Filtering purifying method and device for light alloy melt heavy infiltration solid inclusions

A technology for filtering and purifying light alloys, applied in the direction of improving process efficiency, can solve the problems of light alloy melt overflow, reducing filtering efficiency, increasing costs, etc., and achieving the effect of preventing clogging and continuous and smooth filtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: A method for filtering AZ91D light alloy melts and a filtering device thereof. Its filtering method is carried out in the following sequential steps:

[0035] ① Place the preheated AZ91D light alloy in the pre-treatment chamber (2) of the crucible (1) to heat and melt, and raise the temperature to 720°C;

[0036] ②Pretreat the light alloy melt by passing an inert gas with a purity of 99.99% into the light alloy melt;

[0037] ③ The light alloy melt refined by gas blowing passes through the filter mechanism sealed and fixed in the crucible (1) from bottom to top at a flow rate of 0.01 m / s.

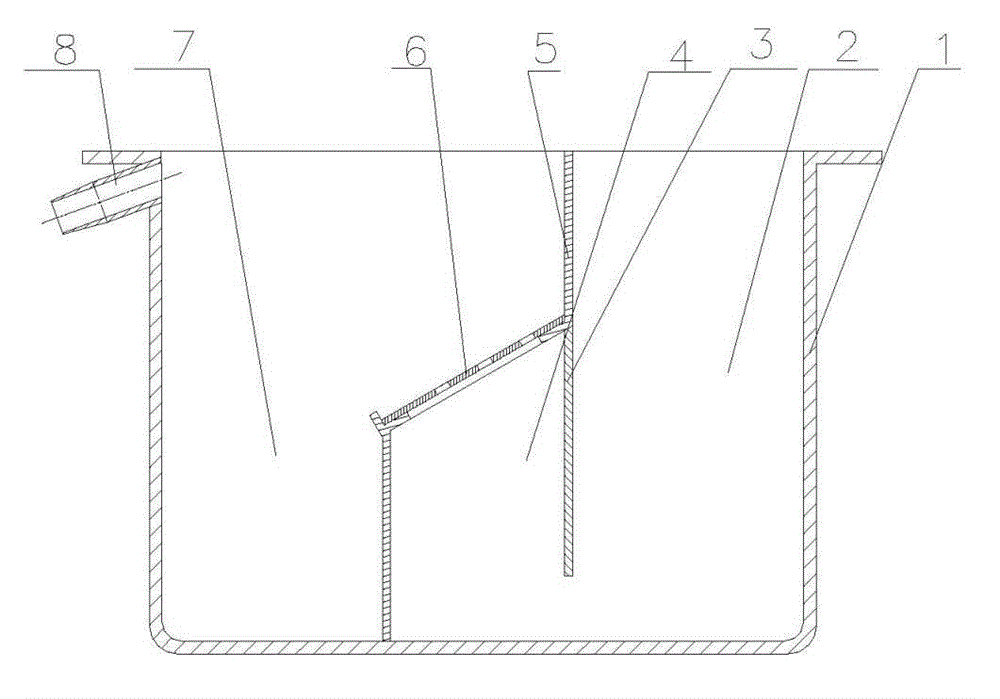

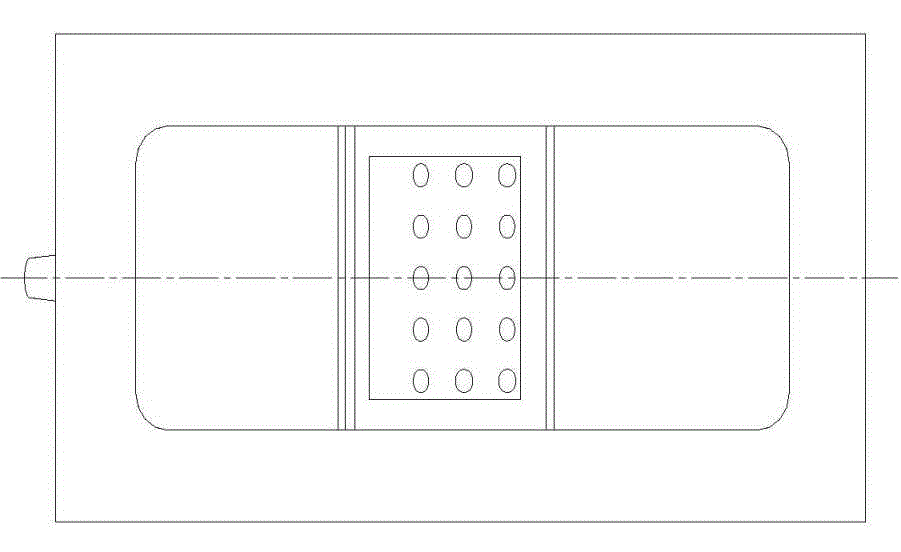

[0038]The filtering device comprises a crucible (1), a partition (3) fixed in the crucible (1), a pretreatment chamber (2) composed of the partition (3) and the crucible (1), and a partition (3) In the crucible (1) between the outlet end (8) of the light alloy melt, there is a filter mechanism sealed and fixed in the crucible (1); the filter mechanism and the partition (...

Embodiment 2

[0039] Embodiment 2: the filtering method of AZ31B light alloy melt and filtering device thereof, its filtering method is carried out in the following sequence steps:

[0040] ① Place the preheated AZ31B light alloy in the pre-treatment chamber (2) of the crucible (1) to heat and melt, and raise the temperature to 750°C;

[0041] ②First pass inert gas with a purity of 99.9% into the light alloy melt, and then pretreat the magnesium alloy melt by standing refining method;

[0042] ③ Make the light alloy melt after the above treatment pass through the filter mechanism sealed and fixed in the crucible (1) from bottom to top at a flow rate of 0.09 m / s.

[0043] The filtering device comprises a crucible (1), a partition (3) fixed in the crucible (1), a pretreatment chamber (2) formed by the partition (3) and the crucible (1), and a partition (3) and In the crucible (1) between the outlet ports (8) of the light alloy melt, a filter mechanism sealed and fixed in the crucible (1) is ...

Embodiment 3

[0044] Embodiment 3: AZ81 light alloy melt filtration method and filter device thereof, its filtration method is carried out in the following sequence steps:

[0045] ① Place the preheated AZ81 light alloy in the pre-treatment chamber (2) of the crucible (1) to heat and melt, and raise the temperature to 710°C;

[0046] ②First, the light alloy melt is pretreated by stirring and refining while blowing gas, and the purity of the inert gas used is 99.99%.

[0047] ③ Make the light alloy melt after the above treatment pass through the filter mechanism sealed and fixed in the crucible (1) from bottom to top at a flow rate of 0.05 m / s.

[0048] The filtering device comprises a crucible (1), a partition (3) fixed in the crucible (1), a pretreatment chamber (2) formed by the partition (3) and the crucible (1), and a partition (3) and In the crucible (1) between the outlet ports (8) of the light alloy melt, a filter mechanism sealed and fixed in the crucible (1) is provided, and the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com