Paramagnetic metal complex modified by aspartic acid-phenylalanine copolymer and its preparation method and application

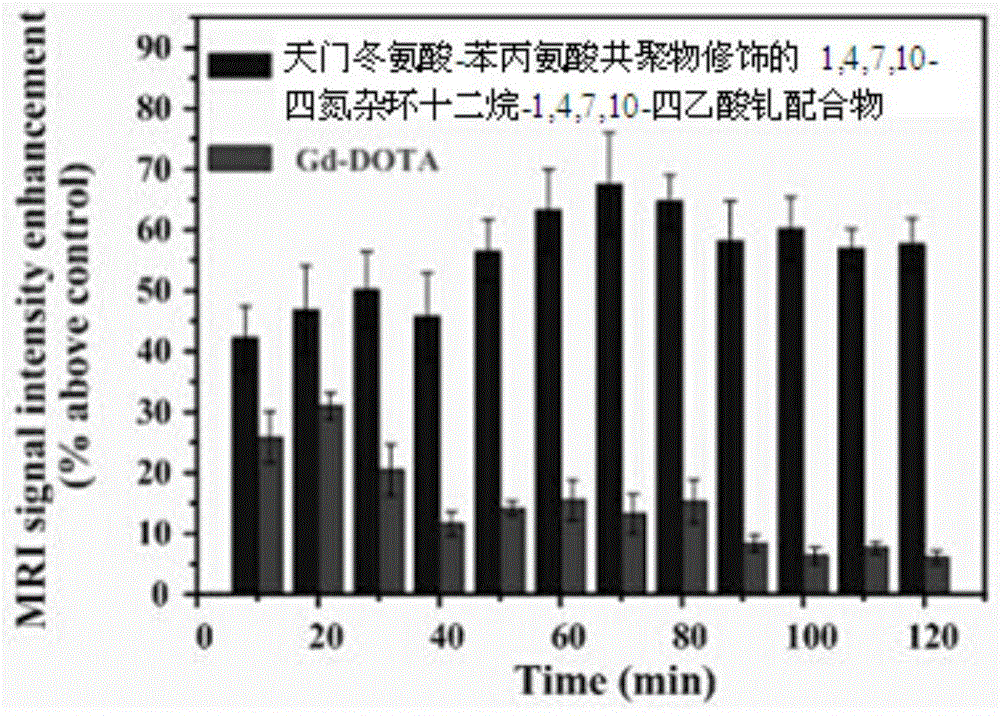

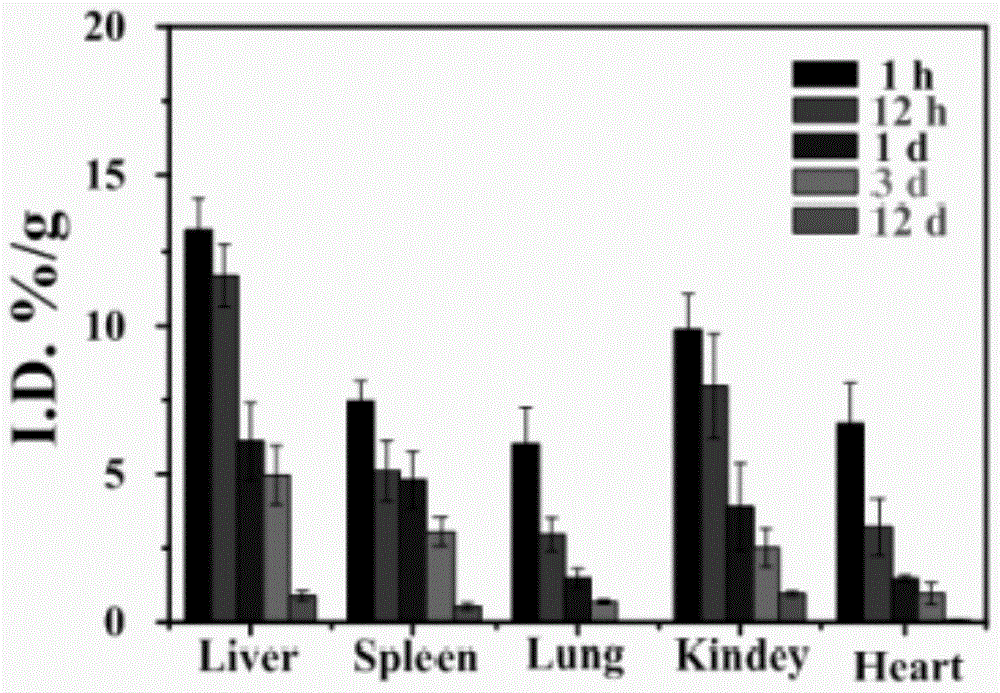

A technology of phenylalanine copolymer and aspartic acid, which can be used in preparations and pharmaceutical formulations for in vivo experiments, can solve the problems of low biodegradability, liver targeting and low immunity, and achieve imaging time. Long, good water solubility, good imaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Preparation of aspartic acid-phenylalanine copolymer via 1,4,7,10-tetraazacyclododecane-1,4,7,10-tetraacetate gadolinium complex modified by ethylenediamine

[0046] (1) Mix 20 grams of L-aspartic acid with 10 grams of L-phenylalanine, add 10 grams of the mass fraction of the mixed mixture into 85% phosphoric acid solution and stir evenly. (24mmHg) for 5 hours, the reaction temperature was controlled at 165°C, precipitated with deionized water, filtered, washed, and dried under reduced pressure to obtain an aspartic acid-phenylalanine copolymer;

[0047] (2) Dissolve the aspartic acid-phenylalanine copolymer synthesized in (1) in N,N-dimethylformamide solution at room temperature, and add ethylenediamine and ethylenediamine dropwise while stirring. The mass ratio of amine to aspartic acid-phenylalanine copolymer was 2.8:1, stirred at room temperature for 4 hours, precipitated with ether, filtered, dialyzed, and freeze-dried to obtain aminated aspartic acid-phenylalanine...

Embodiment 2

[0051] Preparation of aspartic acid-phenylalanine copolymer via 1,4,7,10-tetraazacyclododecane-1,4,7,10-tetraacetate gadolinium complex modified by ethylenediamine

[0052] (1) Mix 20 grams of L-aspartic acid with 20 grams of L-phenylalanine, add 15 grams of the mass fraction of the mixed mixture into 85% phosphoric acid solution and stir evenly. (30mmHg) for 5 hours, the reaction temperature was controlled at 165°C, precipitated with deionized water, filtered, washed, and dried under reduced pressure to obtain an aspartic acid-phenylalanine copolymer;

[0053] (2) Dissolve the aspartic acid-phenylalanine copolymer synthesized in (1) in N,N-dimethylformamide solution at room temperature, and add ethylenediamine and ethylenediamine dropwise while stirring. The mass ratio of amine to aspartic acid-phenylalanine copolymer was 2.8:1, stirred at room temperature for 4 hours, precipitated with ether, filtered, dialyzed, and freeze-dried to obtain aminated aspartic acid-phenylalanine...

Embodiment 3

[0057] Preparation of aspartic acid-phenylalanine copolymer via 1,4,7,10-tetraazacyclododecane-1,4,7,10-tetraacetate gadolinium complex modified by ethylenediamine

[0058] (1) Mix 20 grams of L-aspartic acid with 20 grams of L-phenylalanine, add 15 grams of the mass fraction of the mixed mixture into 85% phosphoric acid solution and stir evenly. (200mmHg) for 5 hours, the reaction temperature was controlled at 100°C, precipitated with deionized water, filtered, washed, and dried under reduced pressure to obtain an aspartic acid-phenylalanine copolymer;

[0059] (2) Dissolve the aspartic acid-phenylalanine copolymer synthesized in (1) in N,N-dimethylformamide solution at room temperature, and add ethylenediamine and ethylenediamine dropwise while stirring. The mass ratio of amine to aspartic acid-phenylalanine copolymer was 2.8:1, stirred at room temperature for 4 hours, precipitated with ether, filtered, dialyzed, and freeze-dried to obtain aminated aspartic acid-phenylalanin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com