Preparation method of narrow and thin superhard material grinding wheel ring and fixture for implementing the method

A technology of superhard material and grinding wheel, applied in the field of abrasives manufacturing, can solve the problems of low production efficiency, low yield of narrow and thin superhard material grinding wheel ring, poor precision, etc. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

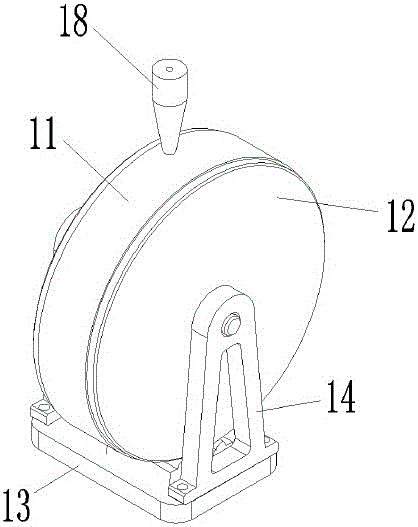

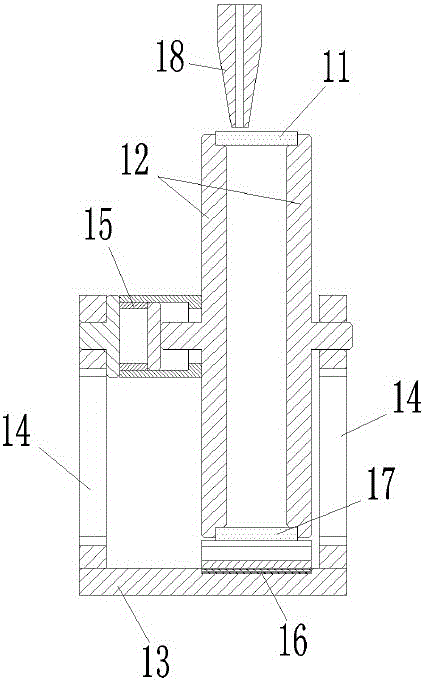

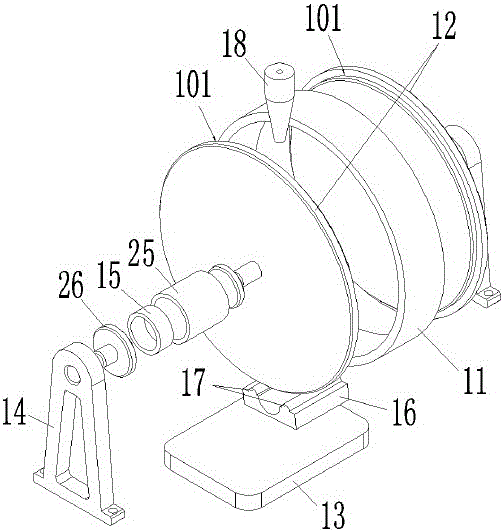

[0022] The embodiment of the preparation method of the narrow and thin superhard material grinding wheel ring, such as Figure 1-3 As shown, the method includes the following steps: (1) making a grinding wheel ring blank 11; (2) drying the grinding wheel ring blank 11 prepared in step (1), and then sintering and solidifying; (3) performing the step ( 2) The processed grinding wheel ring blank 11 is divided to obtain the grinding wheel ring to be manufactured.

[0023] The grinding wheel ring blank 11 described in step (1) is actually a larger grinding wheel ring, the width dimension of which is slightly larger than the width dimension of the grinding wheel ring to be manufactured, and the thickness dimension (axial dimension) is an integral multiple of that of the grinding wheel ring to be manufactured The thickness dimension of the grinding wheel ring, wherein the width dimension of the grinding wheel ring blank is more than the width dimension of the grinding wheel ring to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com