Annular electrode electrolytic tank

A technology of ring electrodes and electrolytic tanks, applied in water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve equipment/or facility/or device manufacturing costs, high operating costs, and time-consuming Long, large footprint and other issues, to achieve the effect of promoting technological progress, convenient production, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

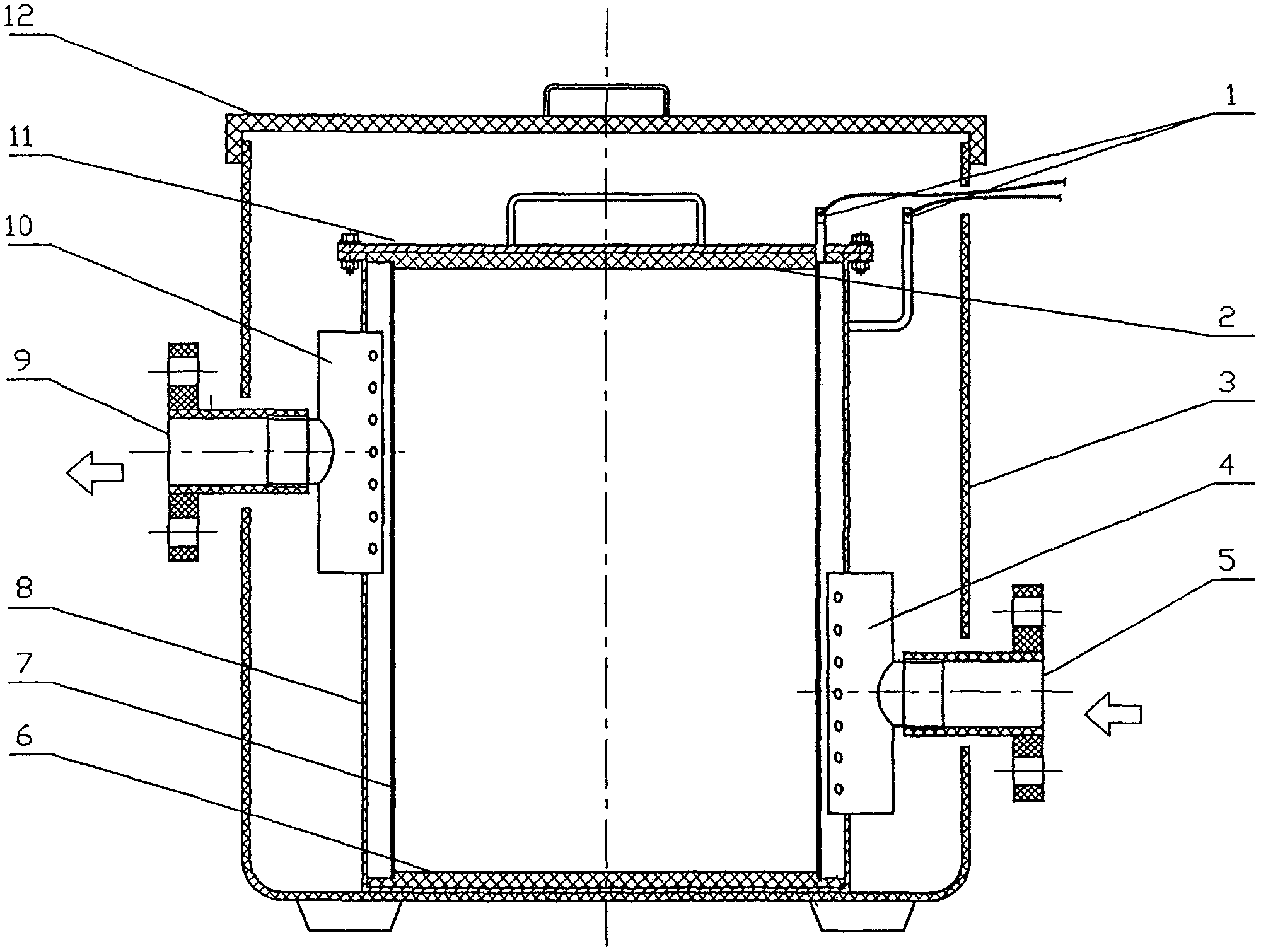

[0028] The ring electrode electrolytic tank of the present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the accompanying drawings:

[0029] A ring electrode electrolytic tank, comprising cathode and anode terminal 1, electrode upper limit plate 2, electrolytic tank outer barrel 3, water separator 4, water inlet 5, electrode lower limit plate 6, anode 7, cathode 8, water outlet 9 , a water collector 10, an electrode tank cover 11, and an electrolytic tank cover 12;

[0030] Described annular electrode electrolytic tank, the outer end of its cathode and anode terminal 1 and power line, the inner end of cathode of cathode and anode terminal 1 and cathode 8, the inner end of cathode and anode terminal 1 anode and anode 7, one of cathode 8 Side and water separator 4, water separator 4 and water inlet 5, water inlet 5 and one side of electrolytic tank outer barrel 3, the other side of cathode 8 and water collector 10, water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com