Low-loss ferrite material

A ferrite material and low-loss technology, applied in the field of magnetic core materials, can solve the problem of unsatisfactory comprehensive performance of ferrite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

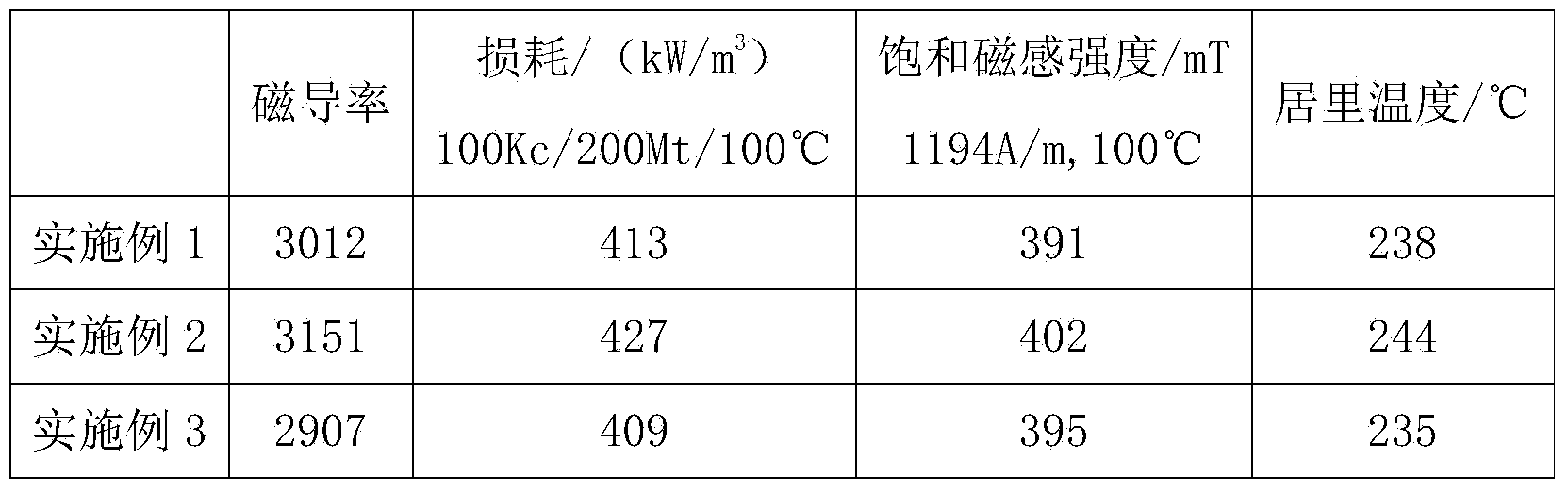

Examples

Embodiment 1

[0017] A low-loss ferrite material, each raw material is weighed according to the following ratio: Fe 2 o 3 , MnO, ZnO, sodium pyrophosphate, CaO, SiO 2 , V 2 o 5 、MoO 3 、 Bi 2 o 3 ,P 2 o 5 , where Fe 2 o 3 :MnO:ZnO molar ratio is 54:34:12, with Fe 2 o 3 , MnO, ZnO three quality and as the basis, sodium pyrophosphate, CaO, SiO 2 , V 2 o 5 、MoO 3 、 Bi 2 o 3 ,P 2 o 5 The mass fractions are 1.1%, 0.032%, 0.006%, 0.020%, 0.017%, 0.026%, 0.023%, respectively;

[0018] According to the above-mentioned raw material formula, the low-loss ferrite material is prepared according to the following steps:

[0019] S1: a ball mill: the Fe 2 o 3 , MnO, ZnO, CaO, SiO 2 , V 2 o 5 、MoO 3 、 Bi 2 o 3 ,P 2 o 5 Put it into a ball mill, adopt a rotating speed of 450r / min, carry out mixed ball milling, dry after ball milling for 3.5 hours, and set aside;

[0020] S2: Pre-burning: put the ball-milled powder in S1 into the holding furnace, raise the temperature to 895°C at...

Embodiment 2

[0024] A low-loss ferrite material, each raw material is weighed according to the following ratio: Fe 2 o 3 , MnO, ZnO, sodium pyrophosphate, CaO, SiO 2 , V 2 o 5 、MoO 3 、 Bi 2 o 3 ,P 2 o 5 , where Fe 2 o 3:MnO:ZnO molar ratio is 54.5:34:11.5, with Fe 2 o 3 , MnO, ZnO three quality and as the basis, sodium pyrophosphate, CaO, SiO 2 , V 2 o 5 、MoO 3 、 Bi 2 o 3 ,P 2 o 5 The mass fractions are 1.0%, 0.030%, 0.005%, 0.020%, 0.015%, 0.025%, 0.025%, respectively;

[0025] According to the above-mentioned raw material formula, the low-loss ferrite material is prepared according to the following steps:

[0026] S1: a ball mill: the Fe 2 o 3 , MnO, ZnO, CaO, SiO 2 , V 2 o 5 、MoO 3 、 Bi 2 o 3 ,P 2 o 5 Put into the ball mill, adopt the rotating speed of 460r / min, carry out mixed ball mill, dry after ball mill 3h, stand-by;

[0027] S2: Pre-burning: put the ball-milled powder in S1 into the holding furnace, raise the temperature to 880°C at an average heatin...

Embodiment 3

[0031] A low-loss ferrite material, each raw material is weighed according to the following ratio: Fe 2 o 3 , MnO, ZnO, sodium pyrophosphate, CaO, SiO 2 , V 2 o 5 、MoO 3 、 Bi 2 o 3 ,P 2 o 5 , where Fe 2 o 3 :MnO:ZnO molar ratio is 53.5:35:11.5, with Fe 2 o 3 , MnO, ZnO three quality and as the basis, sodium pyrophosphate, CaO, SiO 2 , V 2 o 5 、MoO 3 、 Bi 2 o 3 ,P 2 o 5 The mass fractions are 1.5%, 0.033%, 0.008%, 0.018%, 0.011%, 0.021%, 0.029%, respectively;

[0032] According to the above-mentioned raw material formula, the low-loss ferrite material is prepared according to the following steps:

[0033] S1: a ball mill: the Fe 2 o 3 , MnO, ZnO, CaO, SiO 2 , V 2 o 5 、MoO 3 、 Bi 2 o 3 ,P 2 o 5 Put into the ball mill, adopt the rotating speed of 440r / min, carry out mixing ball mill, dry after ball milling 4h, stand-by;

[0034] S2: Pre-burning: put the ball-milled powder in S1 into the holding furnace, raise the temperature to 905°C at an average h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com