Efficient and short-process multi-component melt spinning device

A technology of melt spinning and short process, which is applied in melt spinning, complete sets of equipment for producing artificial threads, textiles and papermaking, etc. It can solve problems such as uncontrollable composite fiber structure, interface separation, and decline in mechanical properties of composite fibers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

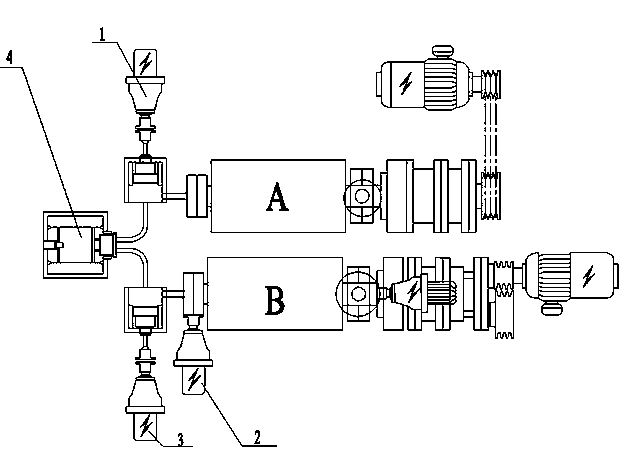

[0014] Combine below figure 1 A high-efficiency, short-flow multi-component melt spinning equipment of the present invention is further described in detail.

[0015] Such as figure 1 as shown,

[0016] A high-efficiency, short-flow multi-component melt-spinning equipment, the melt-spinning machine is composed of a single-screw extruder A and a twin-screw extruder. A first metering pump 1 is arranged at the head of the single-screw extruder A, a booster pump 2 is arranged at the head of the twin-screw extruder B, and the booster pump 2 is connected to the second metering pump 3 through a pipeline. The first metering pump 1 and the second metering pump 3 are respectively connected to the spinning assembly 4 through independent pipelines.

[0017] Working principle of the present invention:

[0018] 1. When extruding single-component round fibers, close the twin-screw mixing extruder B and its booster pump 2 and the second metering pump 3 device, open the single-scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com