Method for achieving motion control multi-branch synchronous execution based on teaching instructions

A motion control and multi-branch technology, applied in the direction of digital control, electrical program control, etc., can solve the problems of inability to achieve processing effects, economic benefits, and processing efficiency, and achieve stable and reliable work performance, save labor costs, and improve processing. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0096] A kind of specific implementation mode of the present invention can be carried out according to the following steps:

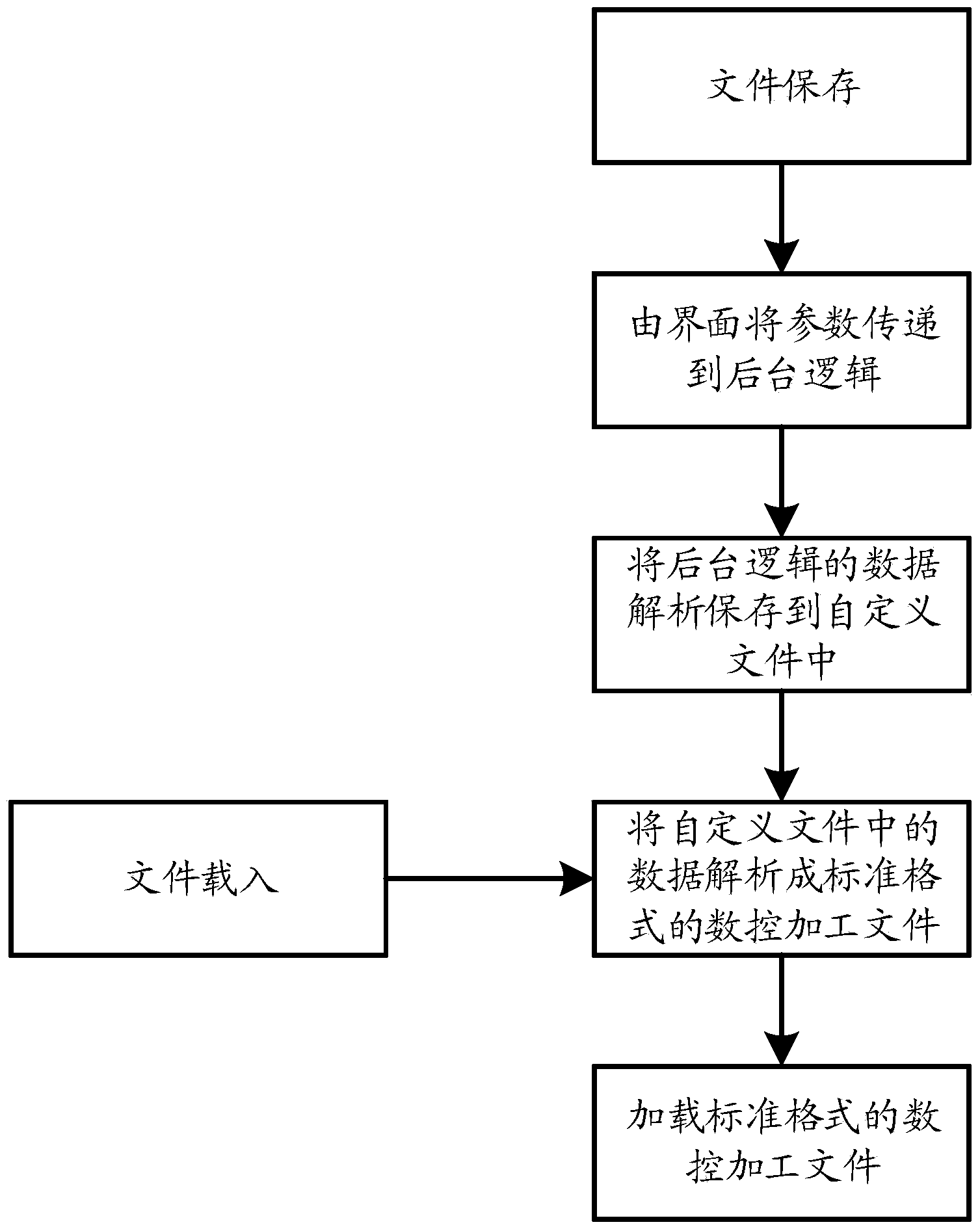

[0097] (1) Teach a set of teaching instructions through the control system, and save the taught instruction set in the control system in the form of a subroutine. At this time, the subroutine is saved in the hard disk in a specific data format.

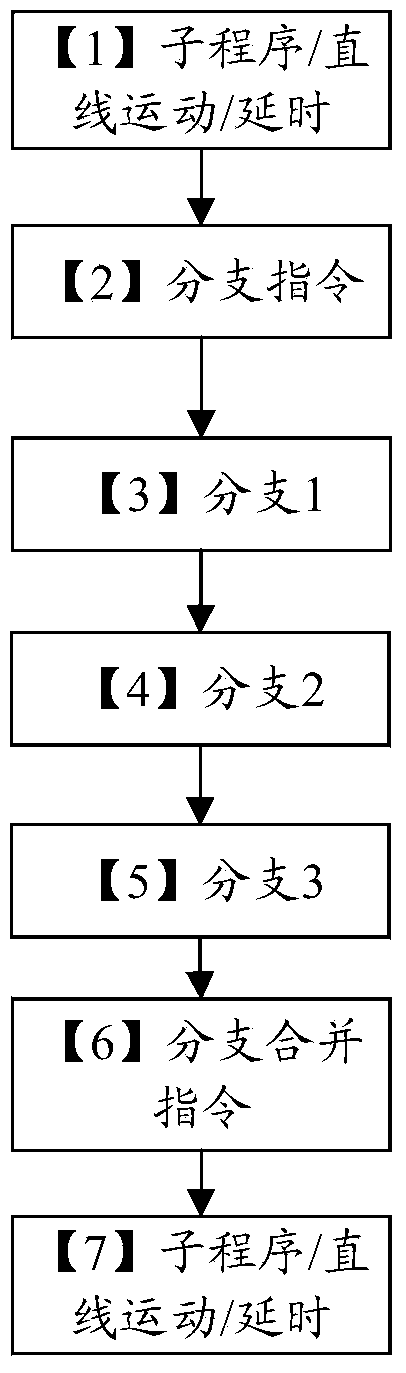

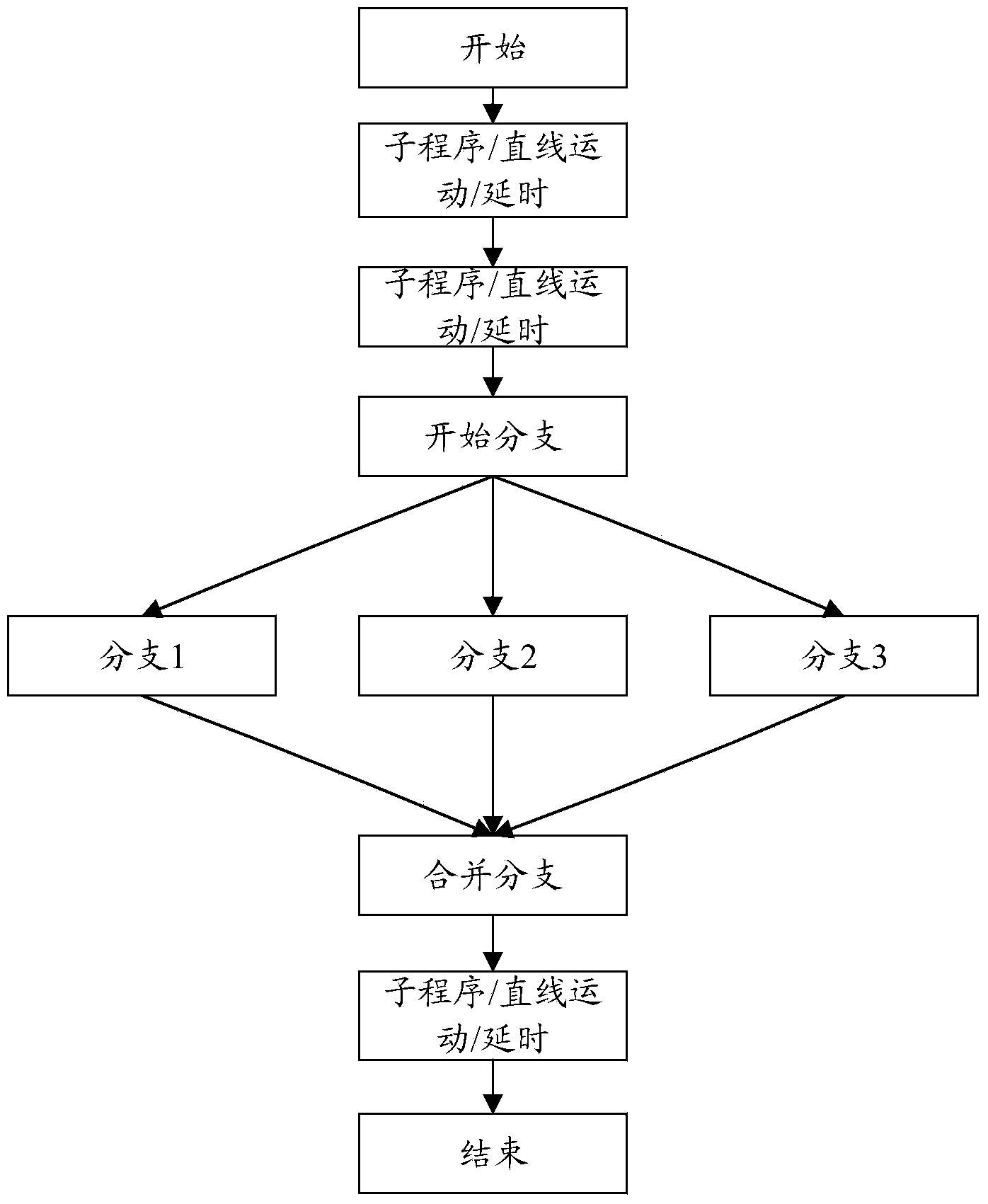

[0098] (2) A main program file is taught through the control system, and the main program needs to contain two instructions of branching and merging branches. Merge after branch and before branch teach a set of independent motion instructions that do not conflict with each other, which may contain calls to subroutines. The main program after teaching is also saved on the hard disk in a specific format.

[0099] (3) Load the teaching file, and the control system will analyze the teaching file at this time. Select to use the current main program to start machining operations on the CNC system. We can see that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com