An alkaline galvanized high-purity electroplating solution electroplating pool

A high-purity, electroplating solution technology, used in electrodes, plating tanks, etc., can solve problems such as affecting the stability of the plating solution, easy passivation and insolubility, and affecting electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

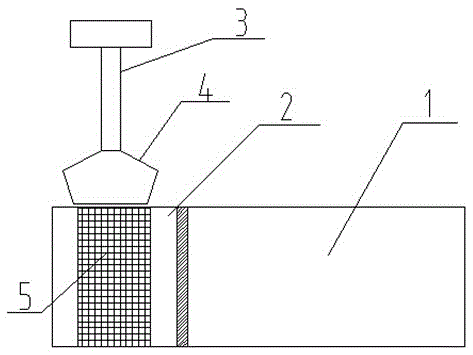

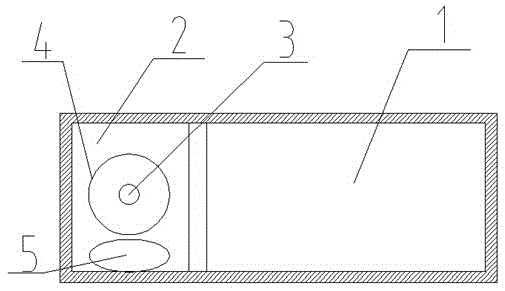

[0014] Such as Figures 1 to 2 An alkaline galvanized high-purity electroplating bath shown includes an electroplating tank, including an electroplating tank, an anode plate, a DC power supply and a plating piece.

[0015] There is electroplating solution in the electroplating tank, and an anode plate installed on the inner wall of the electroplating tank. It also includes an external DC power supply and plating parts. The DC power supply forms a closed circuit with the anode plate, plating parts and electroplating solution through wires.

[0016] The electroplating tank includes an electroplating main tank 1, and a zinc dissolving tank 2 connected to the electroplating main tank 1 through a filter, and also includes an electrolytic cathode 5 vertically arranged on the side wall of the zinc dissolving tank 2, directly above the zinc dissolving tank 2 A telescopic pull rod 3 is set, and an insoluble hanging basket 4 is set at the bottom end of the stretchable pulling rod 3. Zin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com