Efficient artificial algal reef using tidal flat mud as raw material and preparation method of efficient artificial algal reef

A technology of silt and algae reef, which is applied in the field of high-efficiency artificial algae reef and its preparation, can solve the problems that mud flat mud is rarely involved, and achieve the effects of improving compatibility, reducing usage, and reducing alkalinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The proliferation of artificial algae farms requires a large amount of artificial algae reefs as the attachment substrate for algae and their spores, and a good nutrient saline water environment is conducive to the survival and growth of algae and their spores, speeding up the proliferation of artificial algae farms and improving the quality of reef investment. Ocean primary productivity in sea areas.

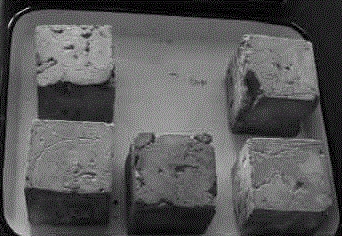

[0021] In January 2013, mud flat sediment was collected in Shuangdao Bay, Weihai City, Shandong Province, and an experiment on the dissolution effect of nutrients in high-efficiency artificial algal reefs using mud flat mud as raw material was carried out. According to the proportion of silt and cement, there are four levels: 0.3:1, 0.5:1, 0.7:1, 0.9:1. According to the specifications of 70.7mm×70.7mm×70.7mm, reefs with different levels of silt were made respectively. After they were fully dried and hardened, they were put into a 1000mL beaker, filled with 700mL of seawa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com