Natural gas purification device

A natural gas and equipment technology, applied in the field of natural gas purification equipment, can solve problems such as being easily affected by weather changes, heavy workload, and high difficulty intensity, and achieve the effects of shortening on-site installation time, innovation and shortening, and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

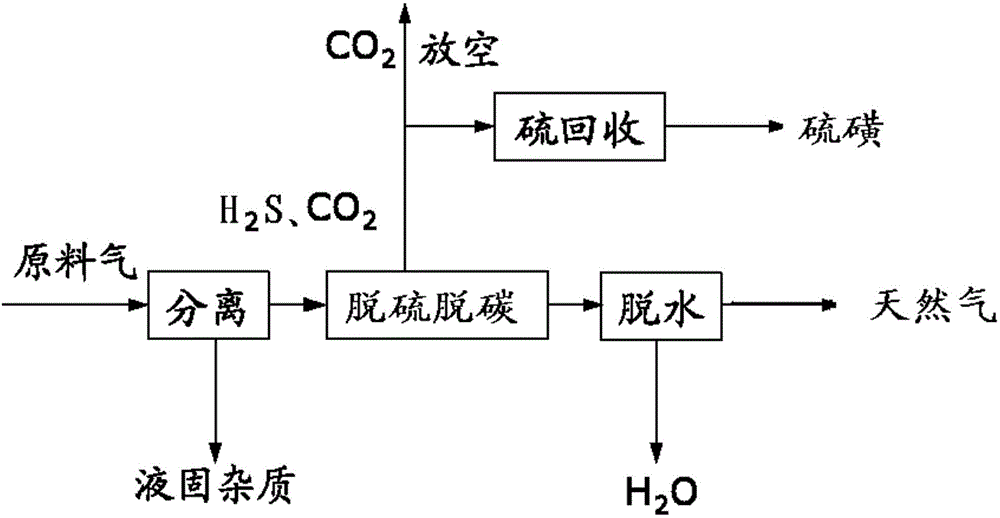

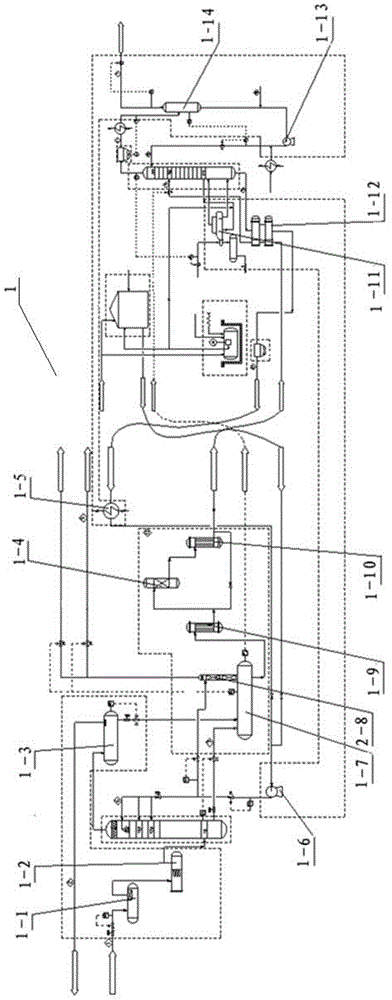

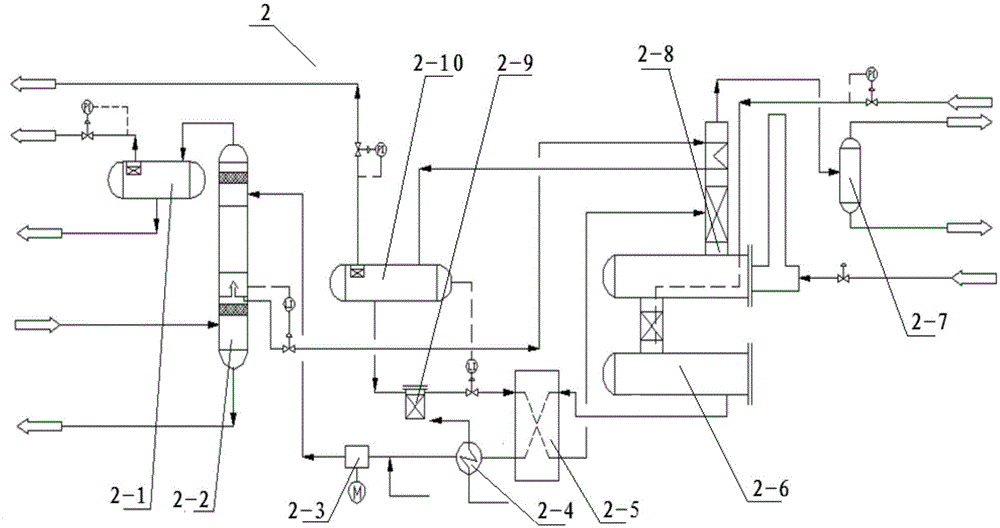

[0021] The natural gas purification equipment adopts a modular design, and the modules are divided according to the functions to be realized, and the components are integrated into a feed gas pretreatment unit, a desulfurization and decarbonization unit 1, a dehydration unit 2 and a sulfur recovery unit 3, and each unit is installed on the skid. , the feed gas pretreatment unit, the desulfurization and decarbonization unit 1 and the dehydration unit 2 are connected in sequence, and the sulfur recovery unit 3 is connected with the desulfurization and decarbonization unit 1 . Each unit completes the manufacturing of the skid body, the in-place installation of process equipment, electrical appliances, instruments, and process pipelines in the manufacturing plant, the purging of process equipment and pipelines, pressure testing, anti-corrosion and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com