Extrusion moulding machine for two-row equal-number staggered hole slat

A molding machine and slat technology, applied to ceramic molding machines, manufacturing tools, etc., can solve the problems of large slats, bulky, poor sound insulation effect of single-layer slats, etc., and achieve the effect of solving the offset of the plate holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

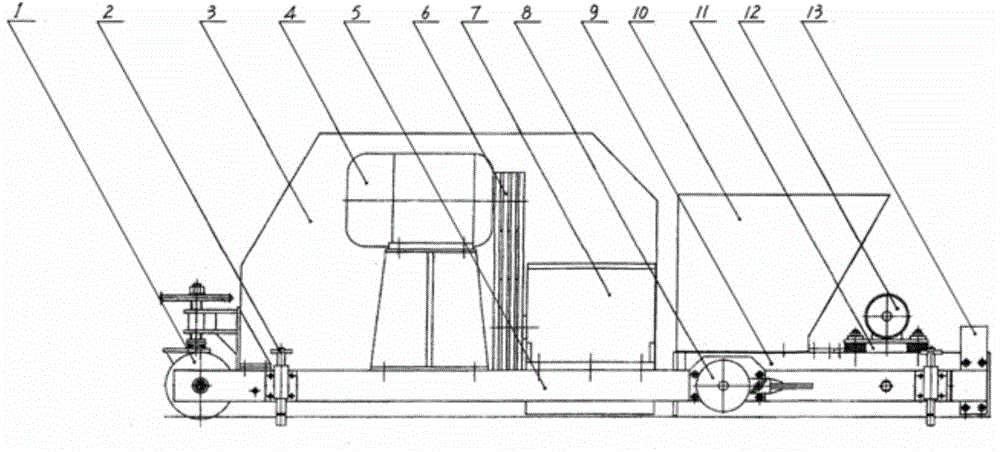

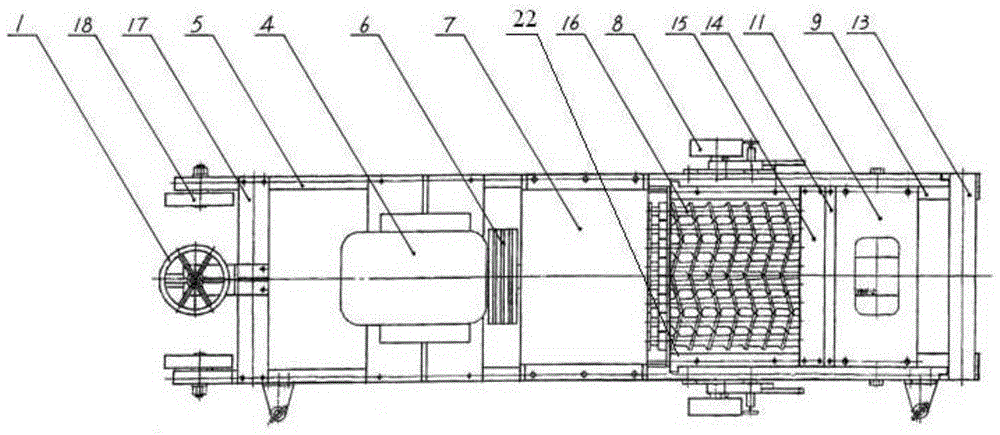

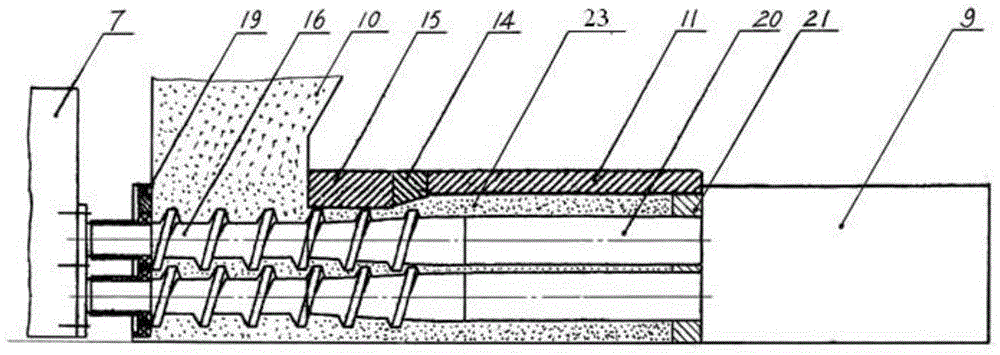

[0016] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

[0017] Please refer to figure 1 and figure 2 , the double-row extrusion molding machine with the same number of staggered holes of the present invention comprises a base, a shell cover 3, a main motor 4, a gearbox 7, a hopper 10, a vibrating motor 12, a vibrating plate 11 and a mold frame 22, and the base is composed of left and right longitudinal Beam 5, front beam 17, portal beam 13 are connected and form. The output shaft of the main motor 4 is connected with the input shaft of the gearbox 7 through the transmission belt 6 , and two layers of multiple screw rods 16 are arranged in parallel in the mold frame 22 . The discharge port of the hopper 10 is arranged above the feeding section of two layers of multiple screws 16 . The base 5 is provided with a walking wheel 8 , a direction wheel 1 , a gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com