarn in a finished product with a weight percentage ratio of 66%, and an adhesive weight ratio of 34% after curing.

[0033] In the non-alkali glass fiber cloth and the non-alkali glass fiber yarn, the mass ratios of the non-alkali glass fiber cloth and the non-alkali glass fiber yarn are 33% and 67% respectively.

[0034] The adhesive is formulated from the following raw materials:

[0035] Polyimide modified vinyl resin 87%, benzoyl peroxide and tert-butyl peroxide benzoate in pultrusion initiator are 0.5% and 1.5% respectively, release agent 1.5%, CaCO in filler 3 3%, Al(OH) 3 5%, color paste 0.9%, coupling agent 0.6%.

[0036] Arrange and impregnate the non-alkali glass fiber cloth and non-alkali glass fiber yarn with a weight percentage of 66% in the above-mentioned adhesive in order at room temperature, and control the drawing speed a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com