Customized abutment assembly and preparation method thereof

An abutment and component technology, applied in the field of biomedical engineering, can solve the problems of many processing procedures and high processing costs, and achieve the effects of improving aesthetic effects, avoiding damage and saving medical costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

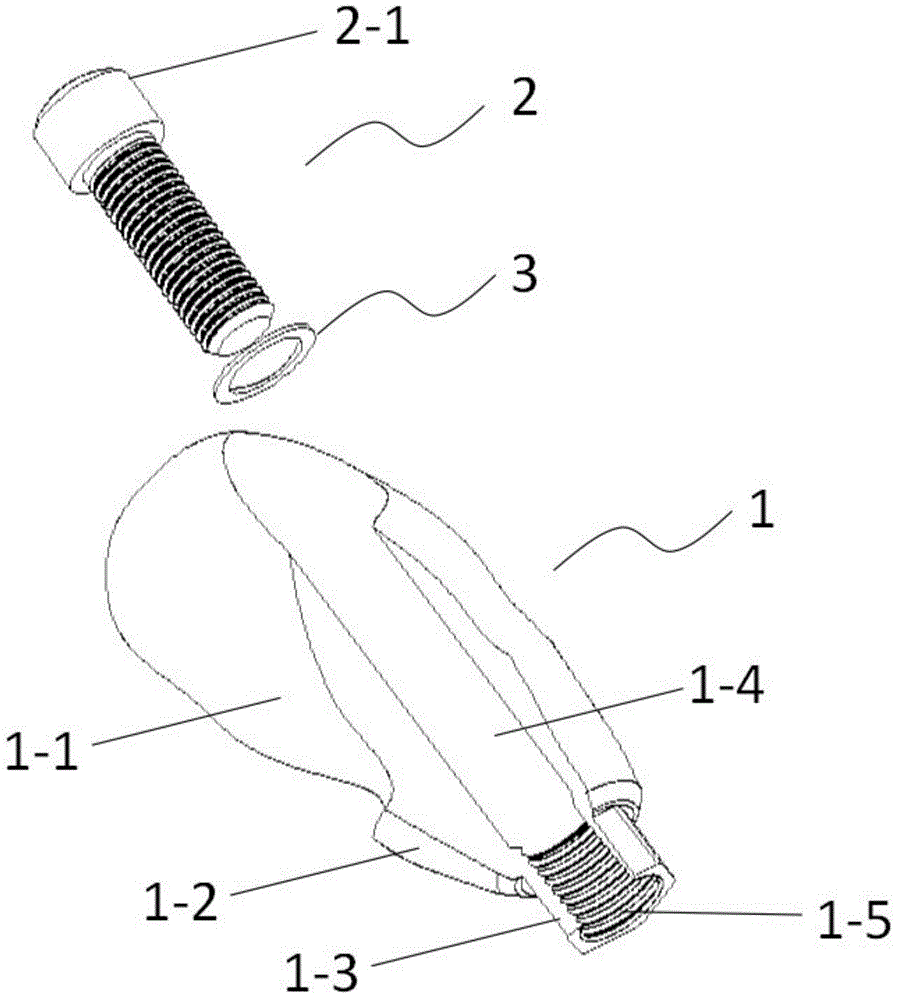

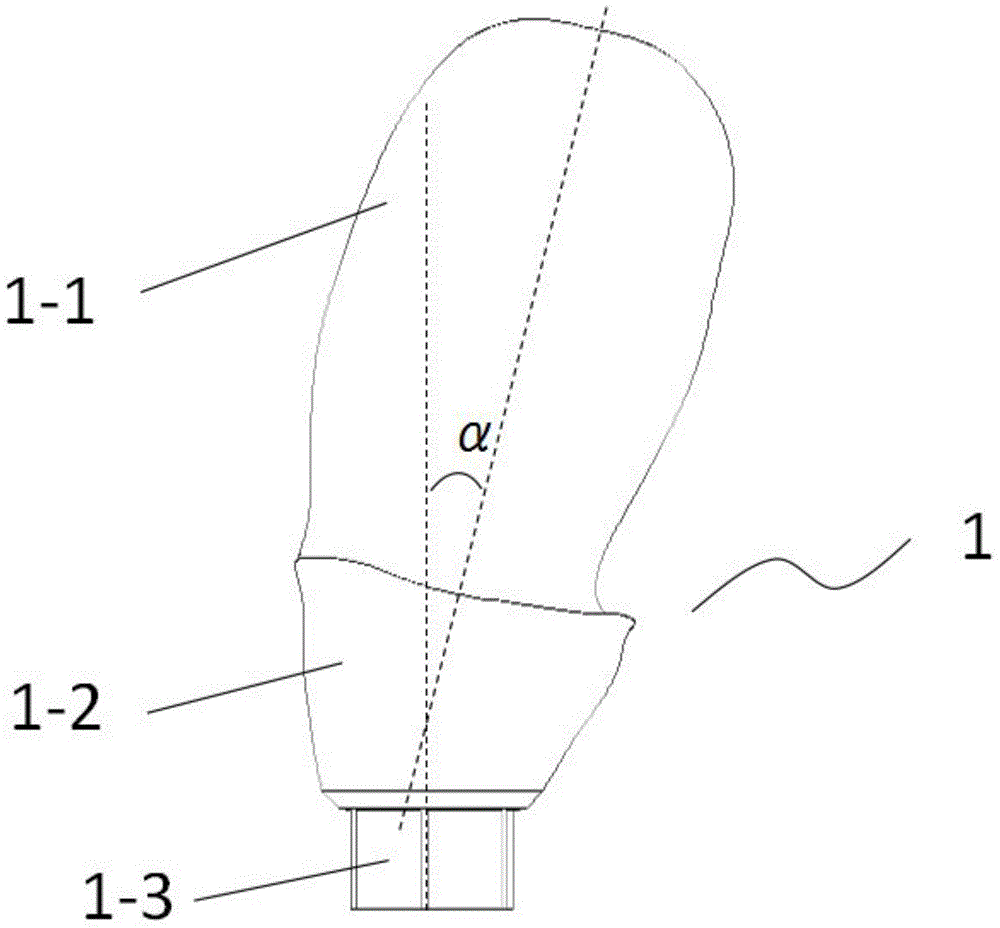

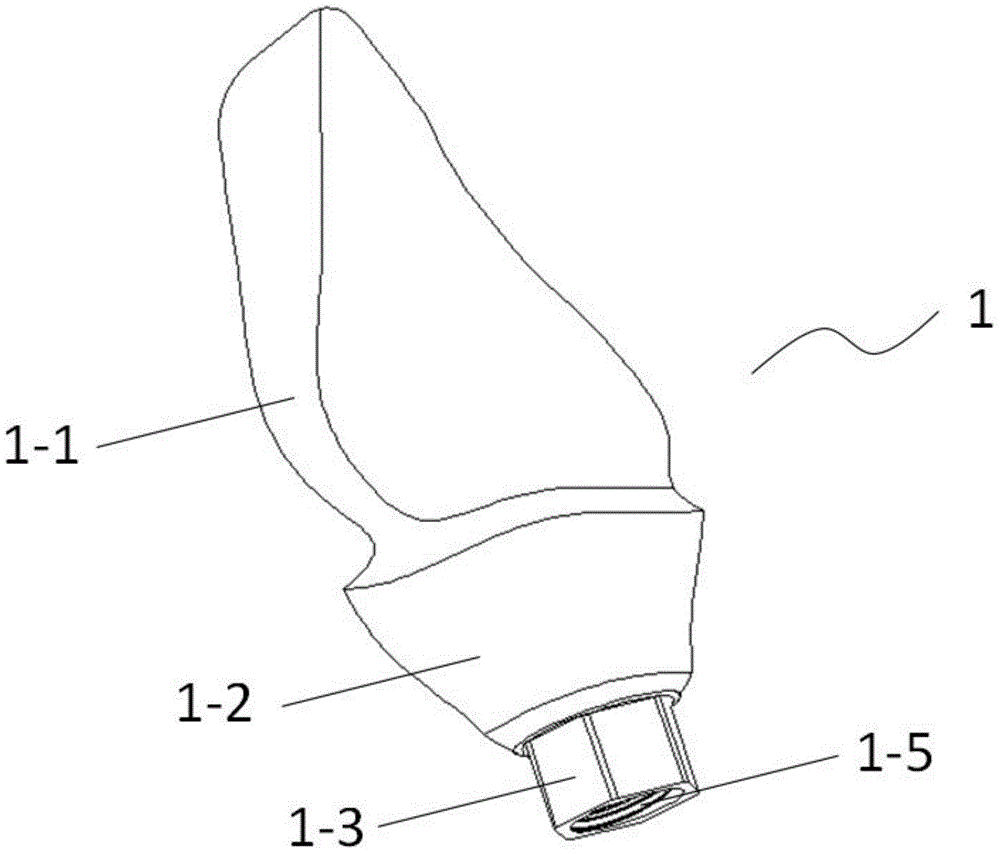

[0041] (1) Specific implementation mode one: a kind of personalized abutment assembly, it is characterized in that: such as figure 1 As shown, it includes the abutment body 1, the fixing bolt 2 and the anti-loosening washer 3 connected between the implant and the abutment body 1, and the abutment body 1 includes a crown connection section 1-1, a gingival section 1-2 and the implant connection section 1-3, the abutment body is provided with a stepped hole that runs through the crown connection section 1-1, the gingival section 1-2 and the implant connection section 1-3, and the step One end of the hole located at the implant connection section 1-3 is a threaded hole 1-5 matching the fixing bolt 2, and the other end is a light hole 1-4 with a diameter slightly larger than the outer diameter of the bolt head 2-1 of the fixing bolt 2; The abutment angle α and abutment shape of the abutment body 1 are personalized abutments made according to the angle and shape of the patient's too...

specific Embodiment approach 2

[0052] (2) Embodiment 2: A method for preparing a personalized abutment assembly, characterized in that: the method includes sequential 3D scanning, CAD modeling, 3D printing and heat treatment;

[0053] The 3D scanning is to obtain the crown connection section 1-1, the gingival section 1-2 and the implant connection section of the abutment body 1 by scanning the plaster model of the patient's tooth with a 3D scanner or directly scanning the tooth in the patient's mouth 1-3 angle and shape information;

[0054] The CAD modeling is based on the data scanned by 3D software, combined with the tooth position and shape of the patient's affected teeth to design a personalized abutment that meets the requirements, and then performs three-dimensional slice processing on the designed personalized abutment, each layer The thickness is 10-50μm, and the processed data is stored in CL file format;

[0055] The 3D printing includes the following steps in order: ① input CL file; ② titanium-...

preparation example 1

[0061] Prepare personalized implant abutments according to the Zmmer implant system in the United States. First, use a 3D laser scanner to scan the plaster model in three dimensions, and obtain the shape of the abutment body, shoulder, denture connection, gingiva, and abutment angle from the plaster model. and other information; such as image 3 As shown, the interface of the abutment connection part is hexagonal, the abutment angle α is 3°, and the cone angle of the lower part of the abutment through the gingiva is 4°; then use Solidworks 3D software, according to the data obtained by scanning, combined with the patient's body The position and shape of the teeth are designed to meet the requirements of personalized abutments. The length of the implant connecting section is 2mm, and the inner side is provided with a thread with a pitch of 0.2mm; the thickness of the anti-loosening gasket is 0.2mm; the fixing bolts are fully threaded bolts with a pitch of 0.2mm; then the design...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com