Grounding Pattern Structure For High-frequency Connection Pad Of Circuit Board

A graphic structure, high-frequency welding technology, applied in circuits, printed circuits, printed circuits, etc., can solve the problem of no high-frequency signal transmission, and achieve the effect of reducing the probability of high-frequency differential mode signal transmission errors and the effect of reducing the probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

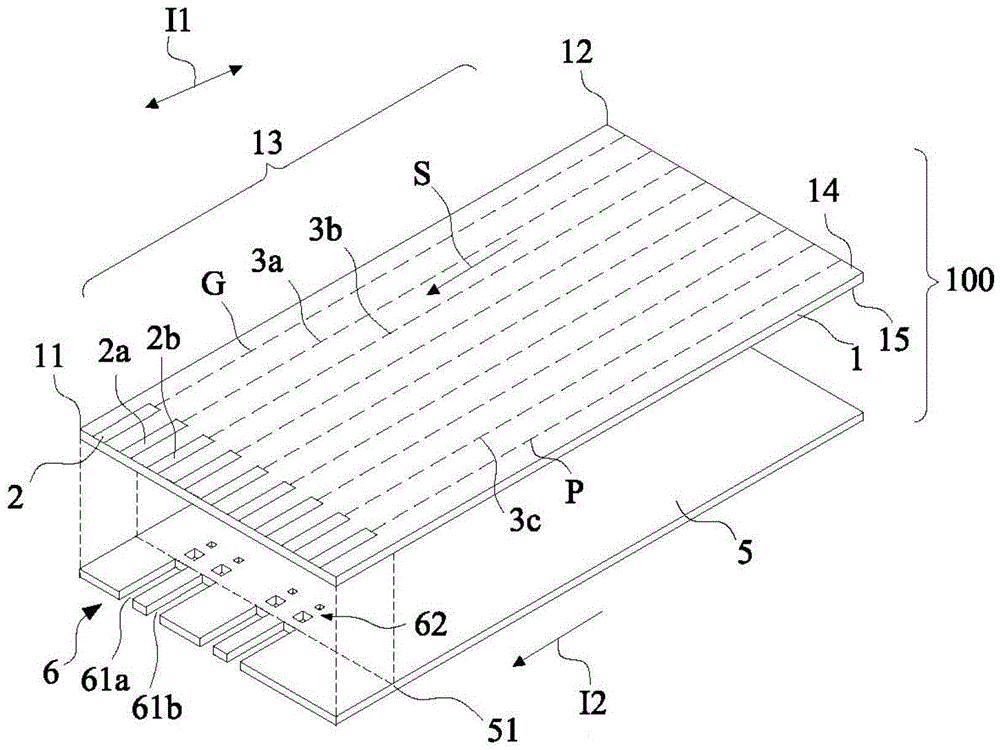

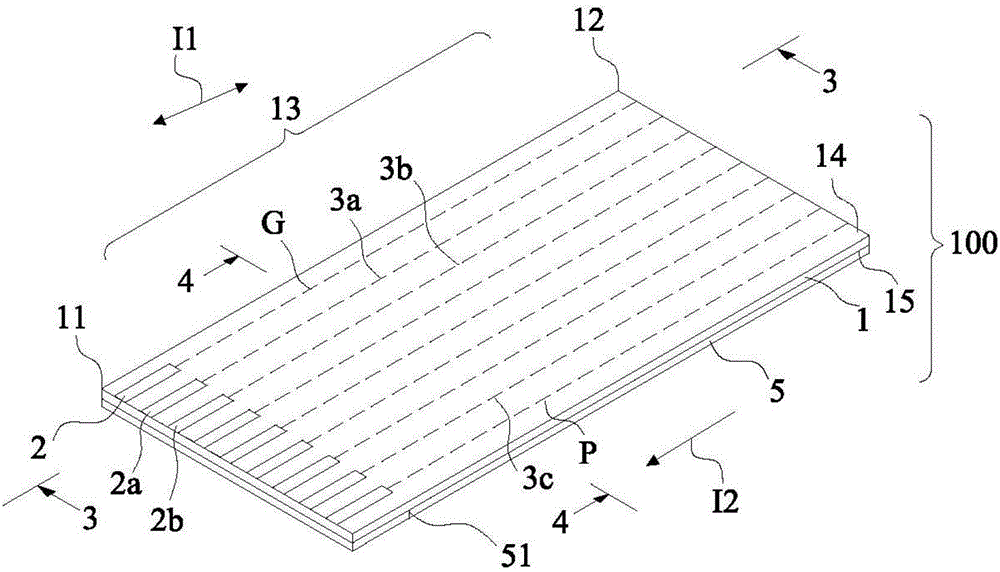

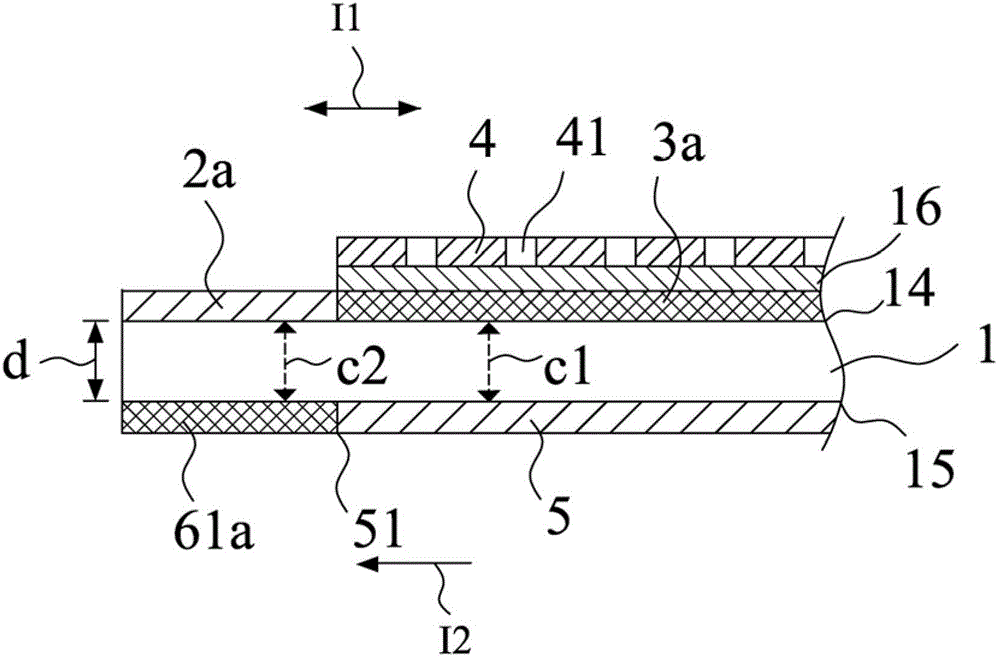

[0077] refer to Figure 1 ~ Figure 2 shown, where figure 1 shows an exploded perspective view of the first embodiment of the present invention, figure 2 A perspective view of a first embodiment of the invention is shown. The circuit board 100 of this embodiment includes a substrate 1, the substrate 1 has a first end 11, a second end 12, and an extending direction I1 between the first end 11 and the second end 12. An extension section 13 .

[0078] A plurality of pad regions 2 are arranged adjacent to each other and insulated on the device surface 14 of the substrate 1 , and adjacent to the first end 11 of the substrate 1 . Each pad area 2 includes at least one pair of high frequency pad areas 2a, 2b.

[0079] The extension section 13 is provided with at least one pair of differential-mode signal lines 3a, 3b for carrying at least one high-frequency differential-mode signal S. As shown in FIG. The differential mode signal lines 3a, 3b are respectively connected to the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com