Motor and sine stator

A sine and stator technology, applied in the field of AC motors, can solve problems such as increased tooth harmonics, complex winding process, long coil ends, etc., and achieve the effect of improving slot fullness, good effect, and simple embedding of wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach ( 2

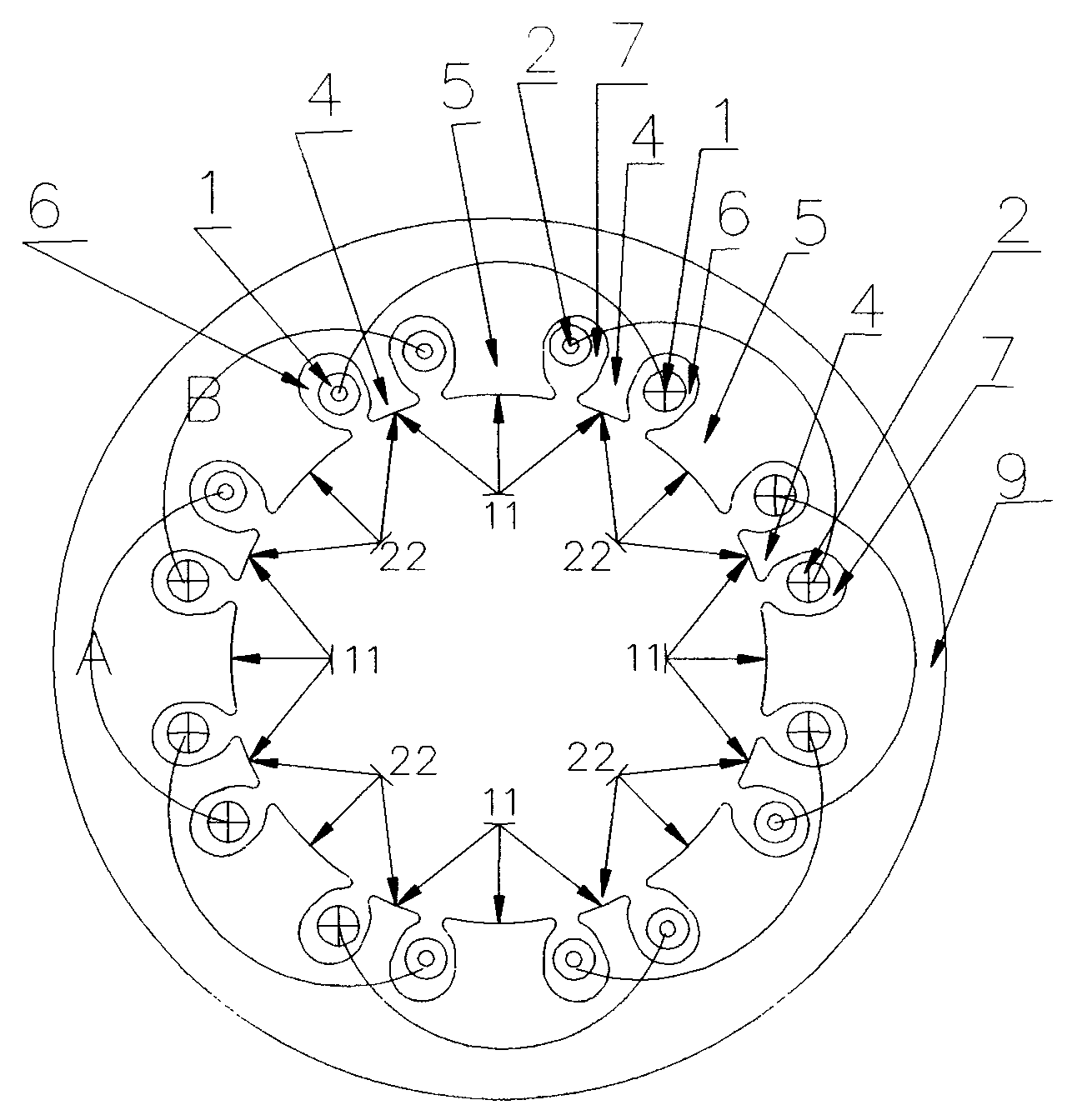

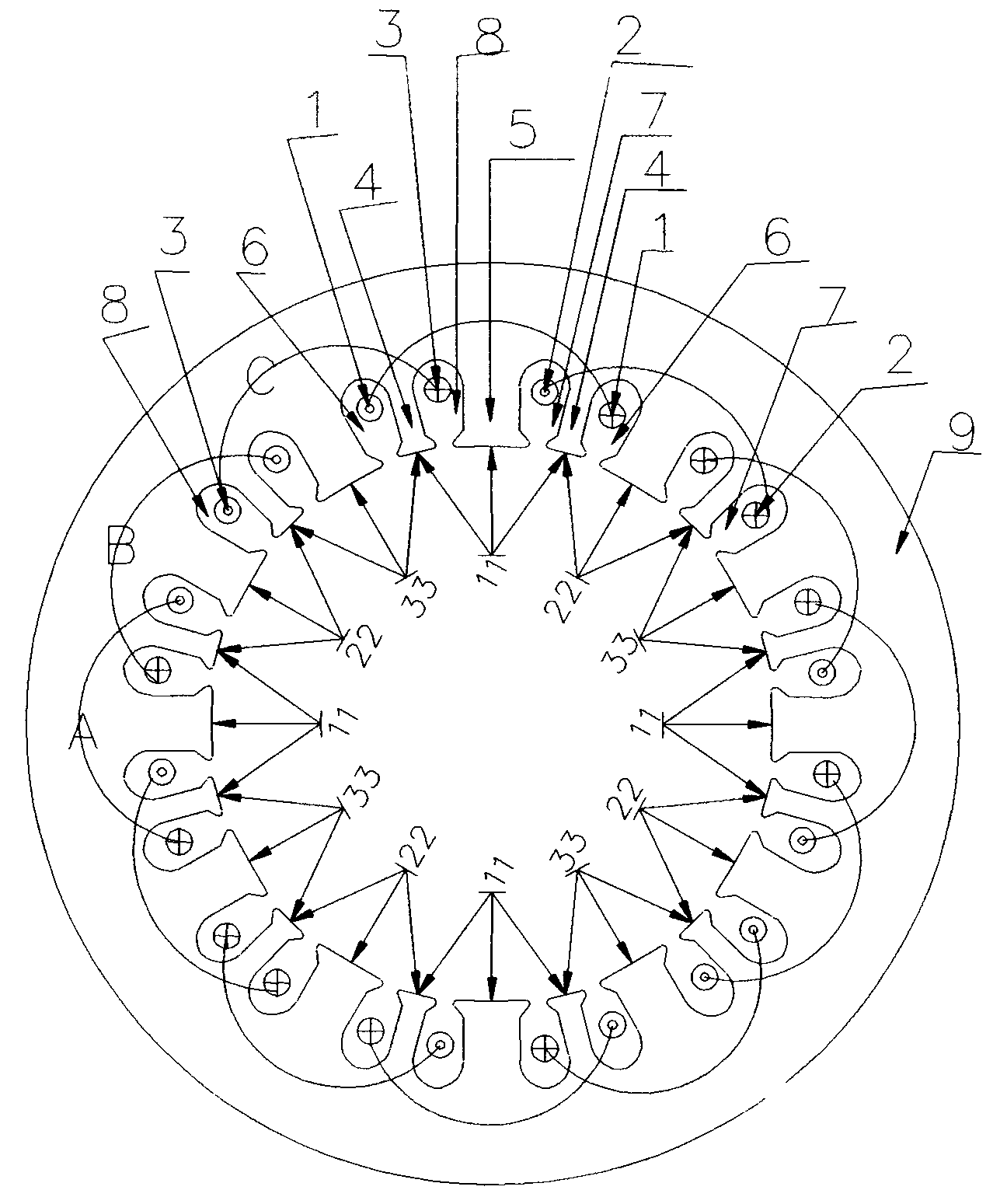

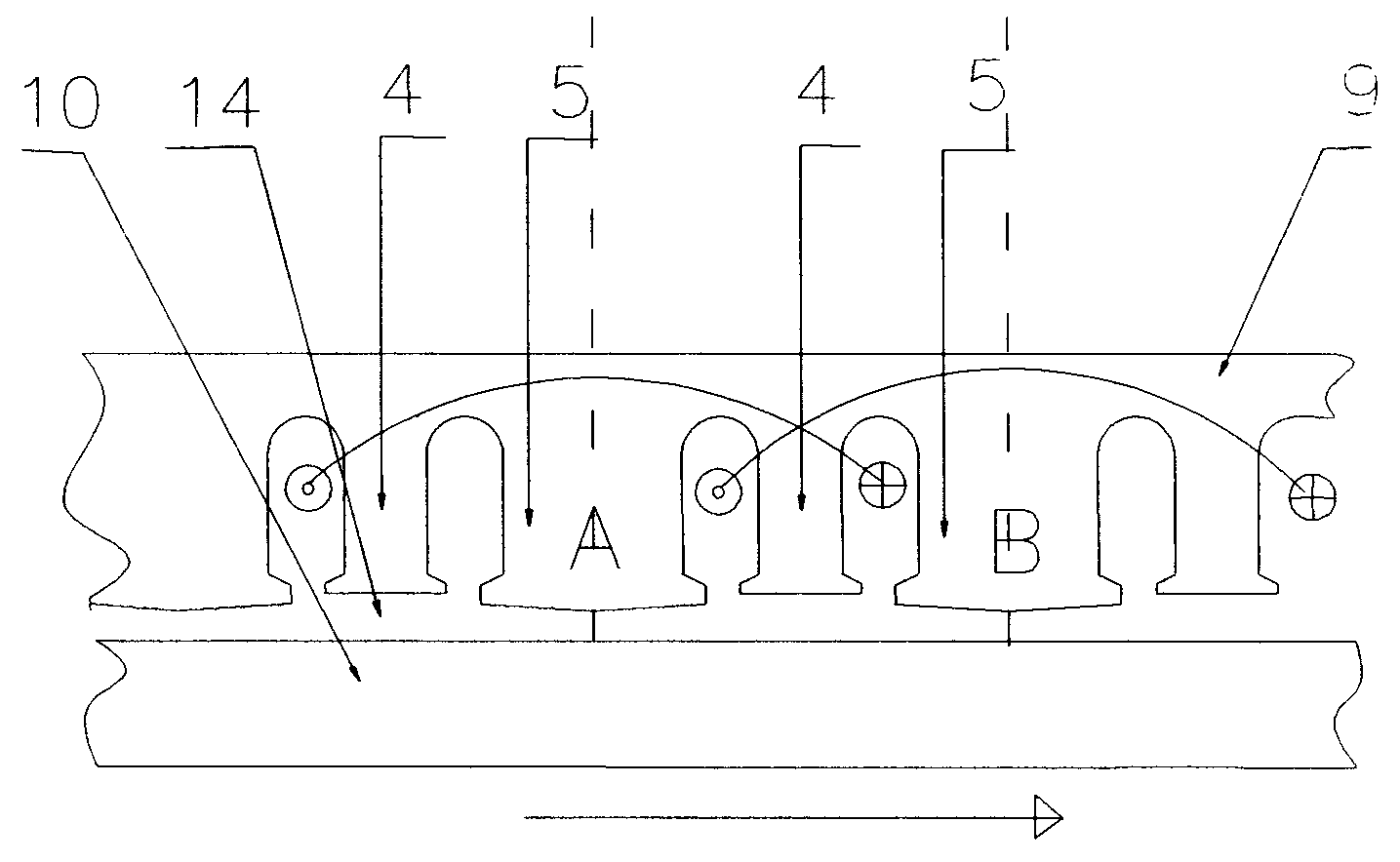

[0038] Please refer to image 3 , a motor and a sinusoidal stator are three-phase, the number of magnetic poles is four poles, there are twenty-four teeth and twenty-four slots, and the material is high magnetic permeability silicon steel sheet or silicon steel sheet.

[0039] The twenty-four slots are divided into eight A-phase slots 6, eight B-phase slots 7, and eight C-phase slots 8 with the same slot area. The slots are respectively embedded with A-phase winding 1, B-phase winding 2, and C-phase winding 3.

[0040] The twenty-four teeth are equally divided into twelve teeth 5, and twelve teeth 4 are arranged at alternating intervals in a circular shape. The arc distance between the neutral line of each tooth 5 tooth body and the tooth 4 tooth body axis is equal, and the 5 teeth The body width is twice or more than twice the body width of the tooth 4 teeth.

[0041] In this example, the body width of tooth 5 is 6mm, and the body width of tooth 4 is 2.6mm.

[0042] The arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com