Self-dedusting device of coke oven coal tower loading truck

A self-dusting and coal tower technology, applied in coke ovens, furnaces to prevent/remove fouling, petroleum industry, etc., can solve the problems of loss, burns, pollution of coal resources, etc., and achieve the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

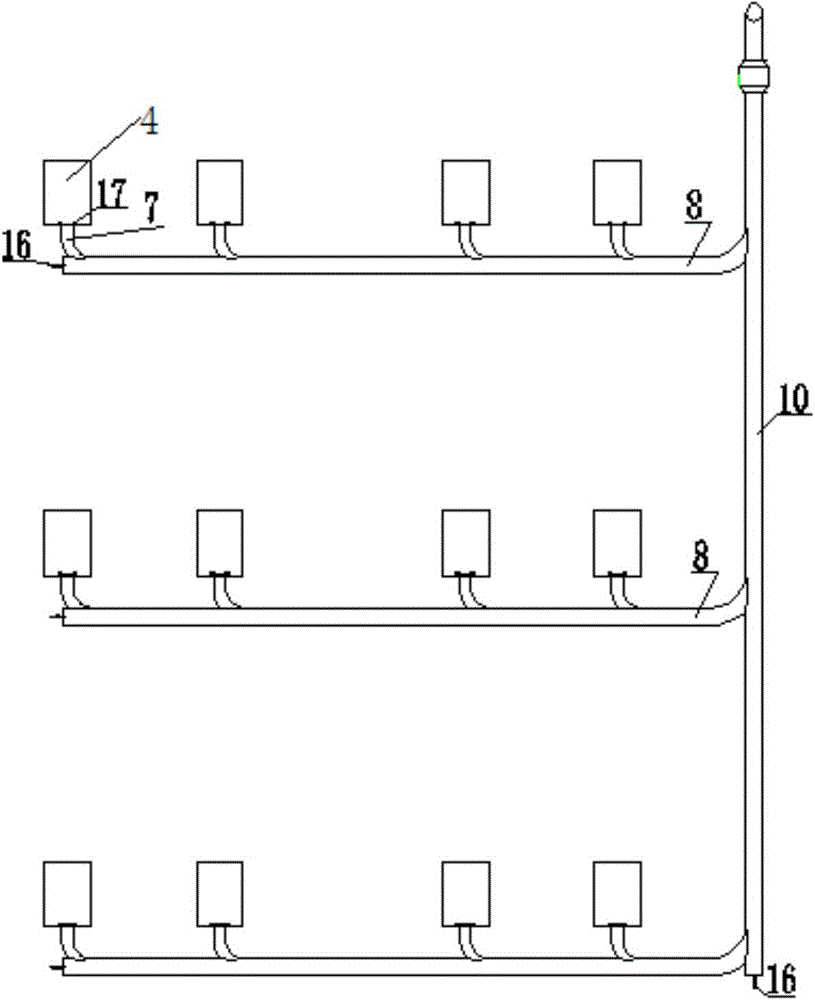

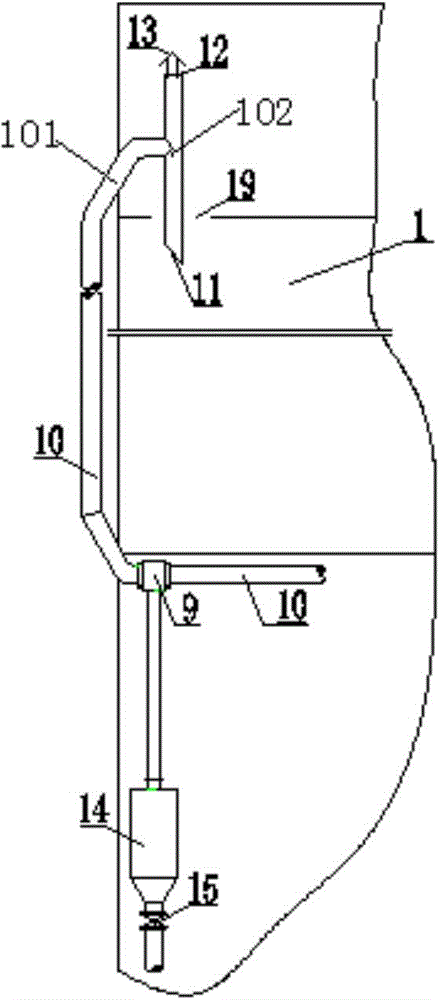

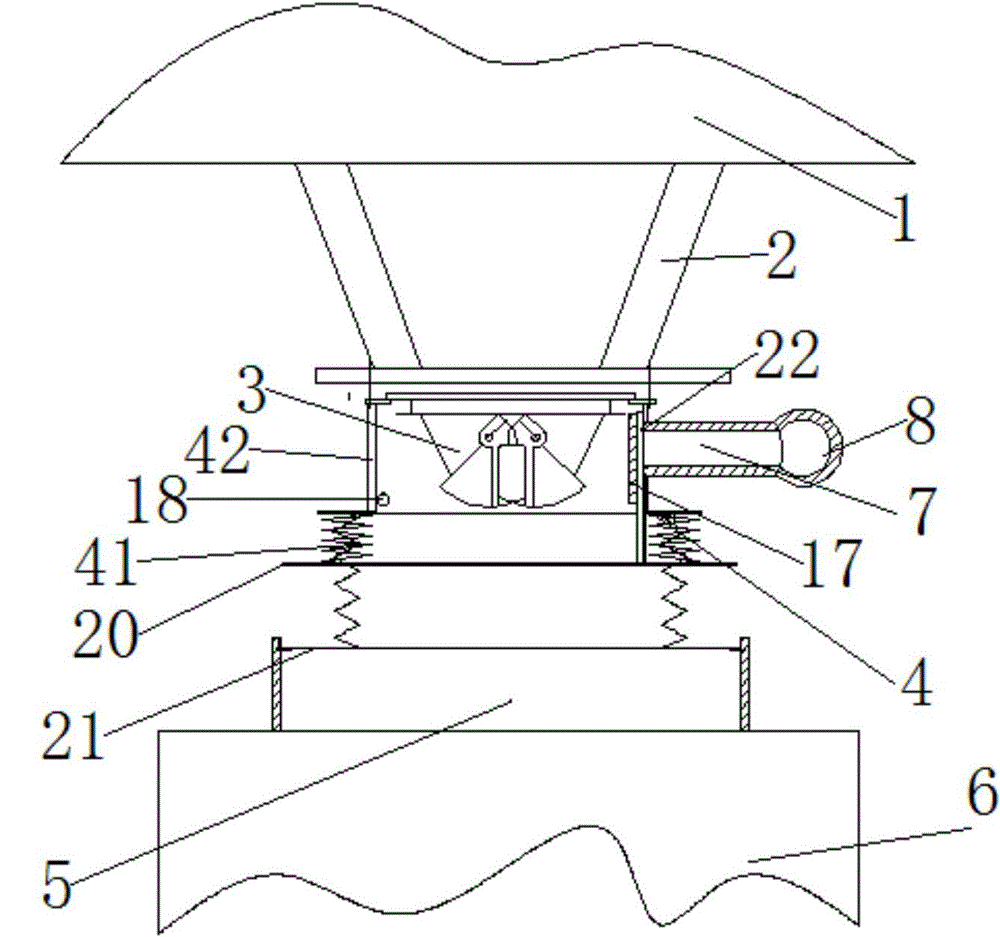

[0014] The specific implementation manner of the present invention is illustrated in conjunction with embodiment, as figure 1 with image 3 As shown, the coke oven coal tower loading self-dust removal device includes a sealed channel 4 and a coal discharge valve 3. The coal discharge valve 3 is enclosed in the sealed channel 4, and the inlet of the coal discharge valve 3 is connected to the lower part of the coal tower 1. On the end of the coal tower nozzle 2; the sealing passage 4 includes a fixed section 42 with a flange and a bellows section 41, the top of the fixed section 42 is connected to the coal tower nozzle 2 through a flange, and the top of the bellows section 41 is connected below the fixed section 42 , the tail of the bellows section 41 is extended to connect with the interface 5 of the coal hopper 6 of the coal loading vehicle;

[0015] The fixed section 42 is connected with a branch air duct 7, and the connection or disconnection between the branch air duct 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com