Attenuation reduction structure for high frequency signal contact pads of circuit board

一种高频信号、连接垫的技术,应用在电气连接印刷元件、印刷电路、印刷电路等方向,能够解决缺少解决方法高频信号传送等问题,达到降低电容效应的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

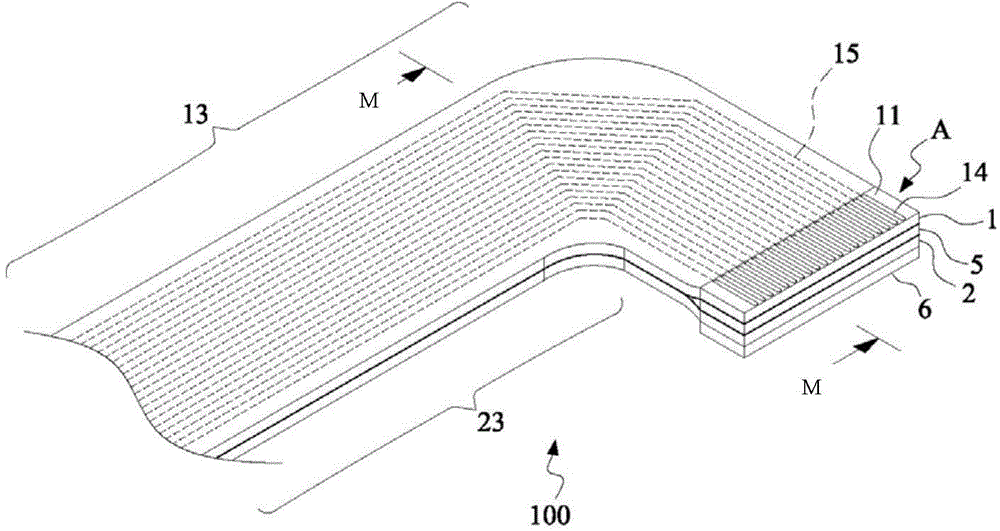

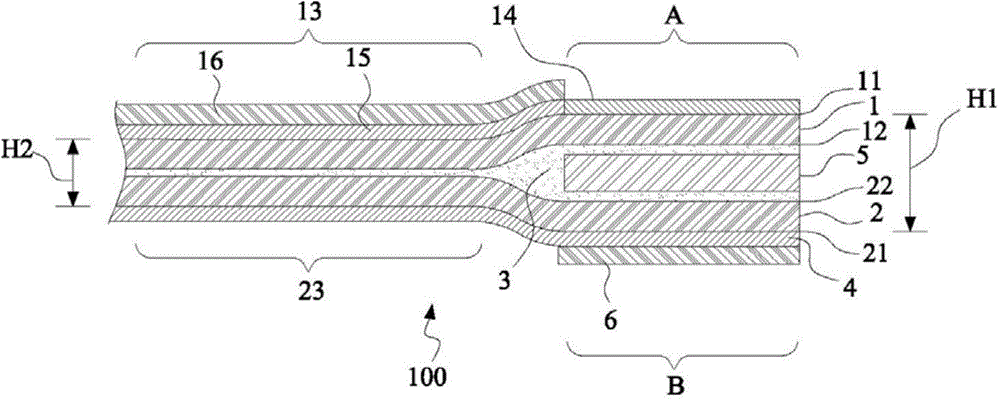

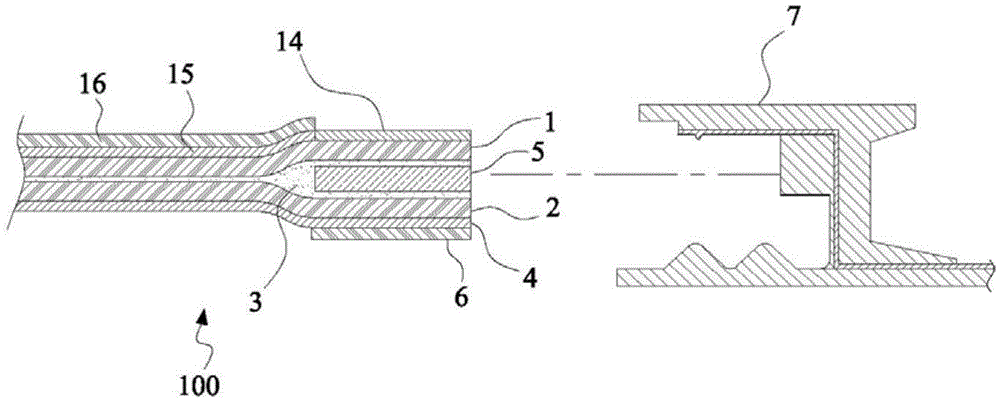

[0063] see figure 1 and figure 2 The circuit board 100 according to the first embodiment of the present invention has a circuit layout surface 11 and a ground wire layout surface 21, and a connection pad layout section A and a connection pad layout section A corresponding to the connection pad layout section A are provided on the circuit layout surface 11. Corresponding section B of . The structure of the circuit board 100 in this embodiment includes a first substrate 1, a second substrate 2, an adhesive layer 3, a ground layer 4, a plurality of high-frequency signal connection pads 14 and a plurality of high-frequency signal lines 15 .

[0064] The first substrate 1 has a circuit layout surface 11 and a first bonding surface 12, wherein the circuit layout surface 11 defines a connection pad layout section A and a first extension extending from the connection pad layout section A. Section 13.

[0065] A plurality of high-frequency signal connection pads 14 are arranged ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com