Method for measuring fracture toughness J<IC> of heat affected zone of welded joint

A heat-affected zone and fracture toughness technology, which is used in the preparation of test samples and the application of stable bending force to test the strength of materials to achieve the effect of convenient operation, reducing errors and avoiding material waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The measurement of the fracture toughness J of the heat-affected zone of the welded joint in this embodiment IC The method mainly includes the following steps:

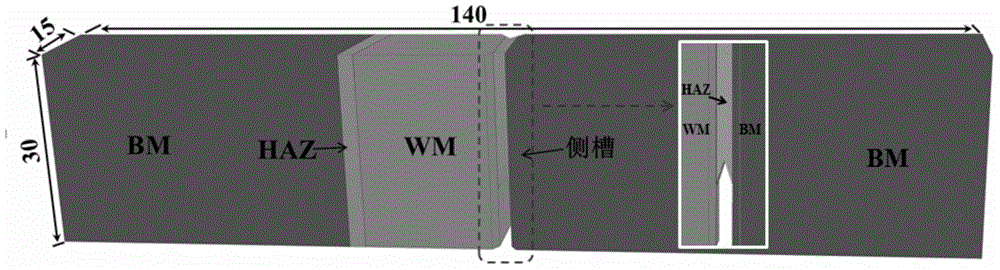

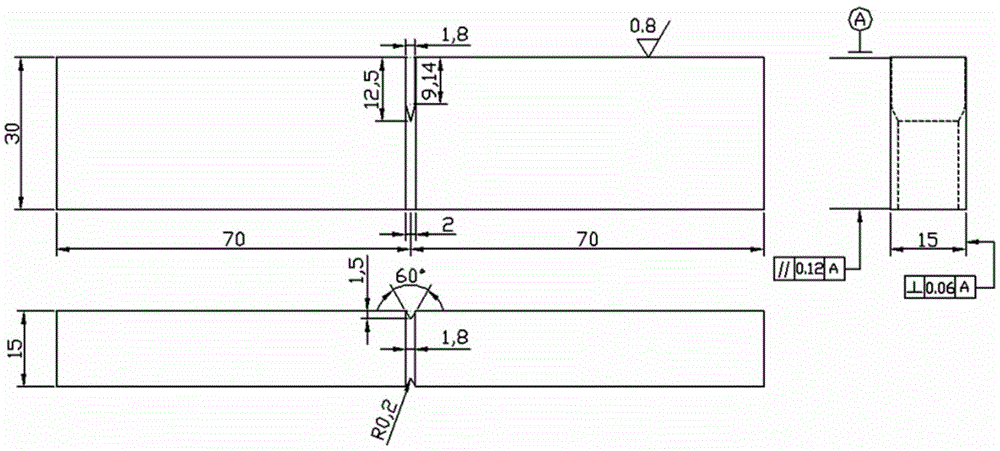

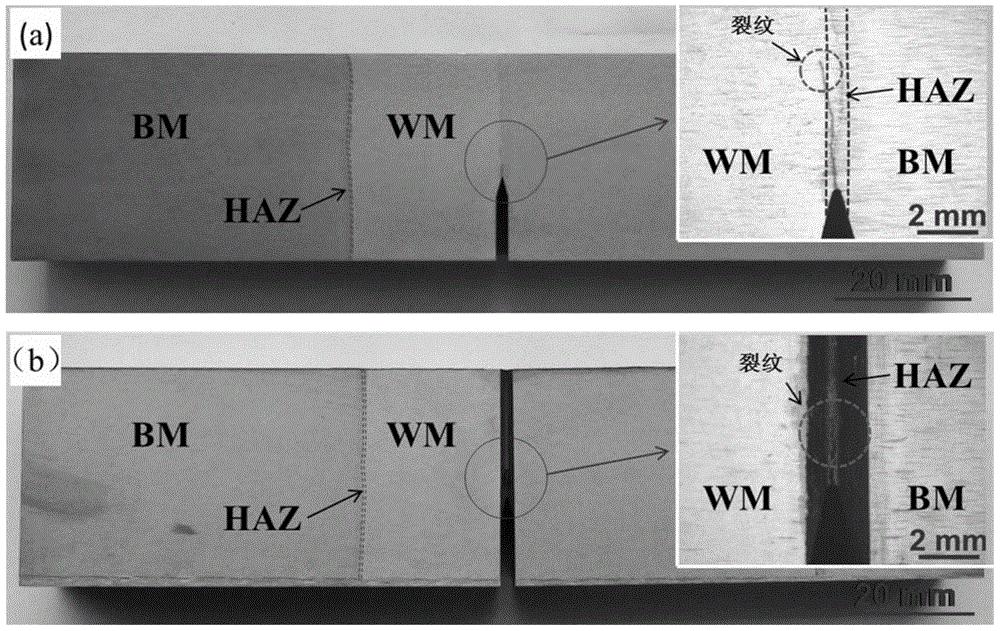

[0028] (1) Taking a sample with a thickness of 15mm as an example, process 8 to 10 three-point bending samples. The three-dimensional schematic diagram of the sample is shown in figure 1 , see the specific size figure 2 , where the depth of the V-groove is 1.5mm, the angle is 60°, and the bottom fillet radius is 0.2mm;

[0029] (2) Perform fatigue crack prefabrication on the three-point bending specimen on the fatigue testing machine, where the maximum load is 10kN, the minimum load is 1kN, the stress ratio R is 0.1, and the fatigue crack length is about 2.0mm;

[0030] (3) Perform a three-point bending test on a universal testing machine, load the first sample to the maximum load, distribute the remaining samples evenly between the maximum load point and the end point of the elastic stage, and perform a thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Bottom radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com