Construction technology of pipeline suspension cable span bridge body installation

A construction technique and bridge-spanning technology, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., which can solve the problems of large workload, long period and high risk of site leveling and construction, and achieve the effect of strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

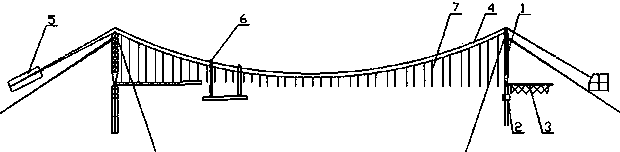

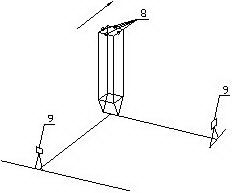

[0046] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

[0047] The crossing of an oil and gas pipeline project needs to cross the river. The landform on the west bank is relatively steep, with an average of 60 degrees, and the river is not navigable. Therefore, if the bridge body is installed using the symmetrical method, a large number of road construction and site leveling work will be required, and the transportation safety risk is high.

[0048] The construction technology for the installation of the pipeline suspension cable spanning the bridge body includes the following contents:

[0049] For the analysis of the process implementation process, the relatively gentle east bank is selected as the sending bank for spanning structure prefabrication, installation and sending, and the bridge body sending platform 3 is set on the east bank.

[0050] According to the sit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com