Ejection refrigerating cycle device

A refrigeration cycle and ejector technology, which is used in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of narrow operating condition range and low mixing efficiency of ejector refrigeration cycle inverter air conditioners, and achieve simple structure and material saving. and the effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

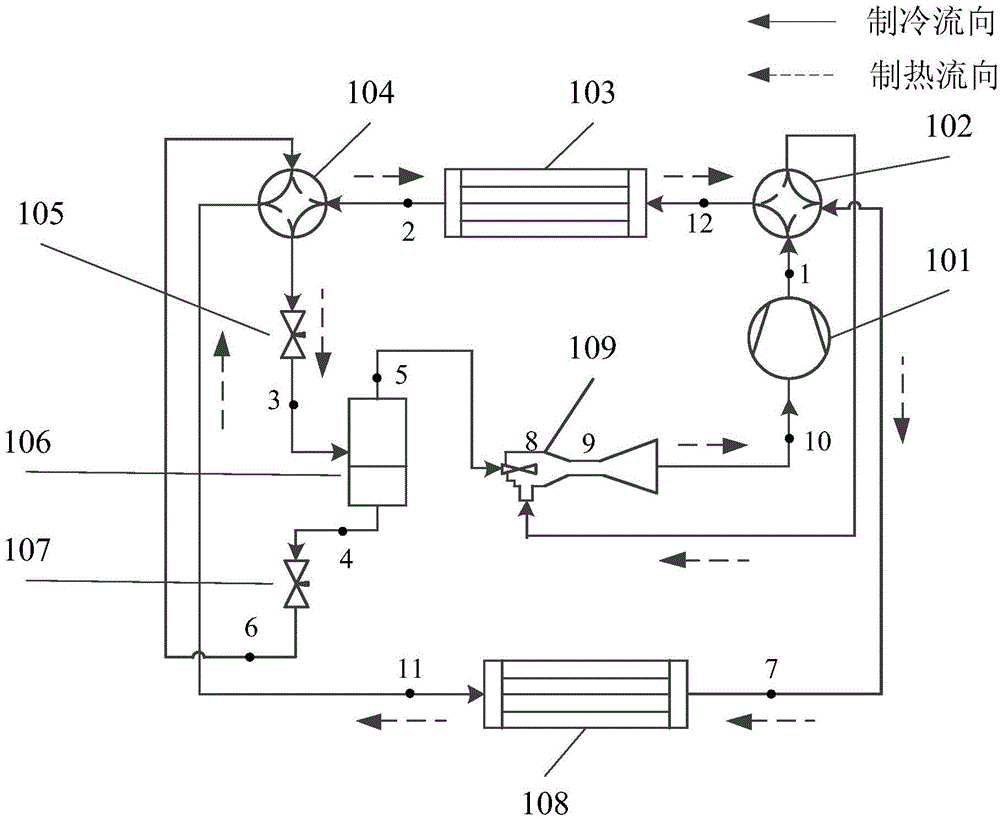

[0041] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, preferably, this embodiment provides an injection refrigeration cycle device suitable for variable working conditions, including a compressor 101, a first four-way reversing valve 102, an outdoor heat exchanger 103, a second four-way Reversing valve 104, first electronic expansion valve 105, gas-liquid separator 106, second electronic expansion valve 107, indoor heat exchanger 108, ejector 109; ejector 109 includes: ejector nozzle 201, ejector Receiver chamber 202, ejector mixing chamber 203, ejector diffuser chamber 204.

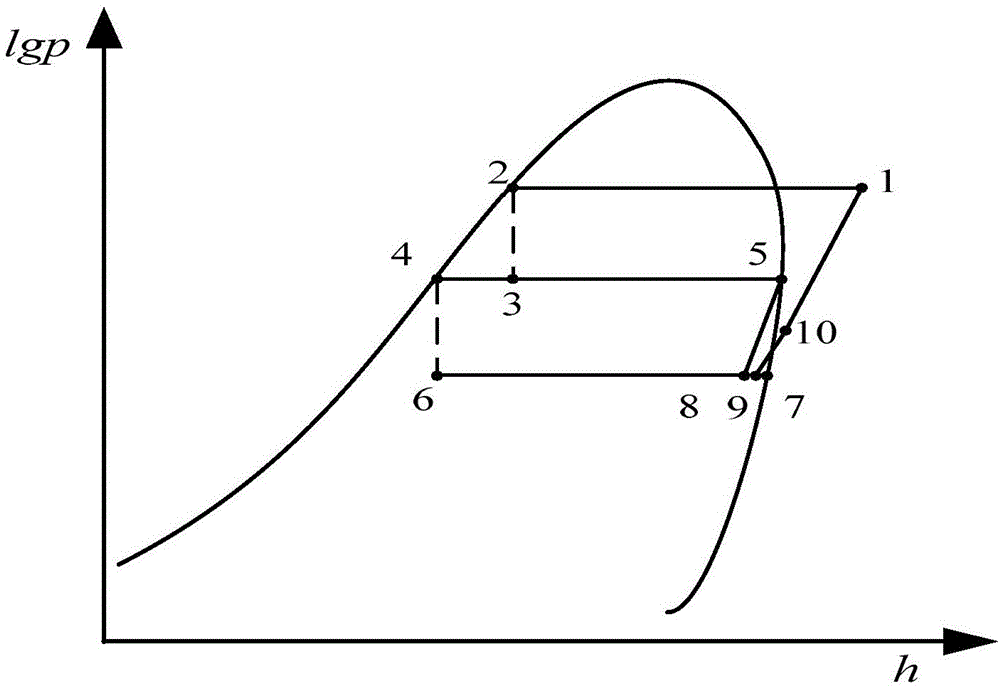

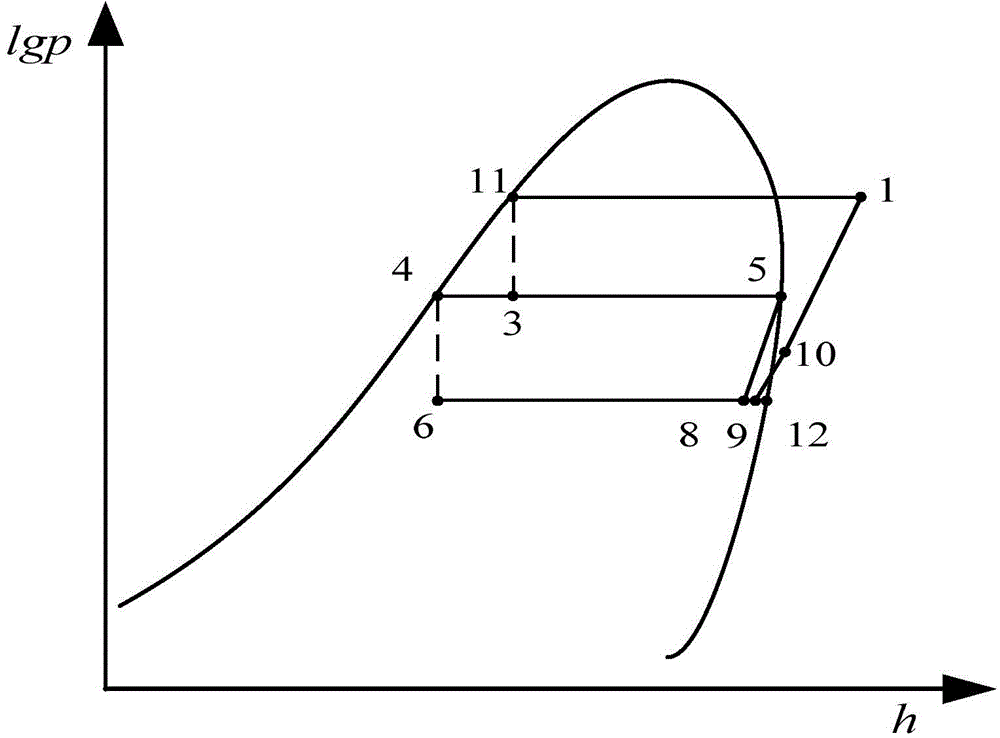

[0042] to combine figure 1 , Figure 4 And refrigeration operation pressure enthalpy lgP-h figure 2 , when the system is in cooling operation, the high-temperature and high-pressure refrigerant is discharged from the compressor 101 (state point 1), passes through the first four-way reversing valve 102 and enters the outdoor heat exchanger 103 to condense and becomes a low-temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com