The synthetic technique of meclofenoxate hydrochloride crude product

A technology of meclofenoxate hydrochloride and synthesis process, which is applied in the preparation of organic compounds, preparation of aminohydroxyl compounds, organic chemistry, etc., can solve the problems such as the unreported synthesis method of crude meclofenoxate hydrochloride, and achieve the reduction of production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] Example: Synthesis of crude meclofen axetil hydrochloride (calculated in batch 47kg).

[0029] (10) Before starting production, check that the equipment and workplace have no products, documents or materials unrelated to the production of this batch of products left over from the previous batch, and the equipment is in a clean and ready-to-use state; Valves, measuring instruments, monitoring instruments and auxiliary equipment are in good condition;

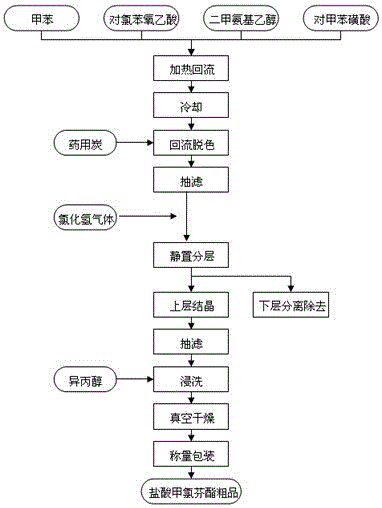

[0030] (20) synthesis reaction, its concrete steps include: heating to reflux, cooling, reflux decolorization, suction filtration and standing for stratification;

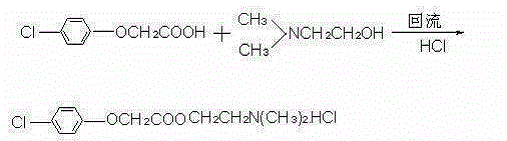

[0031] (21) heating to reflux: open the vacuum of the reaction tank, pump 181kg of toluene into the first reaction tank of 500L, open stirring, pump 24.7kg of dimethylaminoethanol, open the feeding port of the first reaction tank, drop into p-chlorophenoxyacetic acid 39.5kg, 1.2kg of p-toluenesulfonic acid, open the first reaction tank jacket steam, stir to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com