Reconstruction wafer structure with bared chip back and manufacturing method thereof

A chip and backside technology, which is applied to the reconstructed wafer structure and manufacturing field exposed on the backside of the chip, can solve the problems of high cost and low cost, and achieve the effects of low cost, easy heat dissipation, and process saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] In order to enable those skilled in the art to understand the present invention in more detail, the present invention will be described in detail below in conjunction with the accompanying drawings.

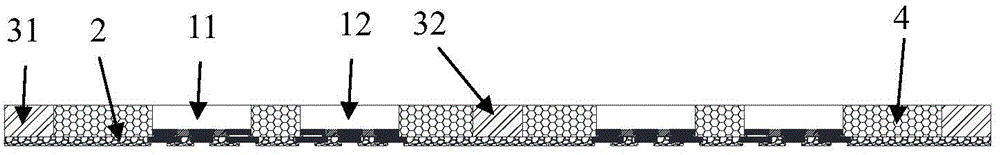

[0032] Such as figure 1 said, figure 1 It is a reconstituted wafer structure with an exposed chip backside in an embodiment of the present invention, wherein the structure includes:

[0033] the first chip 11;

[0034] second chip 12;

[0035] Rewiring layer 2, the first chip 11 and the second chip 12 are disposed on the rewiring layer 2, wherein the first chip 11 and the second chip 12 are a distance from the rewiring layer 2 by a distance of distance a;

[0036] The first height-limiting block 31 and the second height-limiting block 32, the first height-limiting block 31 and the second height-limiting block 32 are arranged on the rewiring layer 2, wherein the first height-limiting block 31 There is a second distance b between the second height limiting block 31 and ...

Embodiment 2

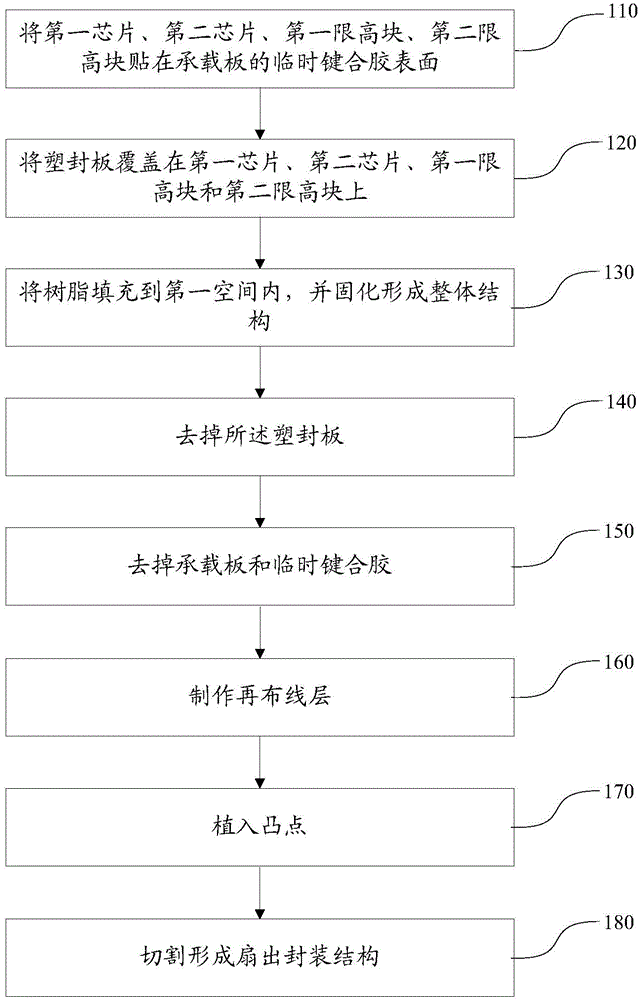

[0046] Such as Figure 2-10 As shown, the embodiment of the present invention also provides a method for fabricating a reconstructed wafer structure with an exposed chip backside, the method comprising:

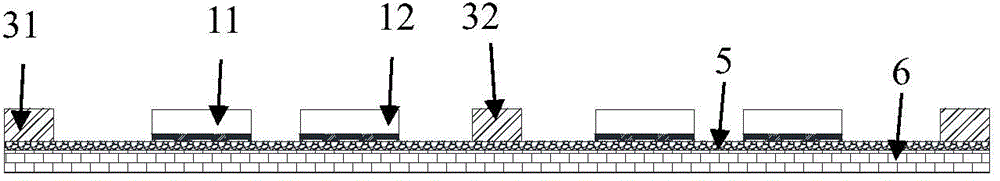

[0047] Step 110: paste the first chip 11, the second chip 12, the first height limiting block 31, and the second height limiting block 32 on the surface of the temporary bonding glue 5 of the carrier board 6;

[0048] Step 120: Cover the plastic sealing plate 7 on the first chip 11, the second chip 12, the first height limiting block 31 and the second height limiting block 32;

[0049] Step 130: filling the resin 4 into the first space, and curing to form an integral structure;

[0050] Step 140: removing the plastic sealing plate 7;

[0051] Step 150: remove the bearing plate 6 and the temporary bonding glue 5;

[0052] Step 160 : Fabricate the redistribution layer 2 .

[0053] Further, the method also includes:

[0054] Step 170 : Implant bumps 8 .

[0055] Further, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com