Adhesive applicable to low temperature and used for electronic paper, and preparation method and application thereof

A technology of electronic paper and adhesives, applied in the direction of adhesives, non-polymer adhesive additives, adhesive types, etc., can solve problems such as obstacles to the application of electrophoretic display devices, affect the display performance of electrophoretic display devices, and reduce the glass transition temperature , the resistivity will not rise sharply, and the effect of improving adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

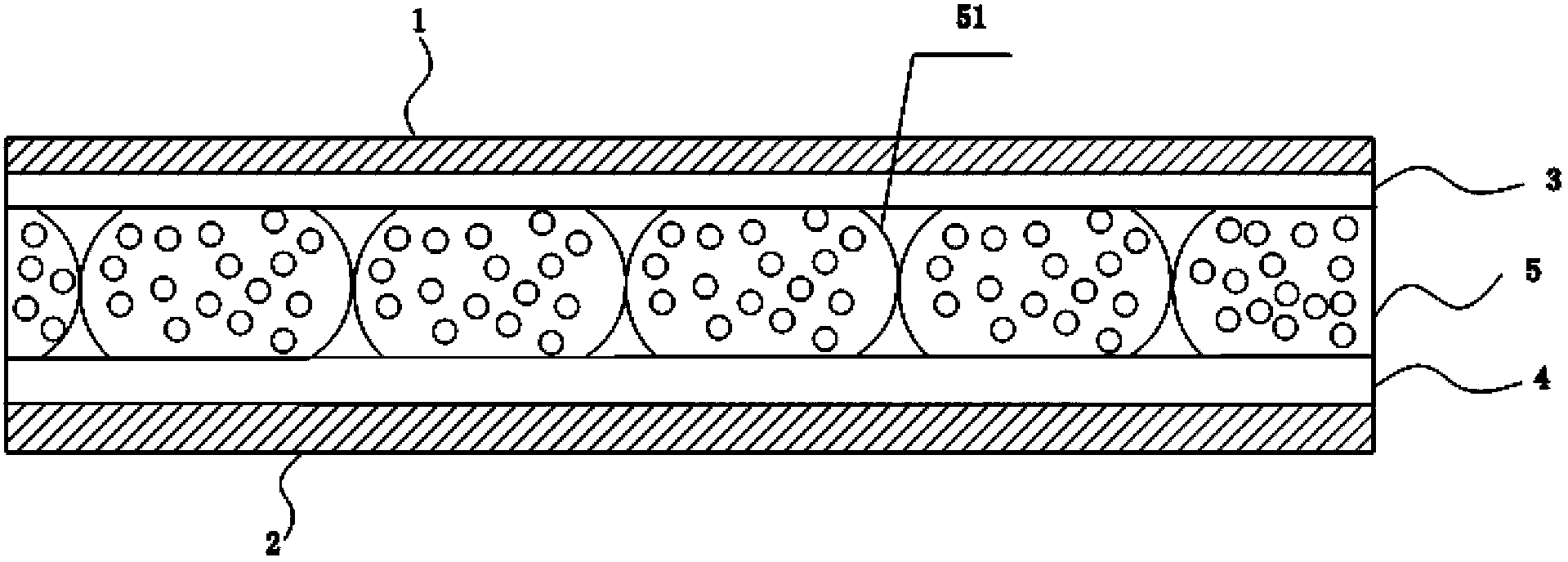

Image

Examples

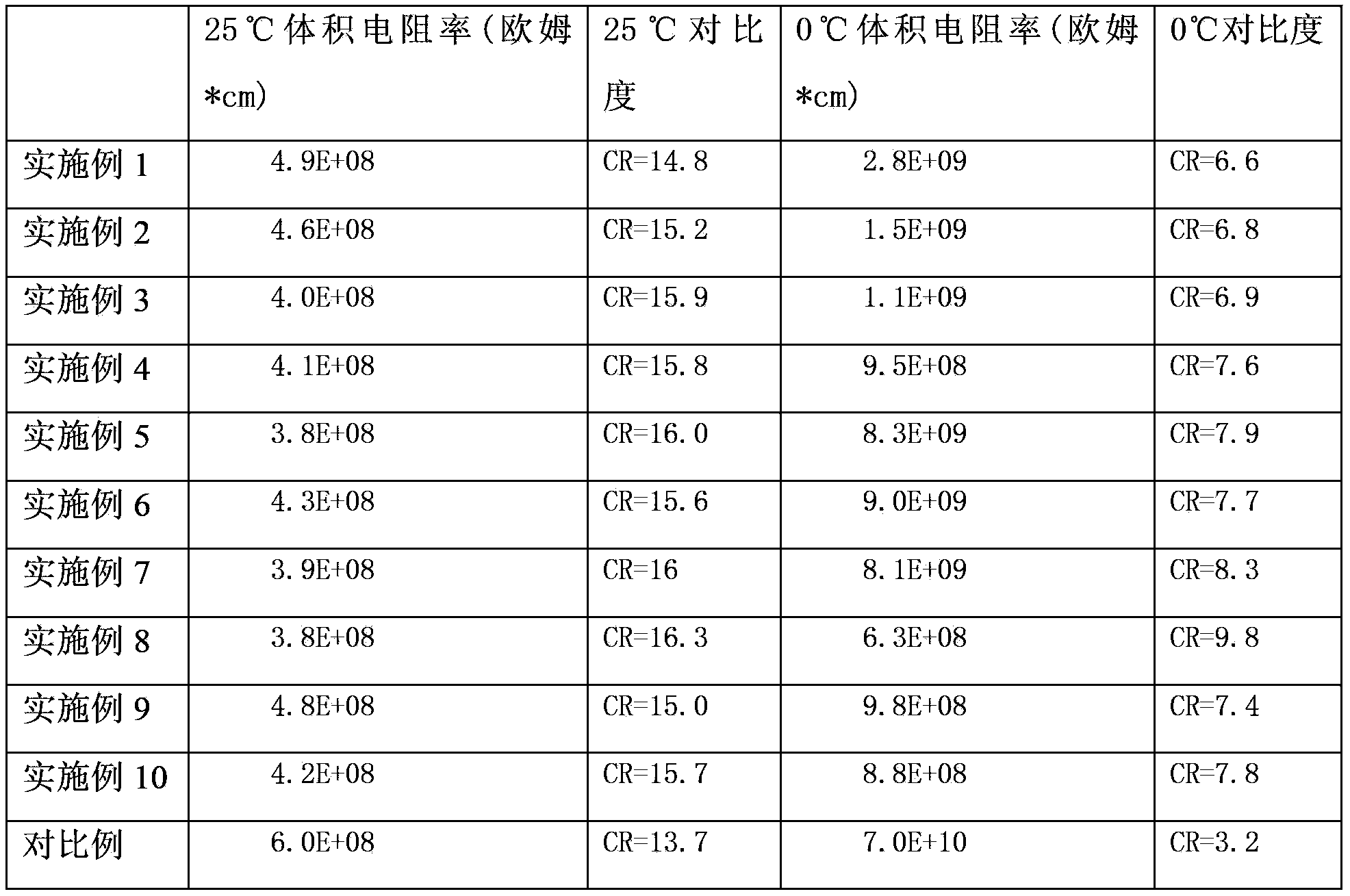

Embodiment 1

[0032] Embodiment 1 (without adding aniline group-containing compound and water-soluble conductive inorganic filler)

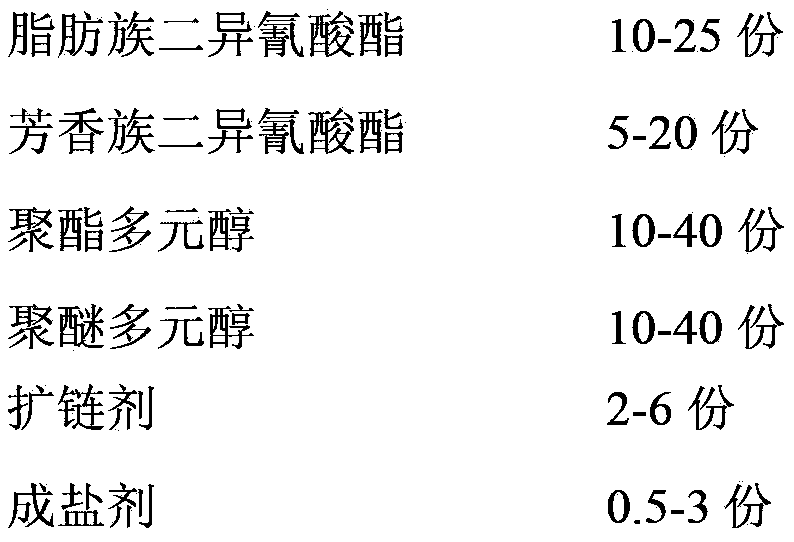

[0033] 10 parts by weight of aliphatic diisocyanate, 5 parts by weight of aromatic diisocyanate, 10 parts by weight of polyester diol (number average molecular weight 300), 10 parts by weight of polyether diol (number average molecular weight 400), 2 parts by weight of hydrophilic group glycol chain extender, put into the reaction pot at 70°C and stir for 2 hours, the measured NCO% content is 0.5wt%, add acetone according to the mass ratio of 1.3:2 (reaction mixture), lower the temperature Stir until completely dissolved at 40°C, add 1 part by weight of salt-forming agent, stir for 0.5 hours, add deionized water to the mixture at a mass ratio of 1.2 (mixture):1, disperse and emulsify into a water-based adhesive in a high-speed disperser. After dispersing for 1 hour, the acetone was removed in vacuum, and the solid content of the prepared aqueous polyurethane w...

Embodiment 2

[0034] Embodiment 2 (without adding compounds containing aniline groups and water-soluble conductive inorganic fillers)

[0035] 25 parts by weight of aliphatic diisocyanate, 20 parts by weight of aromatic diisocyanate, 40 parts by weight of polyester diol (number average molecular weight 3000), 40 parts by weight of polyether diol (number average molecular weight 3000), 6 parts by weight of a hydrophilic group diol chain extender was put into the reaction pot at 90°C and stirred for 5 hours. The NCO% content was measured to be 6wt%. Add acetone at a mass ratio of 1.3:2 (reaction mixture) and lower the temperature to Stir until completely dissolved at 58°C, add 3 parts by weight of salt-forming agent, stir for 0.5 hours, add deionized water to the mixture at a mass ratio of 1.2 (mixture):1, and disperse and emulsify it into a water-based adhesive in a high-speed disperser. After dispersing for 1 hour, the acetone was removed in vacuum, and the solid content of the prepared aqu...

Embodiment 3

[0036] Embodiment 3 (adding the compound containing aniline group, but not adding water-soluble conductive inorganic filler)

[0037] 10 parts by weight of aliphatic diisocyanate, 5 parts by weight of aromatic diisocyanate, 10 parts by weight of polyester diol (number average molecular weight 300), 10 parts by weight of polyether diol (number average molecular weight 400), 2 parts by weight of hydrophilic group glycol chain extender, put into the reaction pot at 70°C and stir for 2 hours, the measured NCO% content is 0.5wt%, depending on the viscosity, add acetone according to the mass ratio of 1.3:2 (reaction mixture), Lower the temperature to 40°C, stir until completely dissolved, drop 2 parts by weight of the compound containing aniline groups within 0.5 hours, stir for 0.5 hours, add 1 part by weight of a salt-forming agent, stir for 0.5 hours, and mix the mixture according to the mass ratio 1.2 (mixture): 1, add deionized water, disperse and emulsify into a water-based ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com