Organic and inorganic mixed solar battery and manufacturing method and hole-transporting-layer forming method of organic and inorganic mixed solar battery

A hole transport layer, solar cell technology, applied in the direction of circuits, photovoltaic power generation, electrical components, etc., can solve the problems of deterioration of the electrical properties of polymer films, thinning of polymer film thickness, complex process steps, etc. Effect of reflection, increase of junction area, effect of improvement of separation and transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

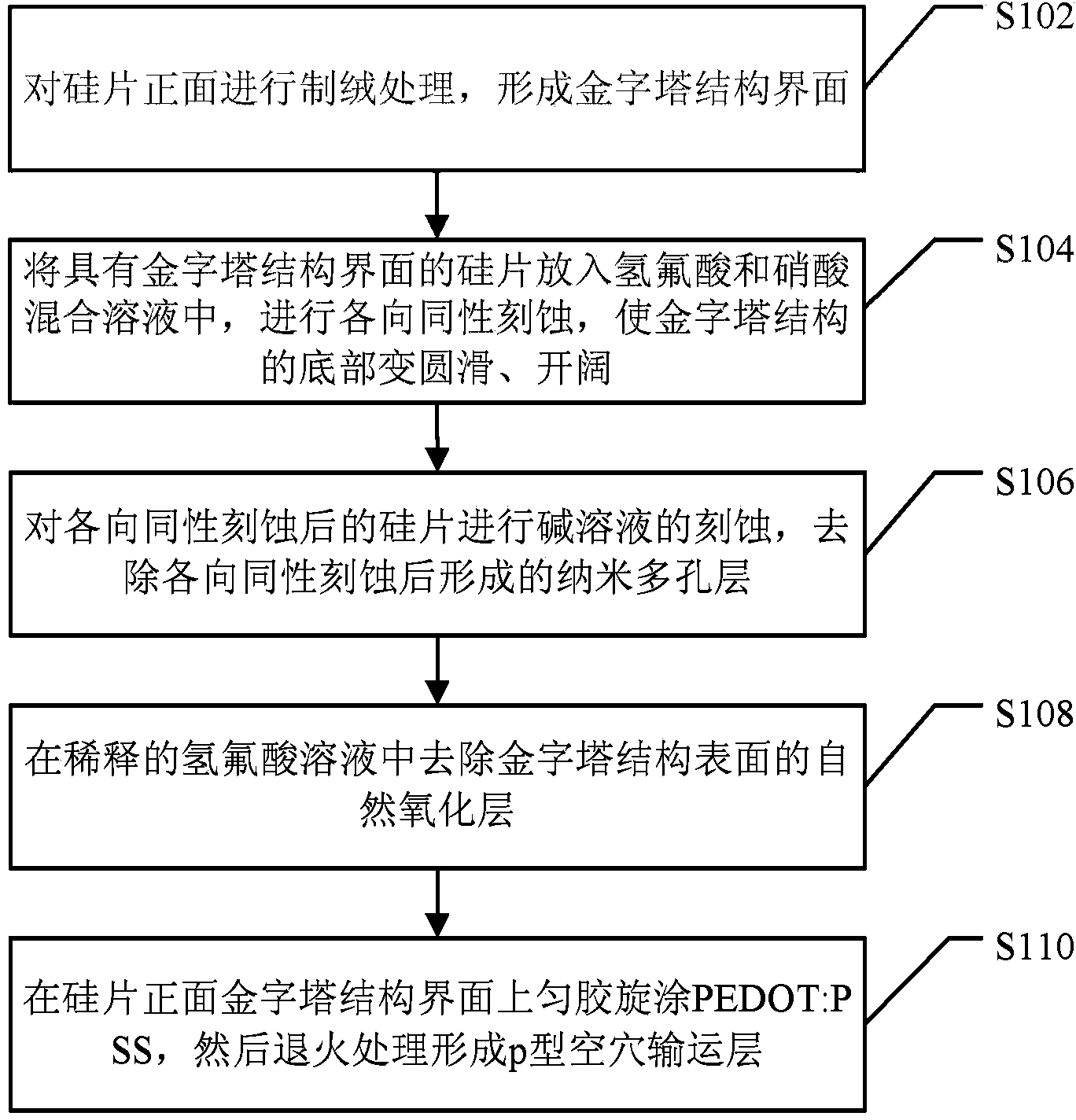

[0039] In a first exemplary embodiment of the present invention, a method for forming a hole transport layer of an organic-inorganic hybrid solar cell is provided. image 3 It is a flowchart of a method for forming a hole transport layer of an organic-inorganic hybrid solar cell according to an embodiment of the present invention. Figure 4It is a schematic longitudinal section view of an organic-inorganic hybrid solar cell according to an embodiment of the present invention. Please refer to image 3 and Figure 4 , the method for forming the hole transport layer of the organic-inorganic hybrid solar cell in this embodiment includes:

[0040] Step S102: Texturing the front side of the silicon substrate to form a pyramid structure interface;

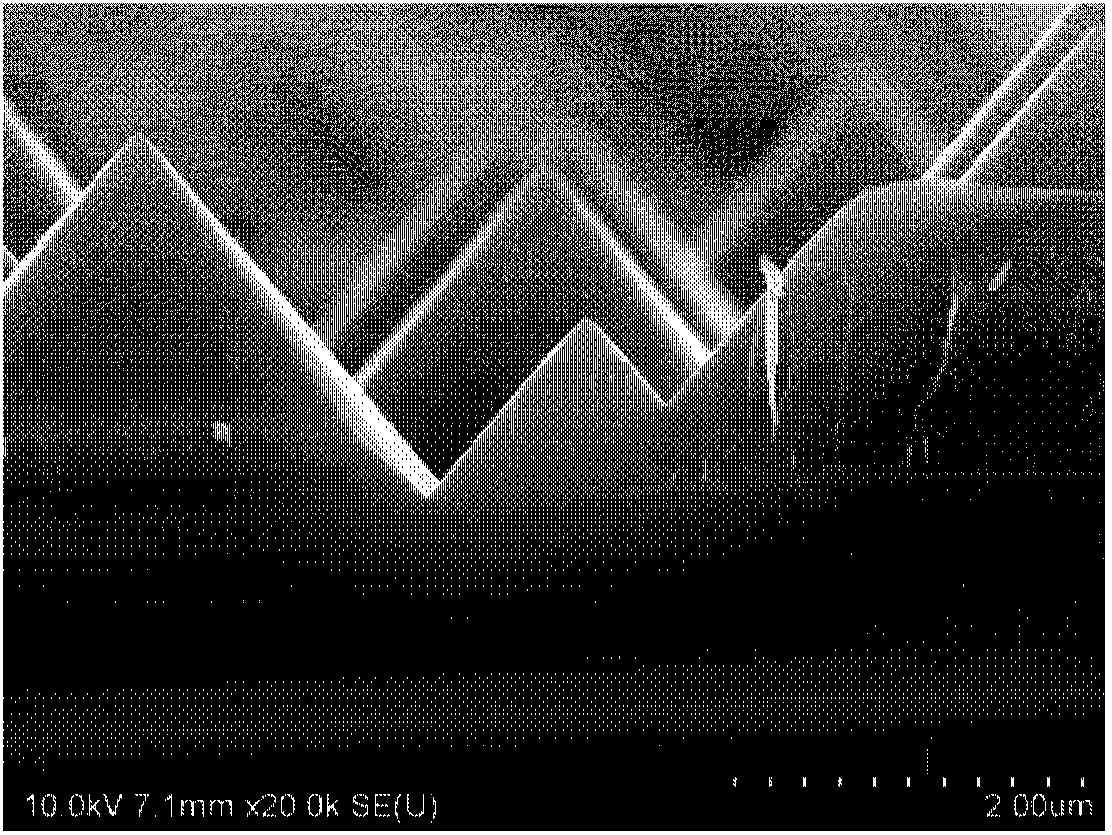

[0041] After this step, the pyramid structure interface on the front side of the silicon substrate is as follows: figure 1 shown.

[0042] In this embodiment, the silicon substrate used is (100) crystal orientation, and the method fo...

Embodiment 2

[0058] In a second exemplary embodiment of the present invention, a method for preparing an organic-inorganic hybrid solar cell is provided. Please refer to Figure 4 , the preparation method of the pyramid interface organic-inorganic hybrid solar cell of the present embodiment comprises:

[0059] Step S202: Texturing the front side of the silicon substrate to form a pyramid structure interface;

[0060] Step S204: Put the silicon substrate with the interface of the pyramid structure into a mixed solution of hydrofluoric acid and nitric acid, and perform isotropic etching to make the bottom of the pyramid structure smooth and open;

[0061] Step S206: Etching the isotropically etched silicon substrate with an alkaline solution to remove the nanoporous layer formed after isotropic etching to smooth its structure;

[0062] Step S208: removing the natural oxide layer on the surface of the pyramid structure in a diluted hydrofluoric acid solution (HF);

[0063] Step S210: therm...

Embodiment 3

[0070] In a third exemplary embodiment of the present invention, a method for preparing an organic-inorganic hybrid solar cell is provided. Please refer to Figure 4 , the preparation method of the pyramid interface organic-inorganic hybrid solar cell of the present embodiment comprises:

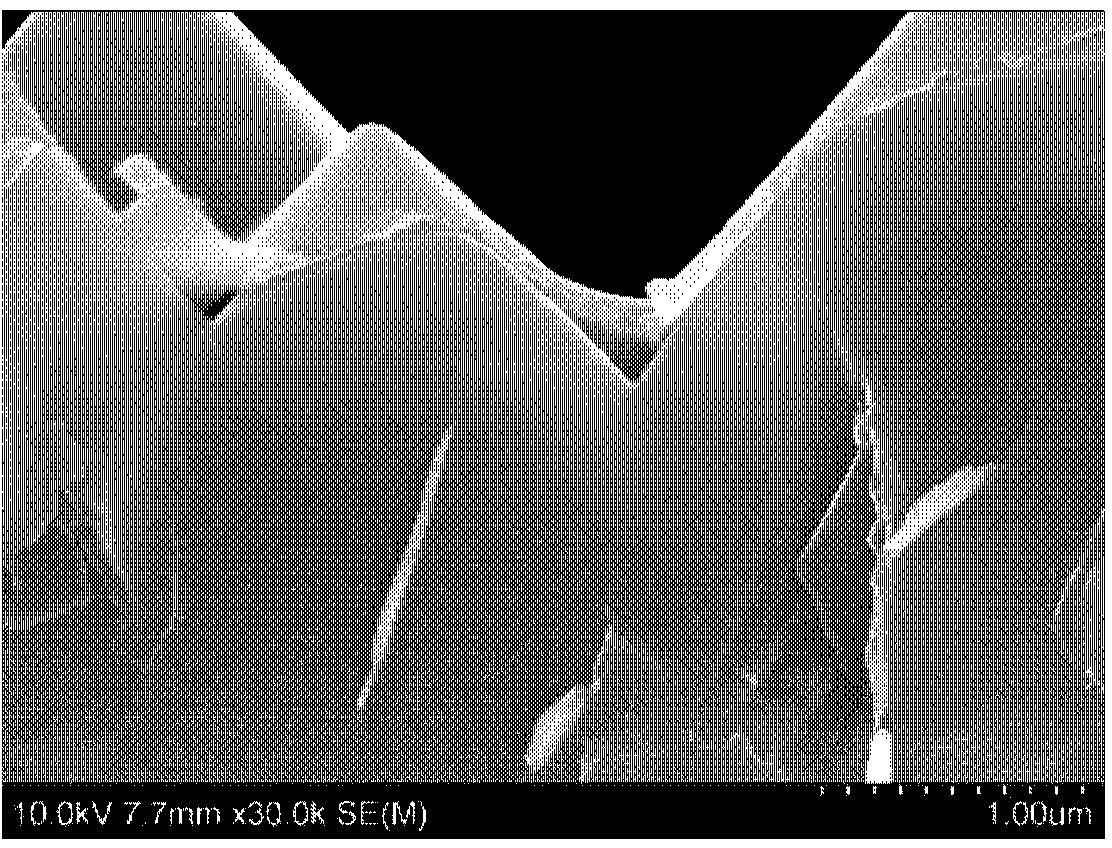

[0071] Step S302: Carry out isotropic etching with an acid solution on the n-type silicon substrate (100) after pyramid texture, wherein the concentration of HF is 0.5mol / L, and the concentration of HNO 3 The concentration is 7mol / L, and it is treated at room temperature for 4 minutes to make the bottom of the structure smooth and open, such as Figure 5 Scanning electron microscope image shown;

[0072] Step S304: Clean the silicon substrate after isotropic etching with deionized water, and then etch with 1mol / L KOH solution at room temperature for 60s to remove the nanoporous layer formed after isotropic etching, to smooth its structure, such as Figure 6 As shown in the scanning elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Short circuit current | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com