Laser scanning method used for fast forming high-temperature alloy structural member

A high-temperature alloy and laser scanning technology, which is applied in the field of metal powder melting and forming, is suitable for promotion and application, avoids stress deformation and cracking problems, and has a high degree of controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

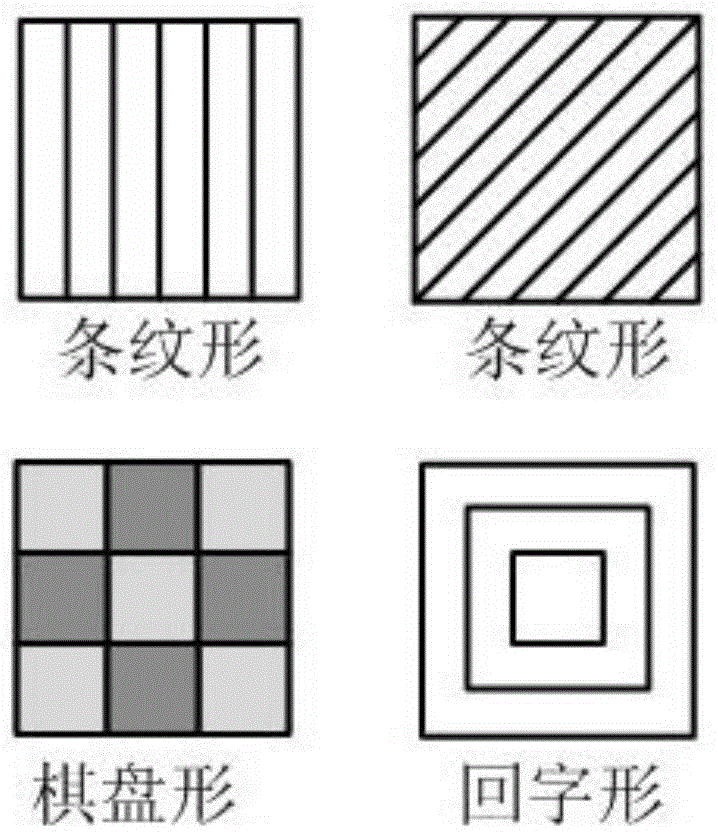

[0032] A high-temperature alloy slice layer is divided into three areas A1, B1, and C1, and the area S of the A1 area is 0.15mm 2 , using the "back" shape scanning method, the area S of B1 area is 0.5mm 2 , using the stripe-shaped scanning method, the area S of the C1 area is 2.0mm 2 , using the checkerboard scanning method;

[0033] The particle size of the powder is 20 μm, and the layer thickness is 50 μm;

[0034] The scanning power of the laser is 200W, the scanning speed is 600mm / s, the scanning point distance is 20μm, and the scanning distance is 0.1m during the forming scanning; the scanning power of the laser is 150W, the scanning speed is 1000mm / s, and the scanning point distance is 10μm. Scanning distance 0.05mm;

[0035] The laser wavelength range is 980nm, and the protective gas is argon.

Embodiment 2

[0037] A high-temperature alloy slice layer is divided into three areas: A2, B2, and C2, and the thickness H of the structural part in the scanning area of A2 is 0.4mm 2 , using the "back" shape scanning method, the thickness H of the structural part in the B2 scanning area is 1.0mm 2 , using the stripe-shaped scanning method, the thickness H of the structural part in the C2 scanning area is 6mm 2 , using the checkerboard scanning method;

[0038] The particle size of the powder is 25 μm, and the layer thickness is 45 μm;

[0039] The scanning power of the laser is 250W, the scanning speed is 700mm / s, the scanning point pitch is 30μm, and the scanning spacing is 0.2m during the forming scanning; the scanning power of the laser is 160W, the scanning speed is 1100mm / s, and the scanning point pitch is 15μm when scanning the outer surface. Scanning distance 0.06mm;

[0040] The laser wavelength range is 1.07μm, and the protective gas is argon.

Embodiment 3

[0042] A high-temperature alloy slice layer is divided into three areas A3, B3, and C3, and the area S of the A3 area is 0.1mm 2 , using the "back" shape scanning method, the area S of B3 area is 0.8mm 2 , using the stripe-shaped scanning method, the area S of the C3 area is 3.0mm 2 , using the checkerboard scanning method;

[0043] The particle size of the powder is 30 μm, and the layer thickness is 45 μm;

[0044]The scanning power of the laser is 400W, the scanning speed is 1000mm / s, the scanning point pitch is 50μm, and the scanning spacing is 0.5m during the forming scanning; the scanning power of the laser is 200W, the scanning speed is 1500mm / s, and the scanning point pitch is 30μm when scanning the outer surface. Scanning distance 0.2mm;

[0045] The laser wavelength range is 9.6 μm, and the protective gas is argon.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com