Large chemical process distributed modeling method based on CCA-PLS

A technology of chemical process and modeling method, which is applied in the direction of instruments, adaptive control, control/regulation system, etc., and can solve the problems of model structure complexity and precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

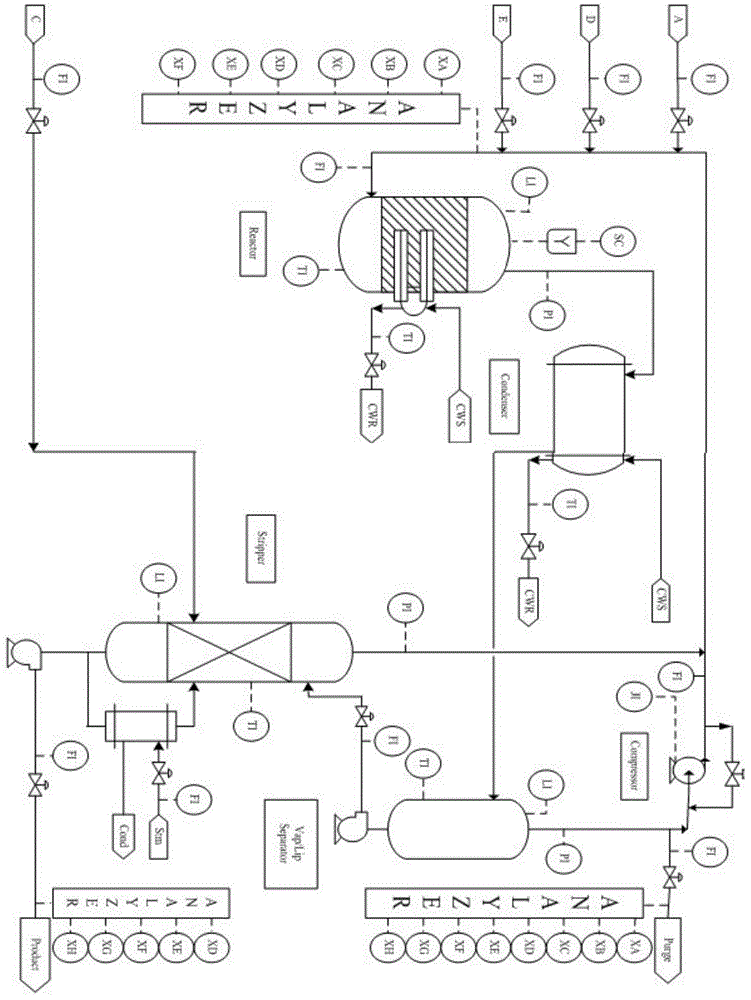

[0062] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

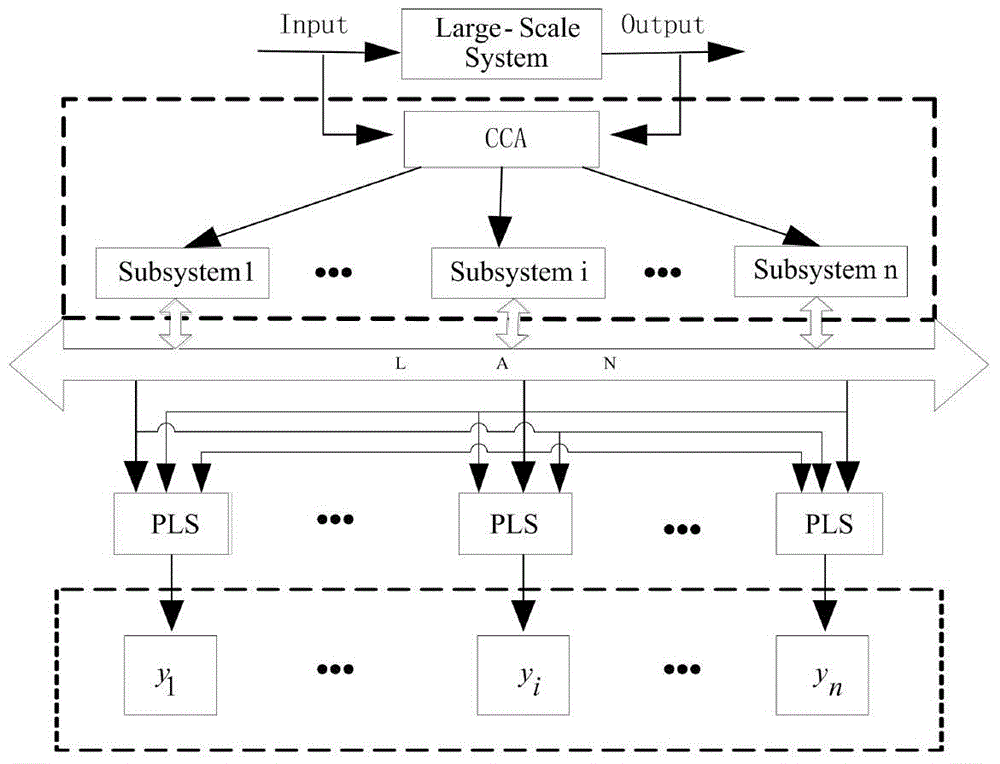

[0063] The technical scheme adopted in the present invention is as figure 2 shown.

[0064] The distributed modeling algorithm based on Canonical Correlation Analysis (CCA) [11] and Partial Least Squares (PLS) [12] is divided into two stages: large system decomposition based on CCA and modeling of each subsystem based on PLS. For the large-scale chemical process, all the process variables are firstly collected, the important variables closely related to the process quality are selected as the system output variables, and the rest of the process variables are used as the system input. Due to the large number of variables in the large chemical process, there are multiple correlations and collinearity among the variables, and the variable information is redundant. If all the input variables are directly used for modeling, the model structure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com