Repair process of heat distribution pipeline

A thermal pipeline and process technology, applied in the direction of thermal insulation protection pipeline, pipeline protection, heat exchange equipment, etc., can solve the problems of affecting the service life of the thermal insulation layer, the complex ratio of thermal insulation slurry, and cumbersome repair process steps, etc., to achieve flow Good performance, high strength and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

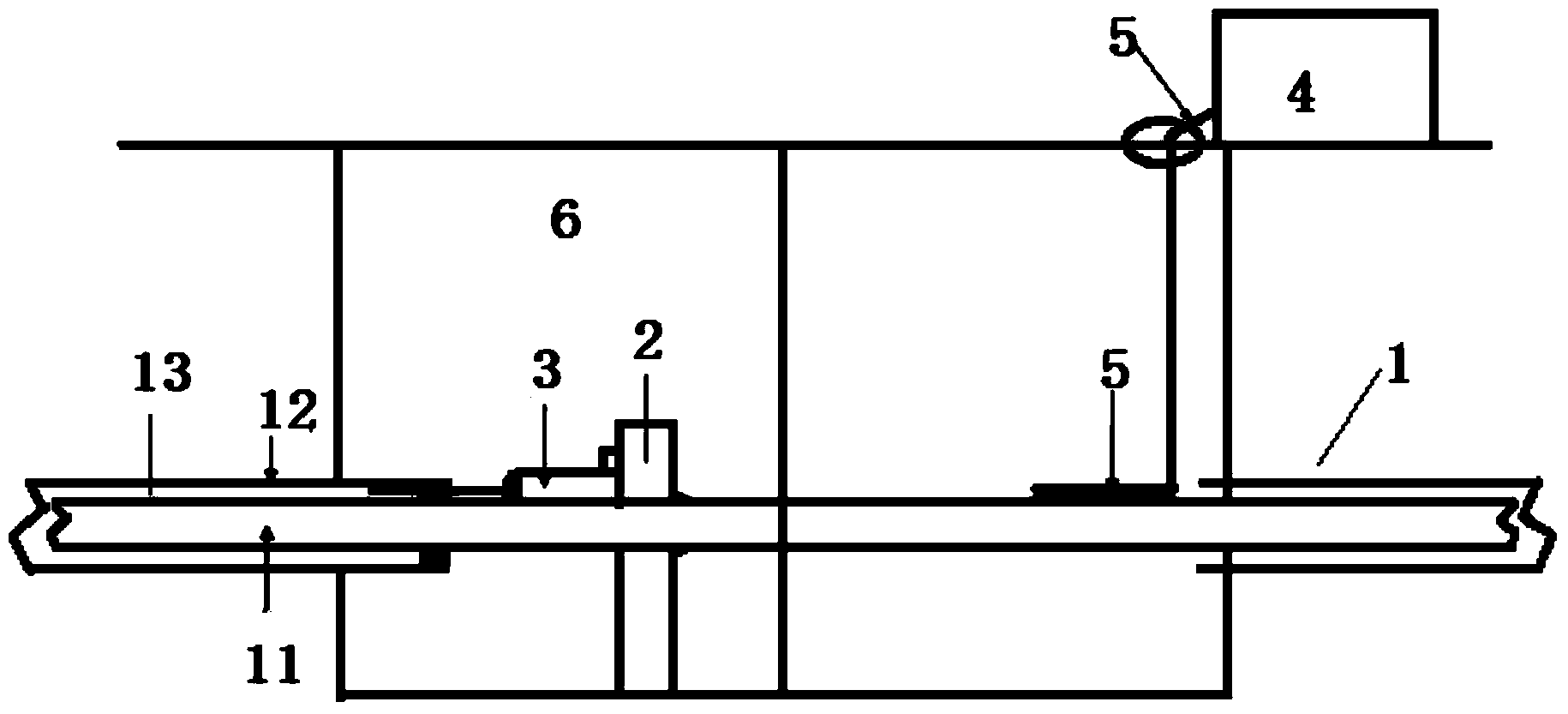

[0040] like figure 1 and figure 2 As shown, this embodiment provides a thermal pipeline repair process, which specifically includes the following steps:

[0041] A: Determine the construction fixed point 2 for installing the pressure device 3, which can be a jack;

[0042] B: Press the grouting pipe 5 connected to the grouting equipment 4 into the grouting hole through the pressure device 3, the grouting pipe 5 is pressed into the grouting hole by static force, the grouting The grouting pipe 5 adopts the flower pipe commonly used in the prior art. If the length of the grouting pipe 5 is not enough, it can be welded or screwed. The depth of the grouting pipe 5 pressed into the grouting hole is determined according to the resistance on the spot;

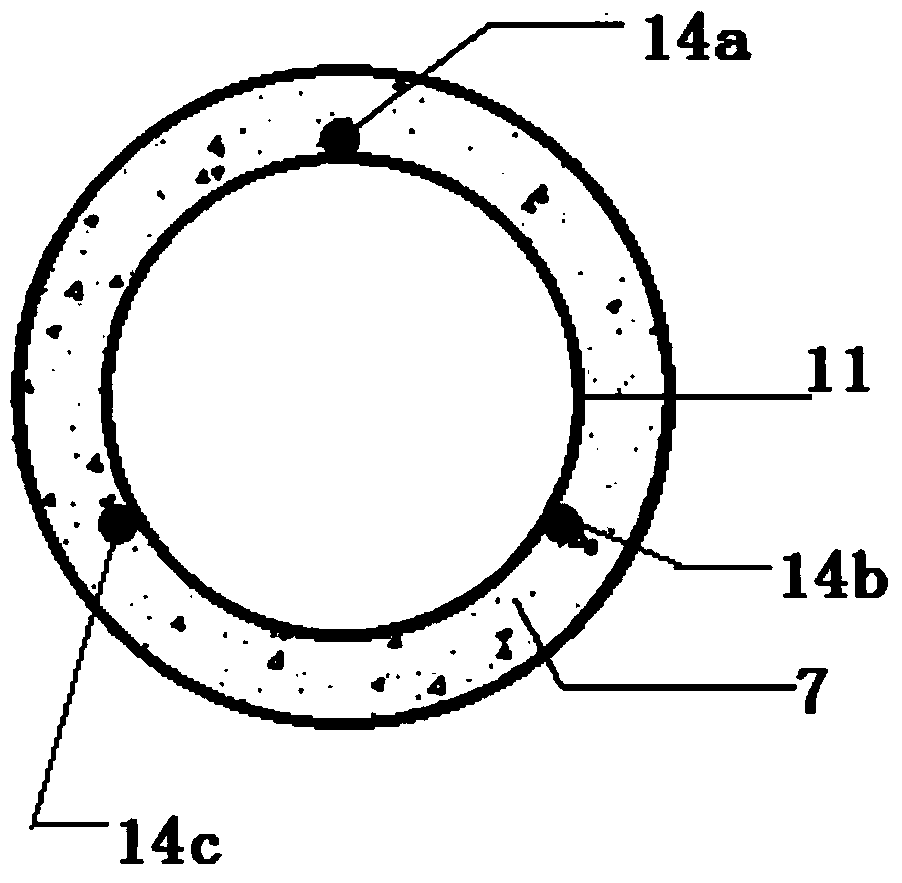

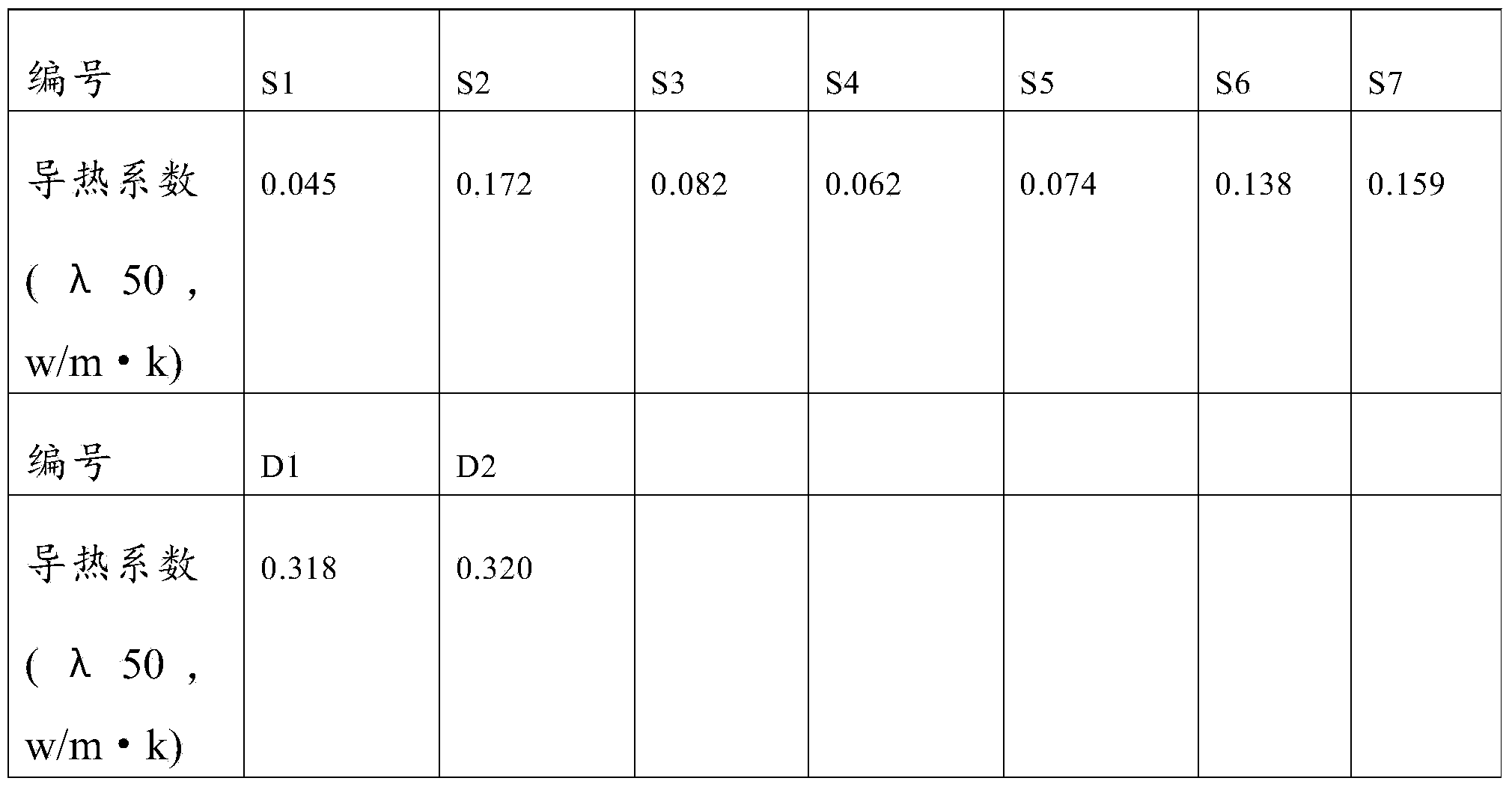

[0043] C: Inject thermal insulation slurry directly between the inner delivery pipe 11 and the outer shell 12 of the thermal pipeline 1 through the grouting hole, the grouting flow rate is 5L / min, and the grouting pressure is 2Mpa. ...

Embodiment 2

[0054] This embodiment provides a repair process for thermal pipelines, which is a modification based on Embodiment 1. In this embodiment, the formulation, grouting pressure, and grouting flow rate of the thermal insulation slurry are different from those in Embodiment 1. . Specifically, in this embodiment, the thermal insulation slurry includes: 90g of CGM grouting material (the grouting material of Shandong Tuoda Building Materials Co., Ltd., whose model is CGM380), 10g of silica airgel, and 20g of water. The silica airgel is a silica airgel powder with a particle size of 100 meshes, and the heat-insulating slurry made from the above formula is directly supplied to the inner delivery pipe 11 and the outer shell 12 of the thermal pipeline 1 through the grouting hole. During grouting, the grouting flow rate is 8L / min, and the grouting pressure is 4Mpa.

Embodiment 3

[0056] This embodiment provides a repair process for thermal pipelines, which is a modification based on Embodiment 1 and Embodiment 2. In this embodiment, the formula, grouting pressure, and grouting flow rate of the thermal insulation slurry are the same Examples are all different. Specifically, in this embodiment, the thermal insulation slurry includes: 99g of CGM grouting material (the grouting material of Shandong Tuoda Building Materials Co., Ltd., whose model is CGM380), 1g of silica airgel, and 30g of water. Silica airgel is silica airgel powder with a particle size of 150 meshes, and the thermal insulation slurry made from the above formula is directly injected between the inner delivery pipe 11 and the outer shell 12 of the thermal pipeline 1 through the grouting hole , the grouting flow rate is 10L / min, and the grouting pressure is 6Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com