A kind of preparation method of layer number controllable graphene

A technology of graphene and gas, which is applied in the field of preparation of layer-controlled graphene, can solve the problem of graphene that has not yet existed, and achieve the effect of easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

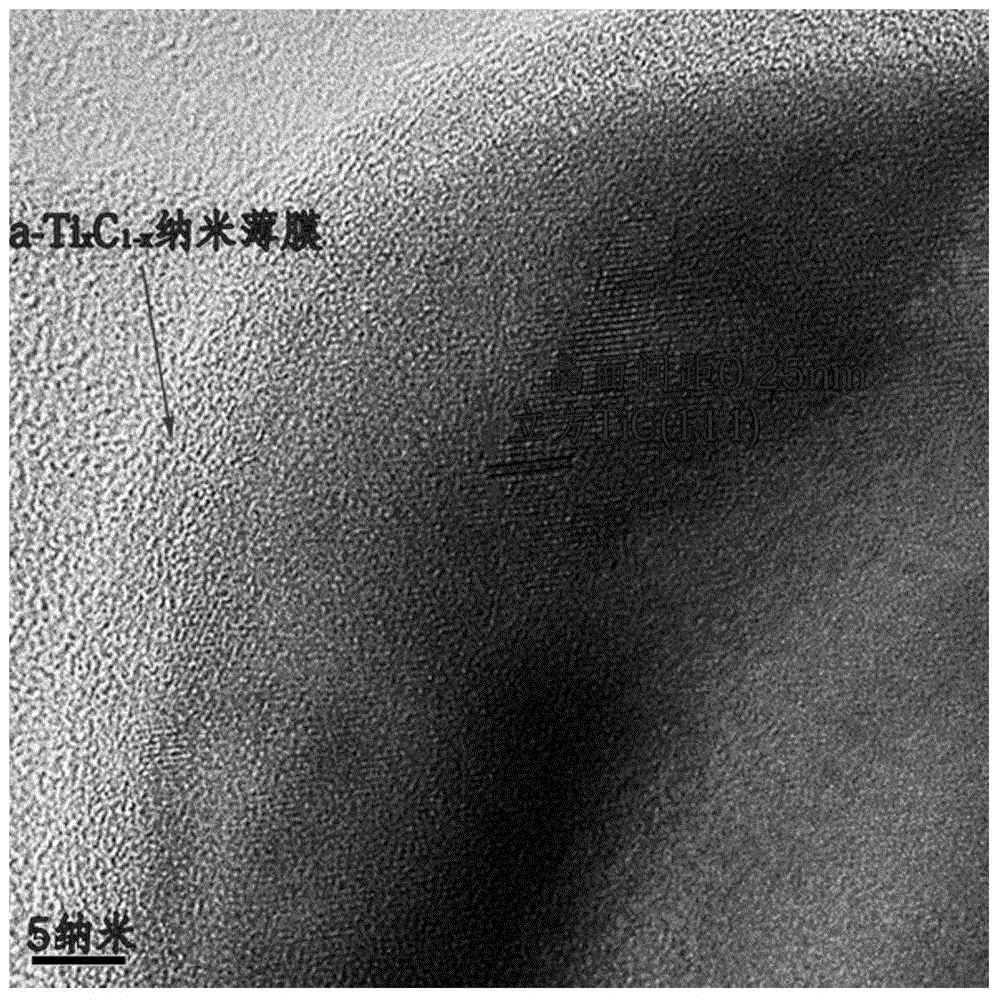

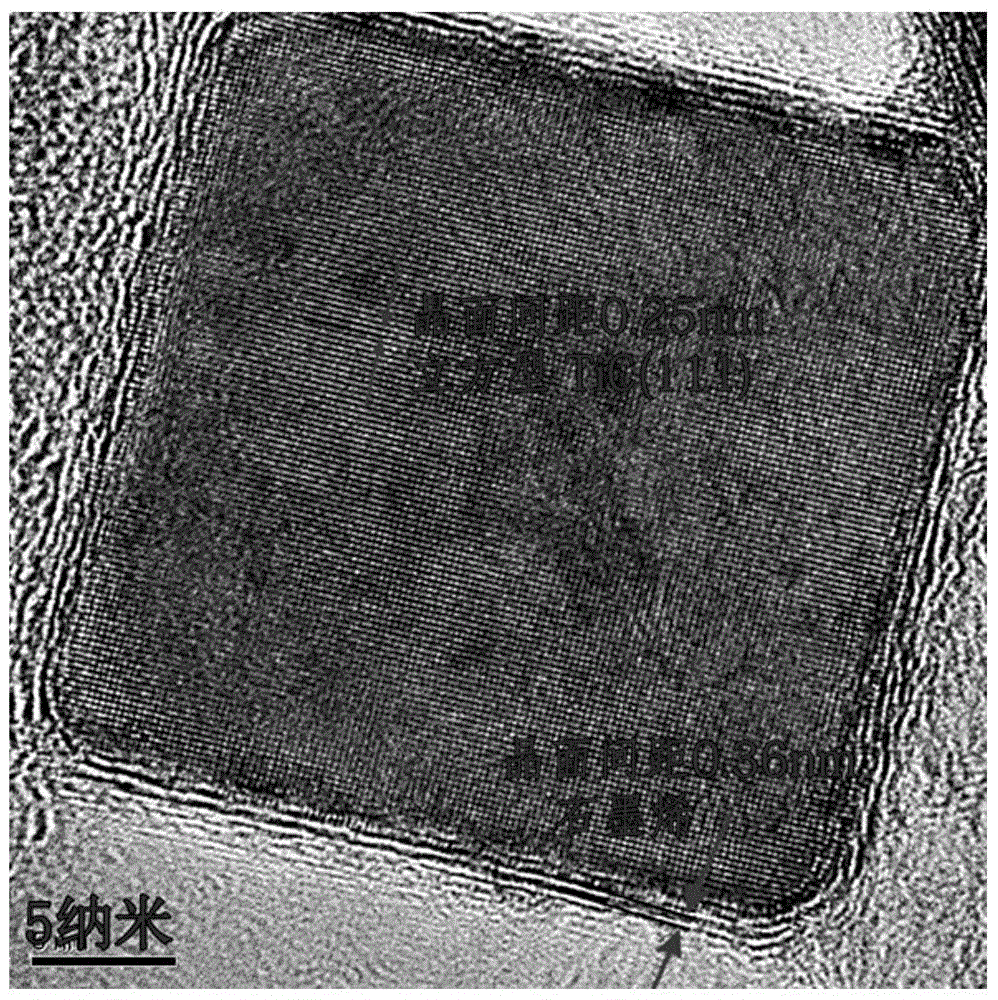

Embodiment 1

[0052] Weigh 2g of a-Ti with amorphous nanoshell on the surface 0.4 C 0.6 After putting it into a quartz tube and sealing it, feed high-purity He gas at a flow rate of 500ml / min for 30 minutes so as to get rid of the air in the quartz tube, heat the furnace to 200 degrees Celsius, and keep the He gas flow rate at Under the premise of 100ml / min, feed Cl at a flow rate of 500ml / min during the reaction 2 Gas, stop feeding Cl after one hour of reaction 2 gas while keeping the He gas flowing in, keeping the reaction temperature at 200° C. for one hour and then lowering it to room temperature to obtain nanoparticles with a graphene structure of 1 to 3 layers on the surface. figure 1 It is a transmission electron microscope image (TEM) of nano-TiC with amorphous nano-film on the surface; as figure 2 It is a transmission electron microscope image of nanoparticles with a 2-layer graphene structure on the surface after halogenation at 200°C in Example 1, wherein the crystalline TiC ...

Embodiment 2

[0054] The preparation process and steps in this example are exactly the same as those in Example 1 above. The difference is: the reaction temperature is 400°C. Finally, nanoparticles with a graphene structure of 2-4 layers on the surface can be obtained.

Embodiment 3

[0056] The preparation process and steps in this example are exactly the same as those in Example 1 above. The difference is: the reaction temperature is 600°C. Nanoparticles with a graphene structure of 4-5 layers on the surface can be finally obtained. Figure 4 After the nano-TiC with amorphous nano-shells on the surface is halogenated at 600°C in Example 3, the transmission electron microscope image of nanoparticles with a 5-layer graphene structure on the surface;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com