Poly1-butylene nucleating agent composition and application thereof

A technology of nucleating agent and composition, which is applied in the field of poly-1-butene nucleating agent composition, can solve the problems of less research on poly-1-butene nucleating agent, etc., and achieve shortened production cycle, less by-products, and crystallization speed Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

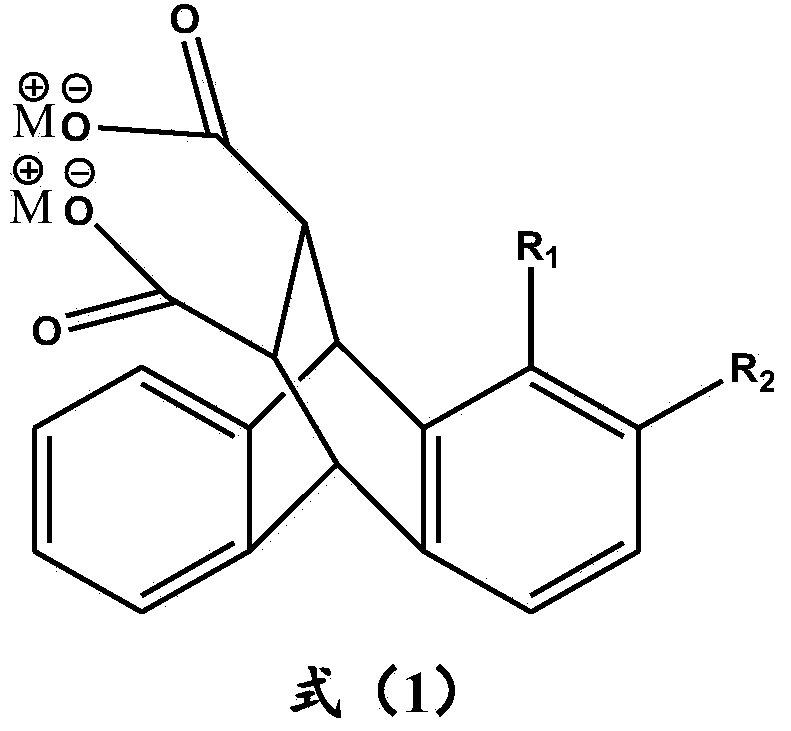

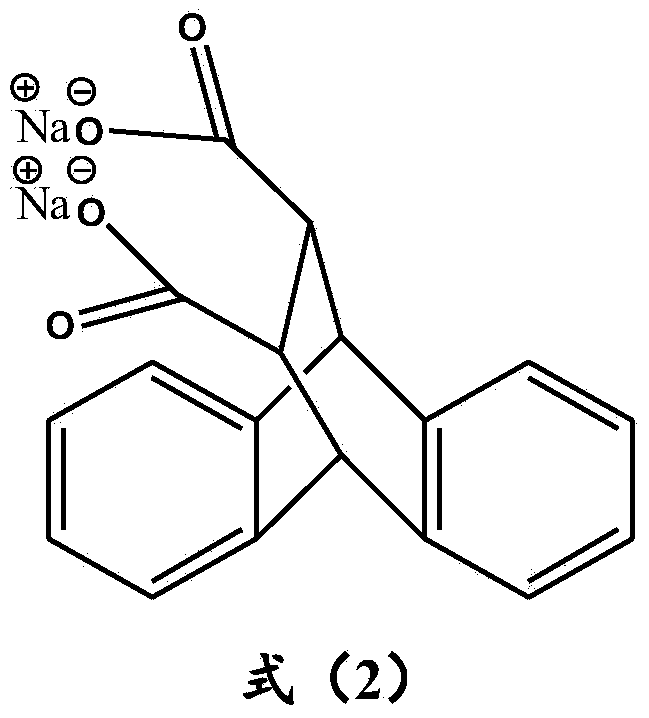

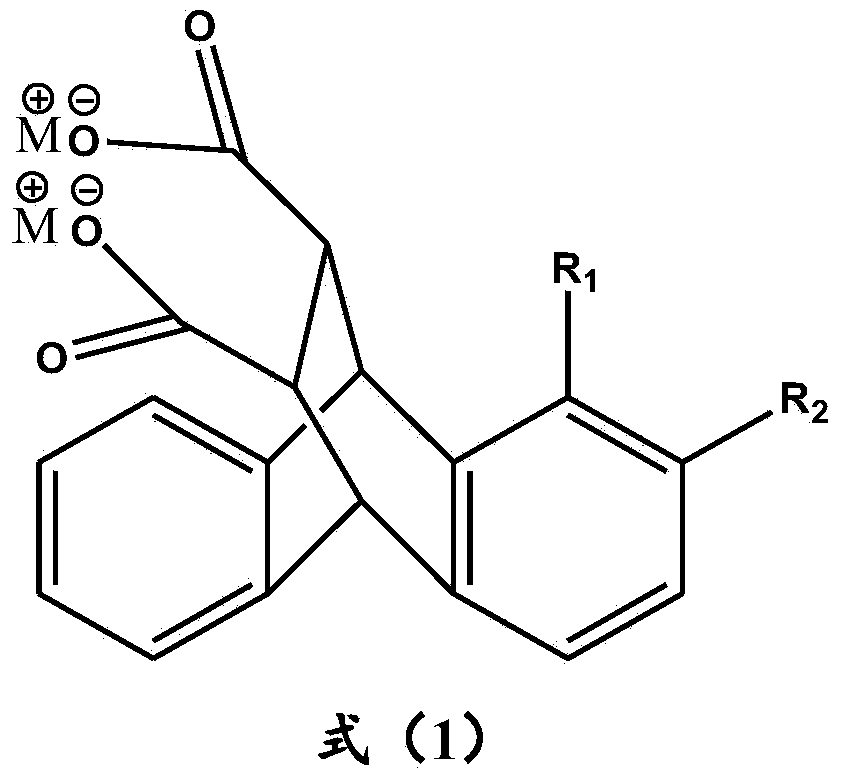

[0067] Embodiment 1: the synthesis of nucleating agent

[0068] (a) Synthesis of 9,10-dihydro-9,10-ethylene-anthracene-11,12-dianhydride

[0069] Get 20g (112mmol) anthracene and dissolve in 250ml dichloromethane, at 0 o C divides and adds the anhydrous aluminum chloride of 16.5g (124mmol) several times, then at 0 o Under the condition of C, 11 g (112 mmol) of maleic anhydride was added to the above reaction vessel several times, and stirred overnight at room temperature. The solvent was poured into 350 ml of deionized water, the organic phase was separated, and the aqueous phase was extracted with dichloro. The organic phases were poured together, then washed with deionized water, dried with anhydrous magnesium sulfate, filtered, and the solvent was rotary evaporated, and dried to obtain the desired product.

[0070] 1 H NMR (400MHZ, CDCl 3 )δ7.32 (dd, 2H) 7.28 (dd, 2H), 7.15 (m, 4H) 4.65 (s, 2H), 3.52 (s, 2H)

[0071] (b) Synthesis of 9,10-dihydro-9,10-ethylene-anthrac...

Embodiment 2

[0074] Embodiment 2: Preparation of nucleating agent composition

[0075] The nucleating agent 9,10-dihydro-9,10-ethylene-anthracene-11,12-dioic acid sodium salt in Example 1 was vacuum-dried at 80°C overnight, and then dried at 110°C for 2 hours. The caking agent silica gel (nucleating agent 90wt%) was co-ground, and its particle size was measured.

Embodiment 3

[0076] Embodiment 3: Preparation and determination of poly-1-butene sample

[0077] Add 4ml of white oil to 1kg of poly-1-butene pure material masterbatch, stir well to make a layer of white oil evenly attached to the poly-1-butene particles, and then add the treated 9,10-dihydro-9,10 -Ethylene-anthracene-11,12-dioic acid sodium salt nucleating agent and anti-caking agent silica gel mixture 1g (1000ppm based on the nucleating agent contained therein) fully shake

[0078] uniform. It is extruded on a large screw machine, and then injected into a sample, and its various properties are measured.

[0079] According to the formula ratio in Table 1, the nucleating agent and poly-1-butene were evenly mixed, extruded and pelletized with a twin-screw extruder, and then injection molded into a standard sample. The temperature range of the twin-screw extruder is 175°C-210°C, and the rotation speed is 180r / min. The screw temperature of the injection molding machine is 205°C, the mold t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com