A kind of damping combined building shock-isolation rubber bearing and its manufacturing method

A shock-absorbing rubber and manufacturing method technology, applied in the direction of building structure, construction, building components, etc., can solve the problems of the decline of the ultimate shear deformation capacity of the support, the large area of the lead core and the rubber body, and the decline in the overall performance of the support. , to achieve the effect of improving the shock absorption and isolation effect, excellent fatigue resistance, flexural performance and weather resistance, comprehensive and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

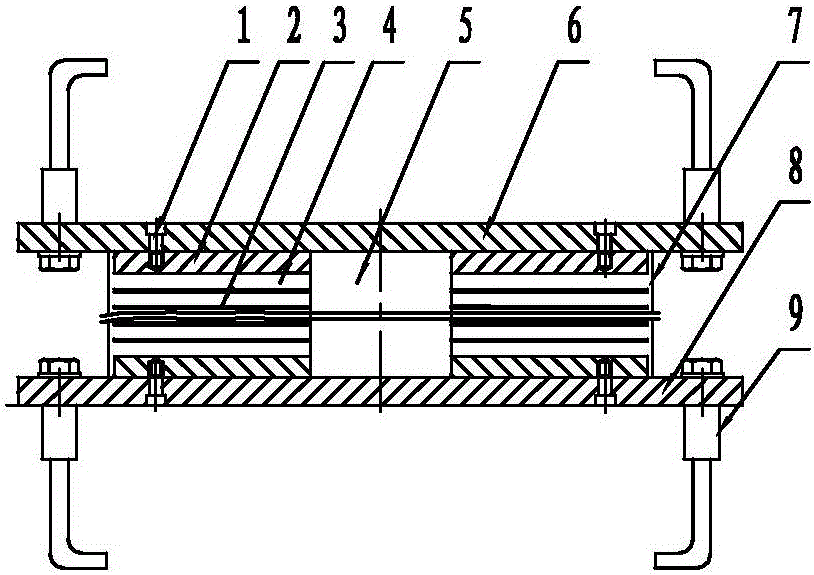

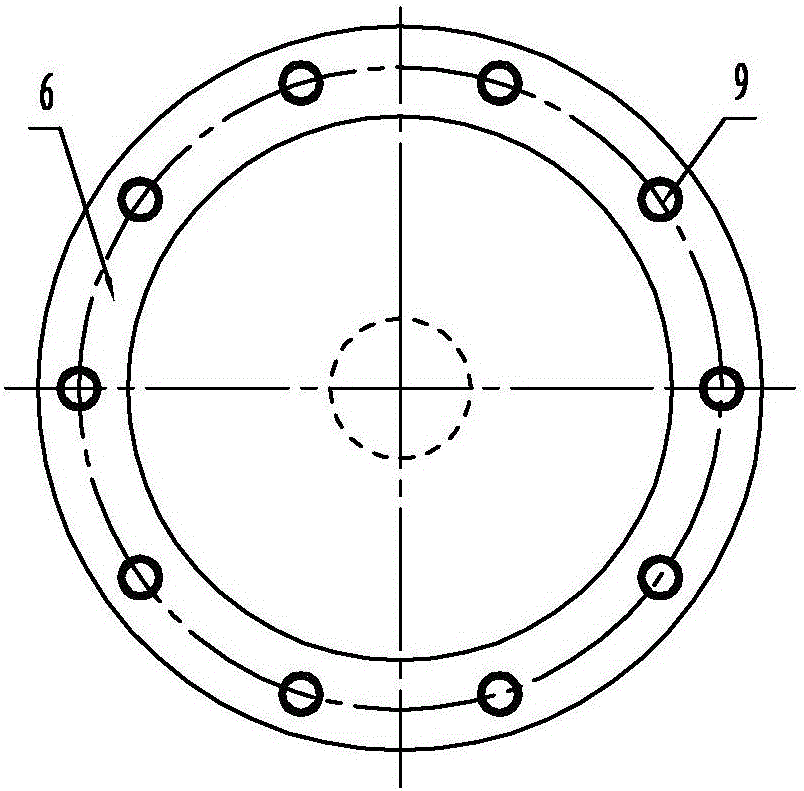

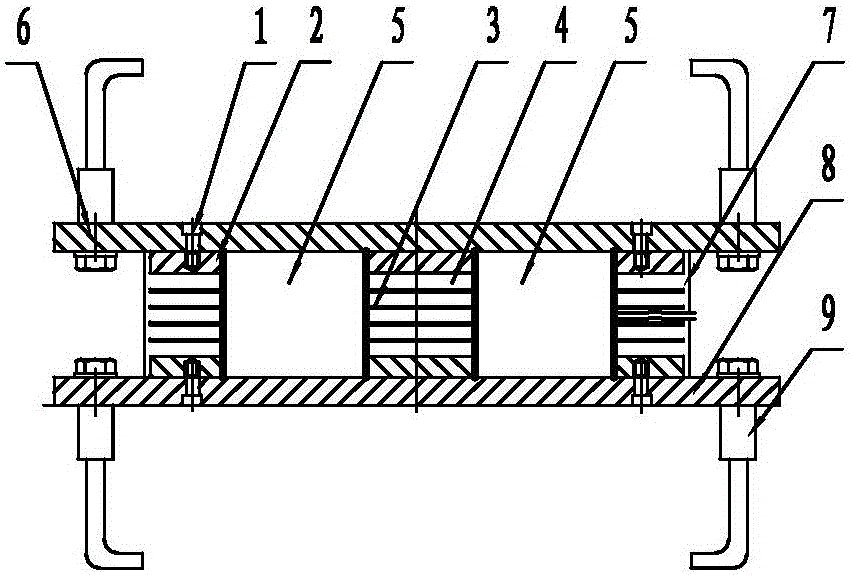

[0050] Such as Figure 5 ~ Figure 6 , oneA damping combined type building shock-isolation rubber bearing, comprising an upper outer connecting steel plate 6, a lower outer connecting steel plate 8 and a bearing core, the bearing core includes a sealing plate 2, a stiffening steel plate 3, a high damping rubber layer 4 and The rubber protection layer 7, the sealing plate, the stiffened steel plate, the high damping rubber layer and the rubber protection layer are integrated into a whole through thermal vulcanization molding, and the support core is connected with the upper outer connecting plate 6 and the lower outer through connecting bolts 1 The steel plate 8 is connected, and the center of the support core body is provided with 4 rod holes along the axial direction, and a high damping metal material rod 5 is installed in the rod hole, and the high damping metal material rod is combined with the support core body.

[0051] The outer connecting steel plate is circular, and th...

Embodiment 2

[0058] one A kind of damping combination type building shock-isolation rubber bearing, its basic structure is identical with embodiment 1, and the component weight portion that forms high damping rubber layer is as follows:

[0059] a. 60g of natural rubber, b. 40g of neoprene, c. 0.1g of stearic acid,

[0060] d. Accelerator CBS 0.5g, e. Anti-aging agent RD 3g, f. Zinc oxide 5g,

[0061] g. protective wax 2g, h. N234 carbon black 12g, i. silane 5g, j. sulfur 1g.

Embodiment 3 Embodiment 10

[0063] one The basic structure of this damping combined building shock-isolation rubber bearing is the same as that of Embodiment 1. For the components by weight of the high-damping rubber layer of each embodiment, see Attached Table 1.

[0064] The above-mentioned embodiment 1 to embodiment 10 are preferred implementation solutions of the present invention, but the technical solution of the present invention is not limited to the above-mentioned embodiments, as a transformation of the above-mentioned embodiment 1 to embodiment 10:

[0065] 1. The number of rod holes opened by the core body of the support for installation of high-damping metal rods can be determined according to the actual needs of construction engineering design, or one (see attached Figure 1 ~ Figure 2 ), or for 3 (see attached Figure 3 ~ Figure 4 ), generally 1 to 4;

[0066] 2. The high damping metal material rod can also be made of tin, or Mn-Cu alloy or Mg alloy material;

[0067] 3. above. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com