Quartz glass annealing furnace

A technology of quartz glass and annealing furnace, applied in the field of quartz glass annealing furnace, which can solve the problems of low annealing efficiency, inconvenient use, long annealing cycle, etc., and achieve the effects of short annealing time, high processing efficiency and fast heating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

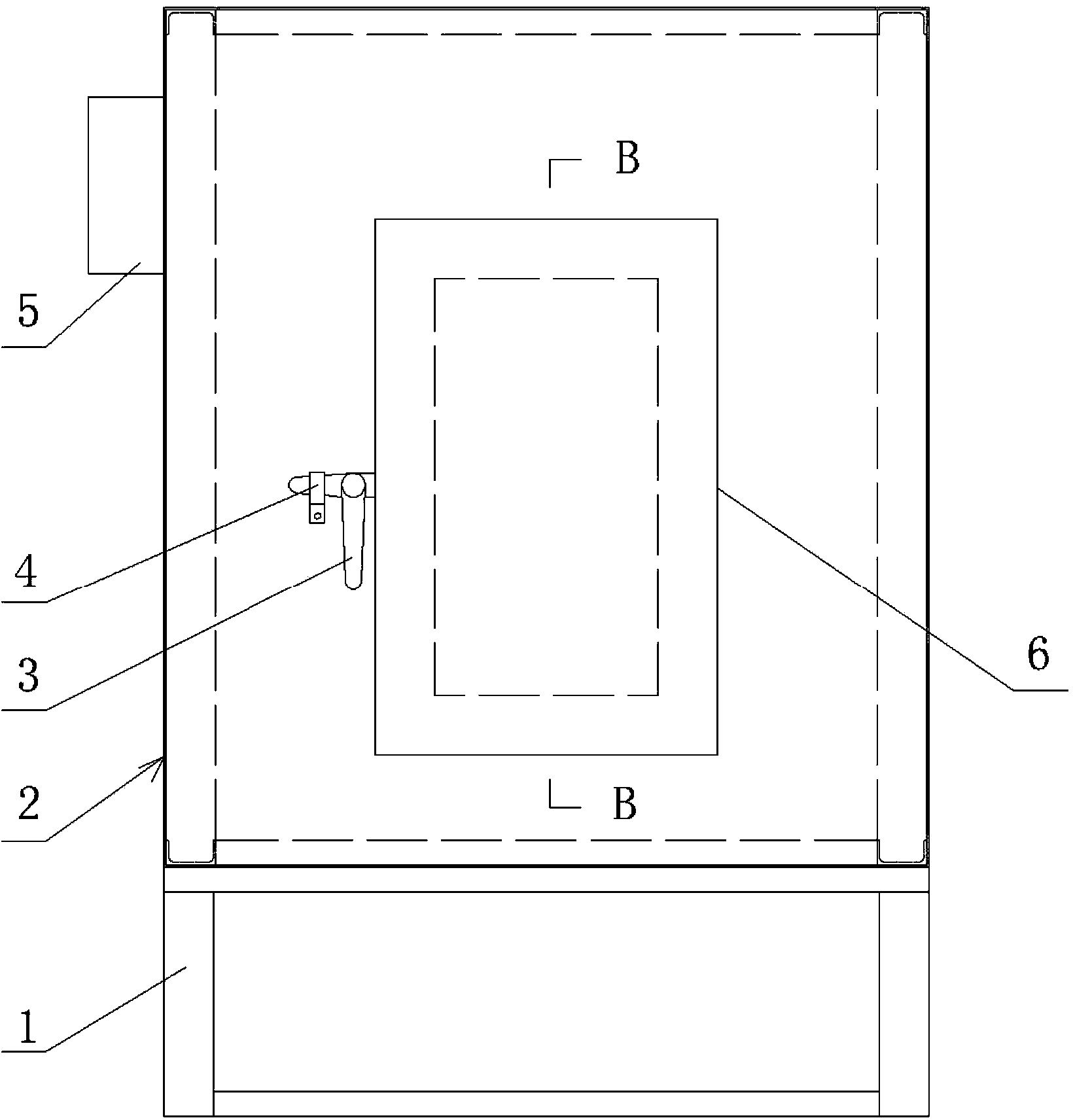

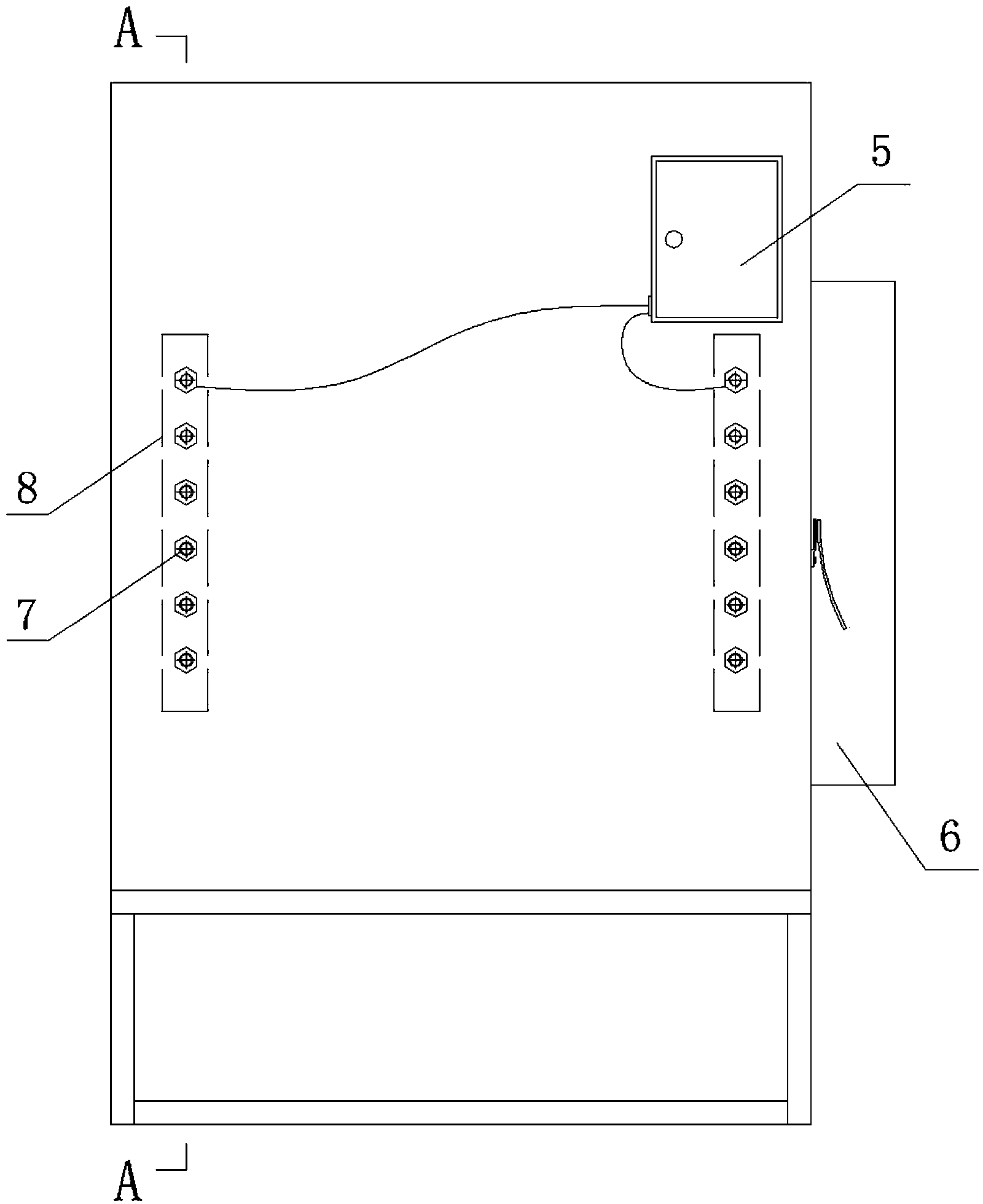

[0025] Such as figure 1 with figure 2 As shown, the quartz glass annealing furnace includes a furnace body 2, and the furnace body 2 is composed of a frame 12 welded by channel steel and an outer guard plate 11 fixedly surrounding the outer surface of the frame 12. A furnace 9 is provided in the middle of the furnace body 2, and a furnace door 6 for closing the furnace 9 is hinged in front of the furnace body 2, and a lock door handle 3 is hinged on the free end side of the furnace door 6, corresponding to the lock in front of the furnace body 2. The door handle 3 is fixed with a door lock clamping plate 4 .

[0026] Such as Figure 4 As shown, in the furnace body 2, located on both sides of the furnace 9 and behind it, from the inside to the outside, are the furnace inner layer 16, the insulation cotton layer 15, the insulation brick layer 14 and the perlite layer 17, and the furnace body 2 is located below the furnace 9 in sequence. Be furnace bottom 19, insulation brick...

Embodiment 2

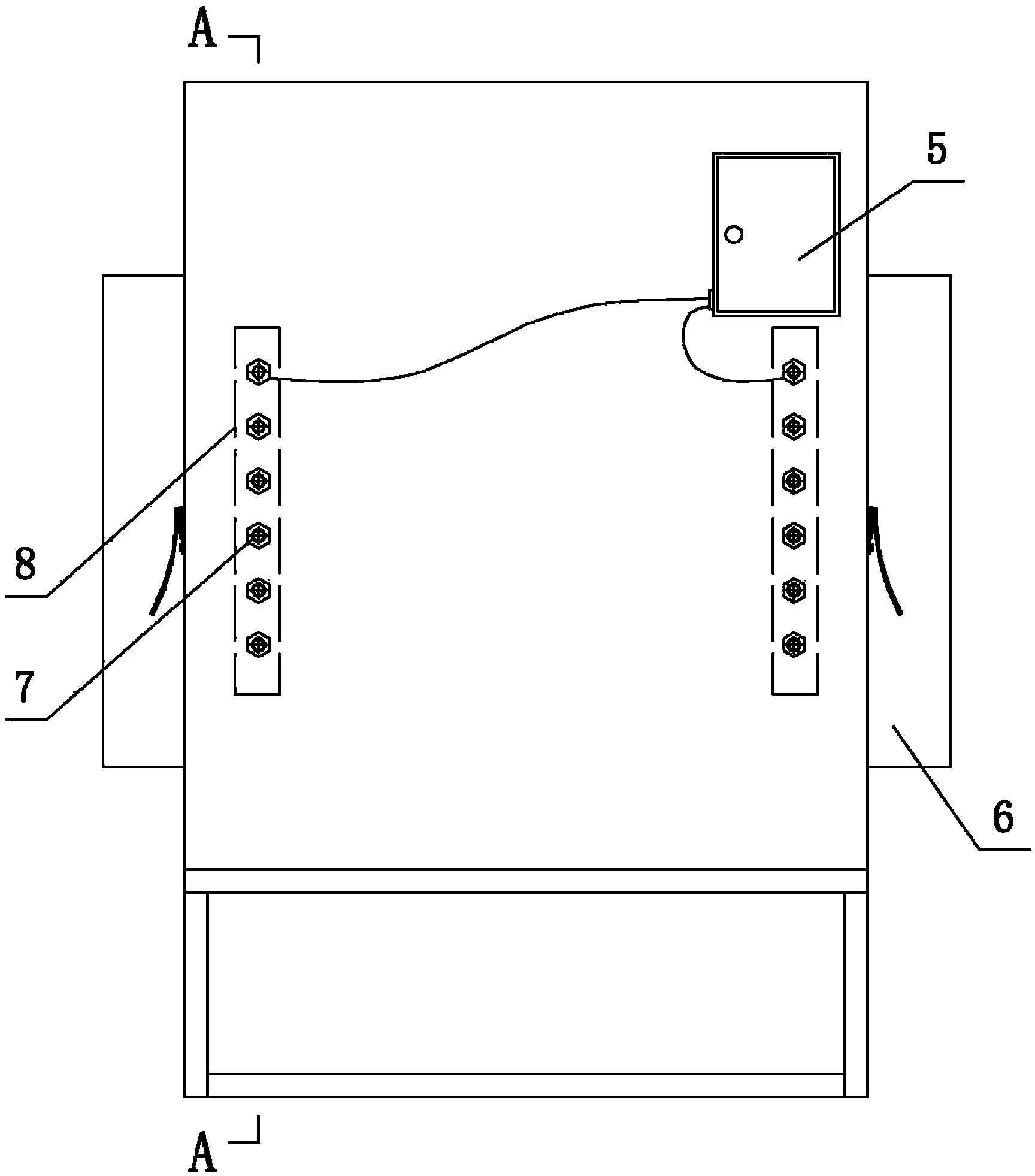

[0033] Such as figure 1 with image 3 As shown, the quartz glass annealing furnace includes a furnace body 2, the furnace body 2 is composed of a frame 12 welded by channel steel and an outer guard plate 11 fixedly surrounding the outer surface of the frame 12. A hearth 9 is provided in the middle of the body of furnace 2, and the hearth 9 runs through the body of furnace 2. A furnace door 6 for closing the hearth 9 is respectively hinged at the front and rear of the body of furnace 2, and a furnace door 6 is hinged on the free end side of the furnace door 6. The door lock handle 3 is respectively fixed with a door lock clamping plate 4 at the corresponding lock door handle 3 places before and after the furnace body 2 .

[0034] Such as Figure 4 As shown, in the furnace body 2, located on both sides of the furnace 9 from the inside to the outside are the inner layer 16 of the furnace, the insulation cotton layer 15, the insulation brick layer 14 and the perlite layer 17, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com