Pneumatic material impact test device simulating shooting of bullet (cannonball)

An impact test, pneumatic technology, applied in the direction of using one impact force to test the strength of materials, can solve problems such as difficult to carry out, and achieve the effect of accurate test, accurate impact energy test and large range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

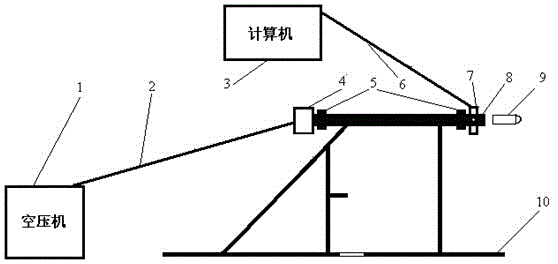

[0020] The pneumatic material impact test device imitating the shooting of bullets (guns) is mainly composed of air compressor (1), computer (3), solenoid valve (4) equipped with jog switch, magnet (5), photoelectric speedometer (7) , launch tube (8), shock bullet (9), support (10) etc. to form. The air compressor (1) is connected with the solenoid valve (4) and the launch tube (8) through the plastic hose (2) to form the compressed air circuit of the impact test device. Drill two small holes with a diameter of about 2mm symmetrically in the center where the photoelectric velocimeter (7) is installed in the launch tube (8) to ensure that the light of the photoelectric velocimeter (7) can pass through the launch tube (8). In order to ensure accurate measurement of the velocity and energy of the impact bomb (9), the minimum distance from the center of the small hole to the mouth of the launch tube (8) is half the thickness of the photoelectric speedometer (7), and the maximum di...

Embodiment 2

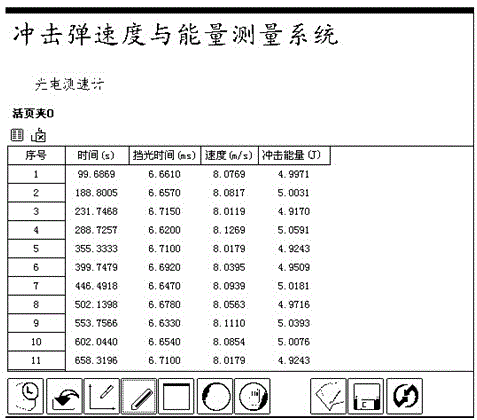

[0023] figure 2 For the impact test of materials, the impact bomb energy calculation and statistical table displayed by the computer. After the impact bullet passes through the photoelectric speedometer, the computer can measure the light blocking time of the impact bullet in real time and calculate the speed of the impact bullet according to the length of the impact bullet. At the same time, the impact energy of the impact bomb is automatically calculated according to the mass of the impact bomb and displayed on the computer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com