Hexagonal boron nitride nano-sheet with controllable layer number, and preparation method thereof

A technology of hexagonal boron nitride and nanosheets, which is applied in chemical instruments and methods, nitrogen compounds, nanotechnology, etc., can solve the problems of polluting the environment, difficult to control the reaction process, and expensive metal substrates, and achieve simple process and high production efficiency. High rate and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A hexagonal boron nitride nanosheet with a controllable layer number is prepared by the following method:

[0027] (1) Preparation of boron precursors containing calcium ions: add 0.1mol boric acid and 0.1mol concentrated ammonia water (about 7.5ml) to 10ml of deionized water in sequence, place them in a constant temperature water bath at 80°C for magnetic stirring, and then add 10 ml of calcium chloride solution with a concentration of 0.1 mol / L was added dropwise, stirred at a constant temperature for 0.5 h, and then placed in an oven at 110° C. for heat treatment for 12 h to obtain a boron precursor containing calcium ions.

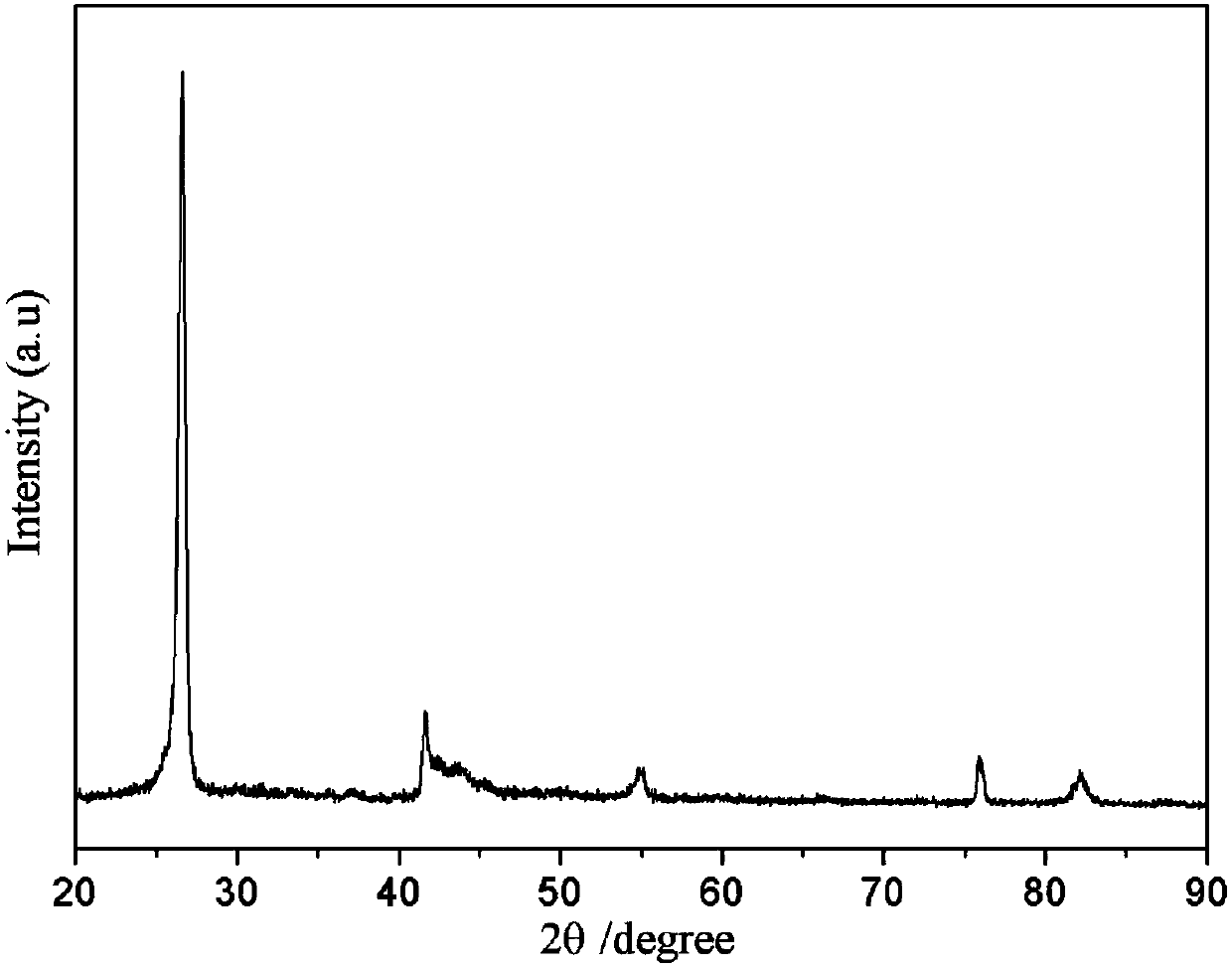

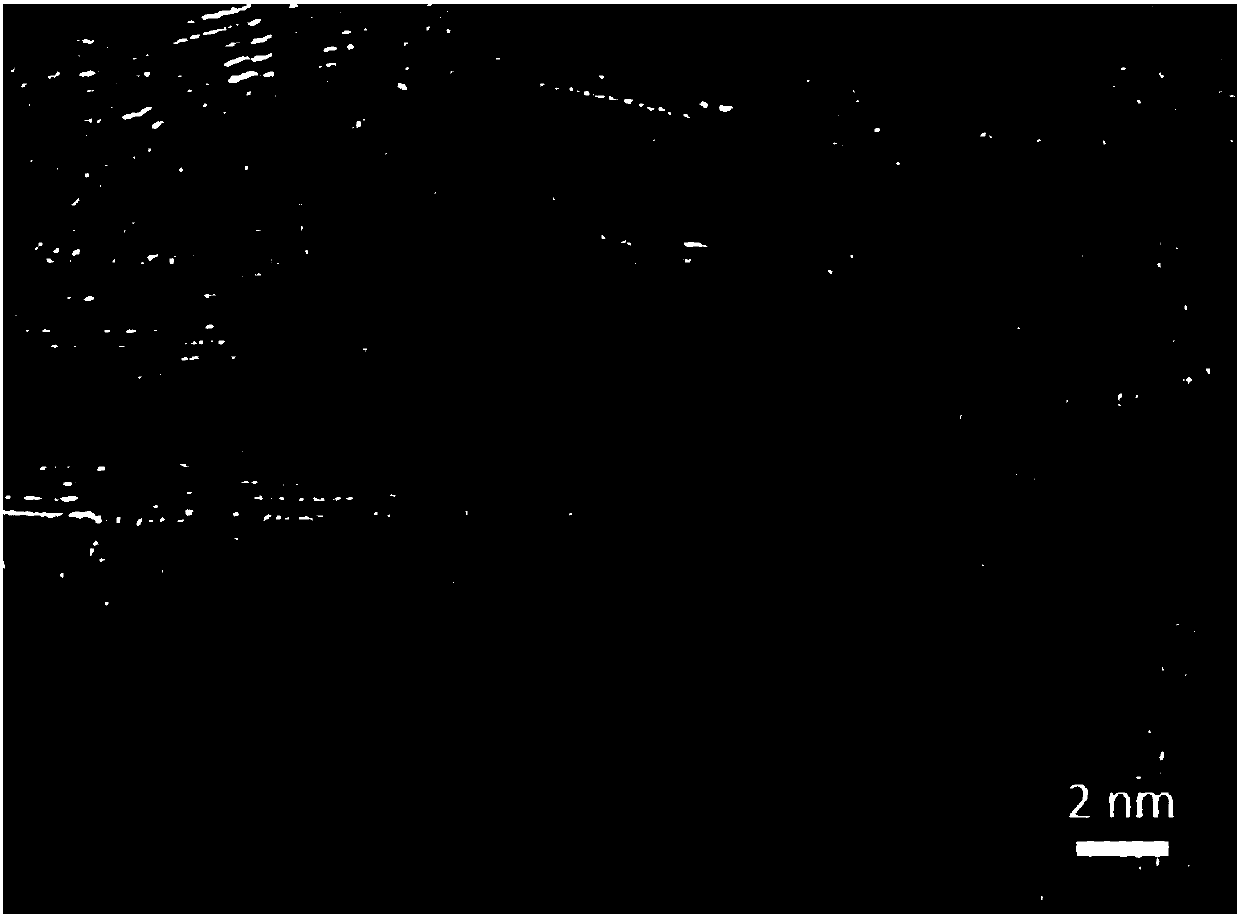

[0028] (2) Preparation of hexagonal boron nitride nanosheets: Place the boron precursor containing calcium ions in step (1) in a vacuum tube furnace, and heat up at a rate of 5°C / min in an ammonia gas atmosphere with a flow rate of 60ml / min. The temperature was raised from room temperature to 1400°C, kept for 3 hours, and then naturally cooled t...

Embodiment 2

[0031] A hexagonal boron nitride nanosheet with a controllable layer number is prepared by the following method:

[0032] (1) Preparation of boron precursors containing calcium ions: add 0.1mol boric acid and 0.4mol concentrated ammonia water (about 30ml) to 10ml deionized water successively, place them in a constant temperature water bath at 60°C for magnetic stirring, and then gradually add 10 ml of calcium nitrate solution with a concentration of 0.05 mol / L was added dropwise, stirred at constant temperature for 2 hours, and then placed in an oven at 110° C. for heat treatment for 6 hours to obtain a boron precursor containing calcium ions.

[0033] (2) Preparation of hexagonal boron nitride nanosheets: Place the boron precursor containing calcium ions in step (1) in a vacuum tube furnace, and heat up at a rate of 20°C / min in an ammonia gas atmosphere with a flow rate of 200ml / min. The temperature was raised from room temperature to 1350°C, kept for 1 hour, and then natural...

Embodiment 3

[0036] A hexagonal boron nitride nanosheet with a controllable layer number is prepared by the following method:

[0037] (1) Preparation of boron precursors containing calcium ions: add 0.1mol ammonium pentaborate and 0.4mol concentrated ammonia water (about 30ml) to 10ml of deionized water in sequence, place them in a constant temperature water bath at 70°C for magnetic stirring, and then add 10 ml of calcium chloride solution with a concentration of 0.1 mol / L was added dropwise, stirred at constant temperature for 1.5 h, and then placed in a 120°C oven for heat treatment for 12 h to obtain a boron precursor containing calcium ions.

[0038] (2) Preparation of hexagonal boron nitride nanosheets: Place the boron precursor containing calcium ions in step (1) in a vacuum tube furnace, and heat up at a rate of 10°C / min in an ammonia gas atmosphere with a flow rate of 100ml / min. The temperature was raised from room temperature to 1450°C, kept for 3 hours, and then naturally coole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com