Plane grating-based system for measuring large-stroke movement of wafer bench

A plane grating and motion measurement technology, applied in the direction of measurement devices, optical devices, instruments, etc., can solve the problems of the limited arrangement of the movement stroke of the silicon wafer stage, and achieve the effect of small errors, reducing restrictions, and avoiding cable interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The principle, structure and specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

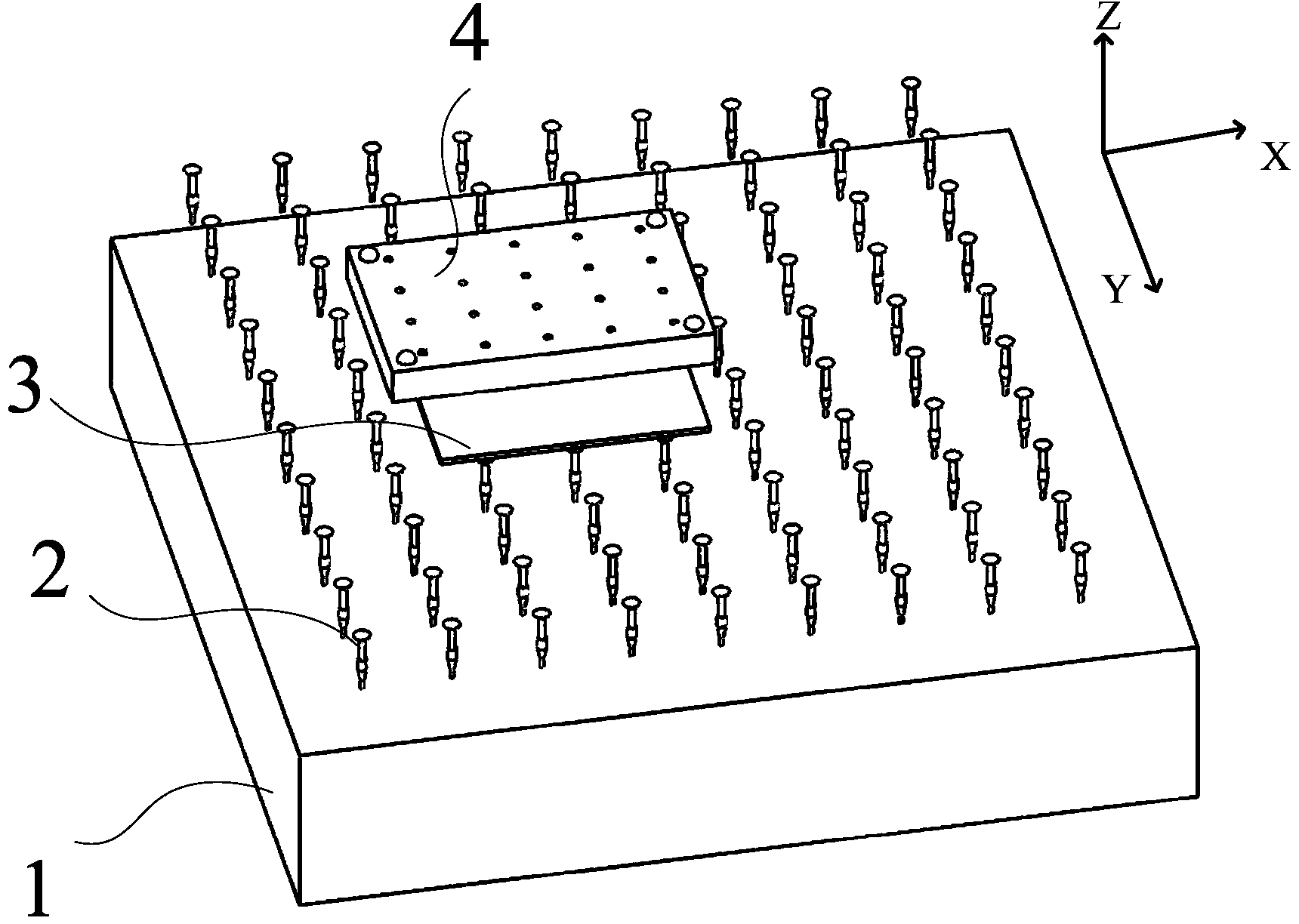

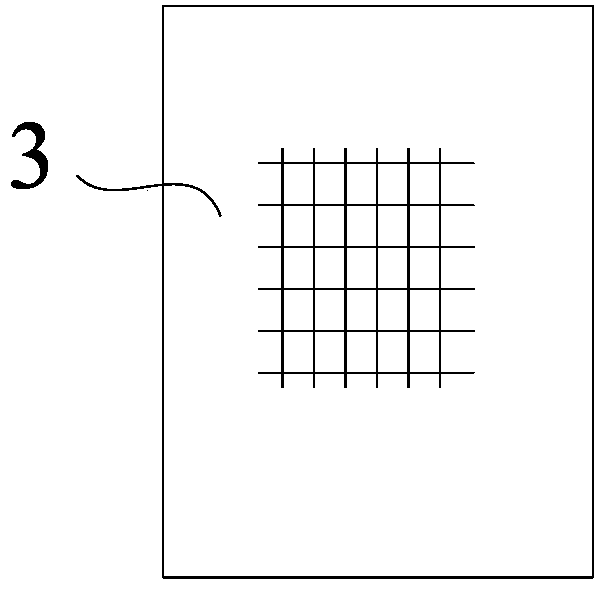

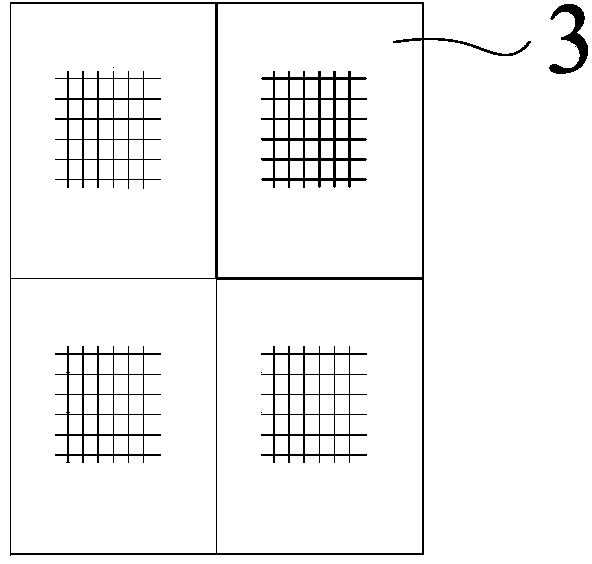

[0015] figure 1 A schematic diagram of a large-stroke motion measurement system for a silicon wafer table based on a planar grating provided by the present invention is given. The motion system includes a silicon wafer table moving table 4 and a silicon wafer table fixed table 1 . The silicon wafer table moving table 4 utilizes an iron-free planar motor as a drive element, and adopts air floatation or magnetic floatation to realize large-scale planar motion. The planar grating 3 is installed on the lower surface of the silicon wafer stage moving table 4, and the measurement surface faces the silicon wafer table fixed table 1, and can be installed by screw connection or bonding. A gap is also reserved between the plane grating 3 and the wafer stage fixing table 1 to avoid damage to the grating during work. The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com