Bamboo floor mold pressing production process and equipment

A production process, the technology of bamboo flooring, applied in the field of flooring materials, can solve the problems of high cost, obvious bamboo joints, single color, etc., and achieve the effect of simple production process, short time period, and no rebound of embossing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

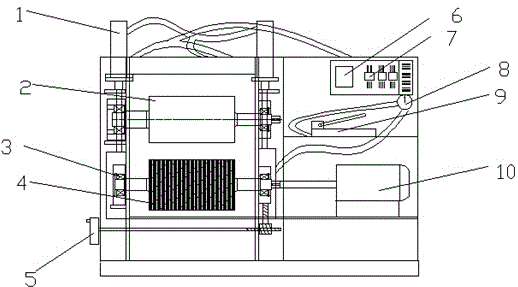

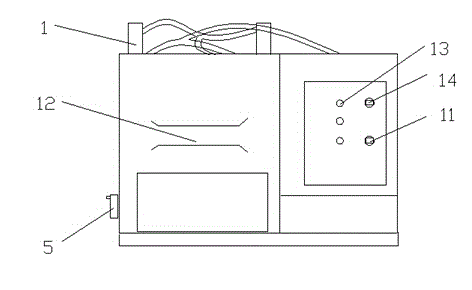

[0021] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0022] A molding production process for bamboo flooring, including selection of moso bamboo, cutting, splitting, rough planing, cooking, bleaching or carbonization, drying, fine planing of bamboo strips, sorting, gluing and forming blanks, hot-press gluing, sanding, and lengthening Cutting, four-sided planing, double-end milling, vertical and horizontal tenoning, surface coating, inspection, and packaging processes. The specific operating conditions of each process are the same as the existing process. After the sanding process, it is also included in the embossing process. Embossing machine, embossing machine pressure 3-8kg / MPA, temperature control range 200°C-240°C, evolution of traditional fire bending technology, to prevent embossing rebound of bamboo flooring.

[0023] according to figure 1 and figure 2 Shown:

[0024] In order to realize the embossing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com