A comprehensive test device for anti-fouling and drag-reducing performance of underwater coatings for ships

A comprehensive testing and coating technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of being unable to simultaneously evaluate the drag-reducing performance of marine bio-adhesion strength and the influence of materials on drag-reducing performance, so as to ensure accuracy, rigorous design, Design scientific and reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

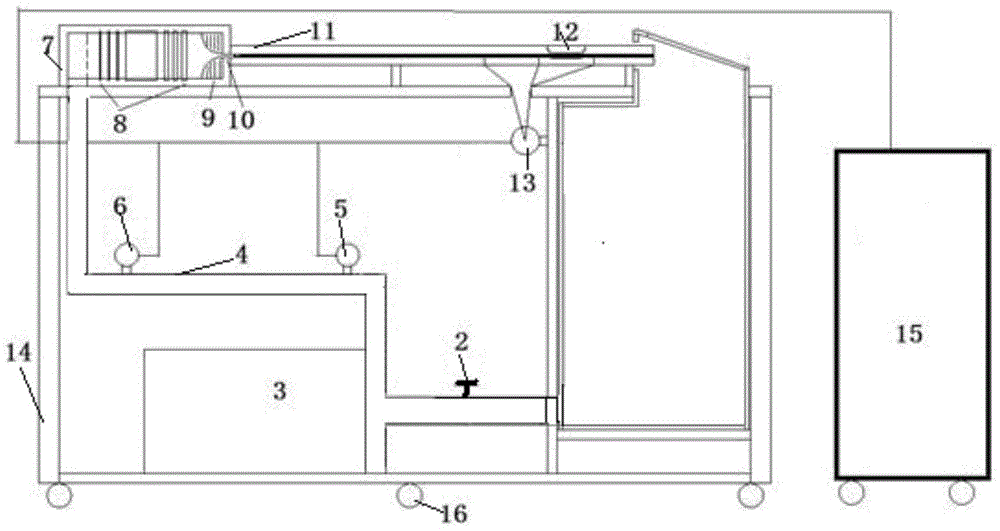

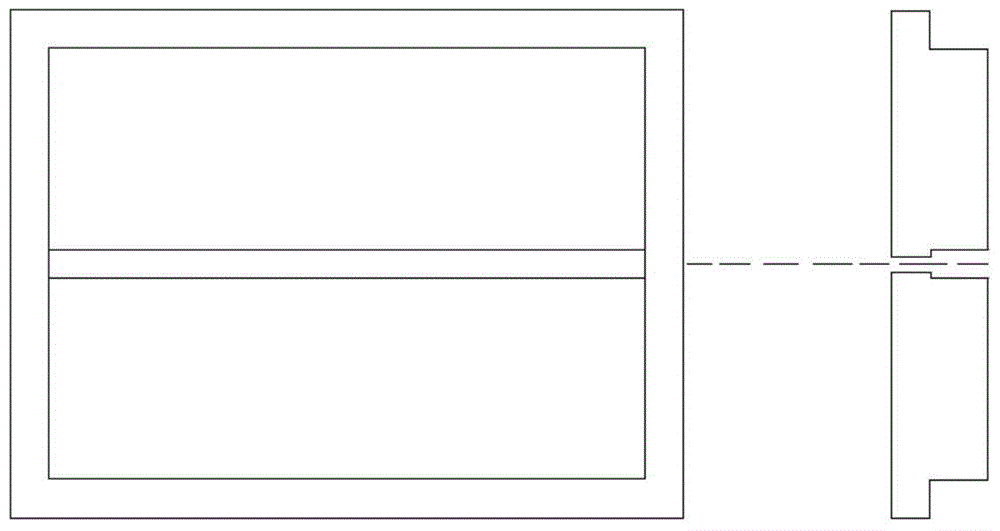

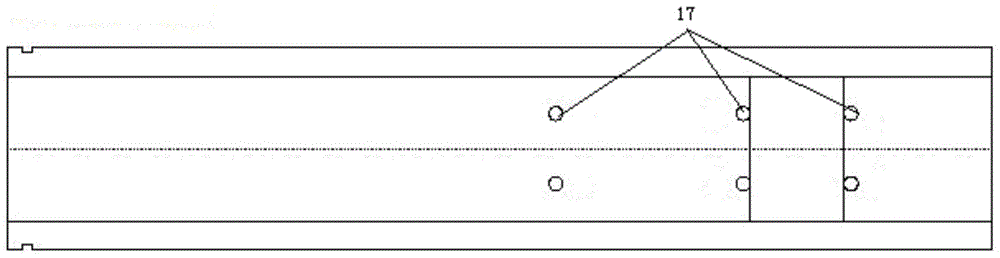

[0023]The main structure of this embodiment includes a water tank 1, a valve 2, a water pump 3, a delivery pipeline 4, a pressure gauge 5, a flow meter 6, a steady flow box 7, a sieve plate 8, a flow diversion box 9, a slit plate 10, Straight slit flow channel 11, sample stage 12, double differential pressure gauge 13, frame 14, control cabinet 15 and casters 16; water tank 1 made of PE material has a volume of 230L, and the water tank 1 is fixedly installed on the frame 14 for containing seawater There is a shock-absorbing rubber pad between the water tank 1 and the frame 14; a valve 2 is formed between the outlet of the water tank 1 and the water pump 3, and the valve 2 controls the on-off of the water flow in the water tank 1, and can be disassembled and replaced; the water pump 3 is made of German For the Steinberg magnetic pump, the water pump 3 is lined with polytetrafluoroethylene, which can effectively prevent seawater corrosion while ensuring the seawater transportatio...

Embodiment 2

[0034] This example uses 1×10 6 Sulphate-reducing bacteria per ml, shake well and set aside; apply the anti-fouling and drag-reducing material on a tinplate sheet with a specification of 100mm*51mm, a total of 6 parallel samples, and put 3 samples into the sample groove at the bottom of the flow channel The other 3 samples are put into the upper plug-in sample stage, and then the sample stage is fixed tightly, the flow rate is set to 7.0m / s, the flushing time is 5min, and the average value of the double differential pressure meter 13 recorded between 104-120H is 233.3Pa Then the sample is placed in the bacterium liquid of the above-mentioned sulfate-reducing bacteria, and it is taken out after 1 hour, and the number of bacteria in 15 fields of view is randomly counted for each sample by a multifunctional biological monitor; then the sample is put into the test device, the set flow rate is 7.0m / s, and the flushing time is 5min. The average value of the double differential press...

Embodiment 3

[0036] This example uses 1×10 6 pieces / ml of benthic diatoms (Spinodes constricta), shake well and set aside; apply the anti-fouling and drag-reducing material on a tinplate sheet with a specification of 100mm*51mm, a total of 3 parallel samples, and place the samples above In the diatom liquid, take it out after 1 hour, and use a multifunctional biological monitor to count the number of bacteria in 15 random fields of view for each sample; then put the sample into the sample stage, fix it tightly, and set the flow rate to 0.5m / s, the flushing time is 5min, and the shear force is calculated as 0.46Pa by the average value of the differential pressure transmitter 78-104H from the formula (2). The number of bacteria in the field was counted; the desorption rates of sulfate-reducing bacteria on the three samples were calculated by formula (1) to be 2.0%, 1.5%, and 1.3%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com