Deep ploughing scarifier

A technology of soil loosening machine and frame, which is applied in the direction of tillage machines, collectors, agricultural machinery and tools, etc. It can solve the problems of reduced soil crushing capacity, increased soil resistance, and residues, so as to ensure soil crushing, reduce labor force, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

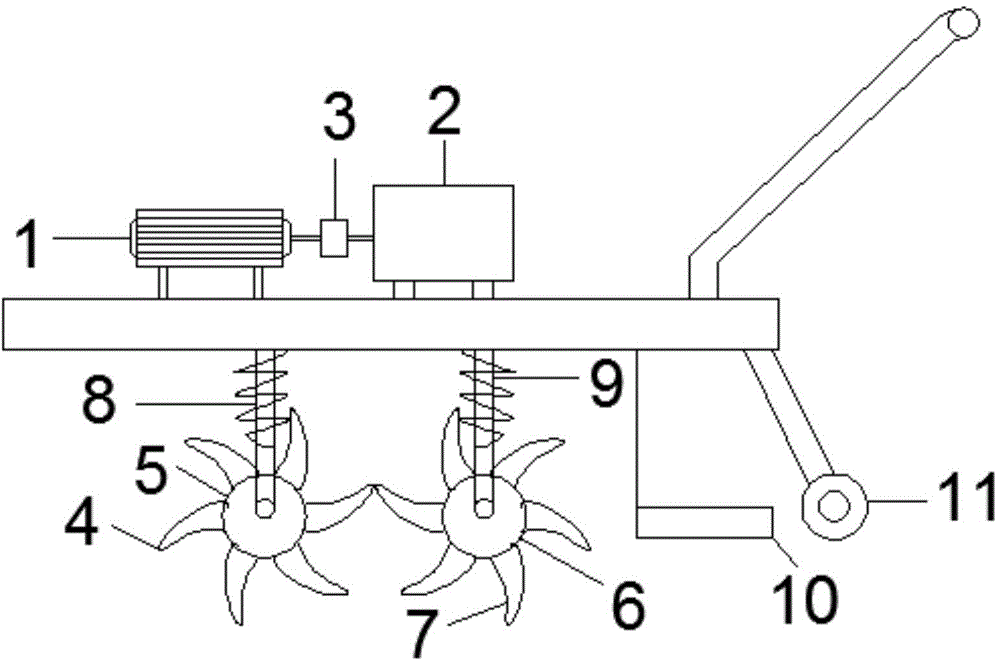

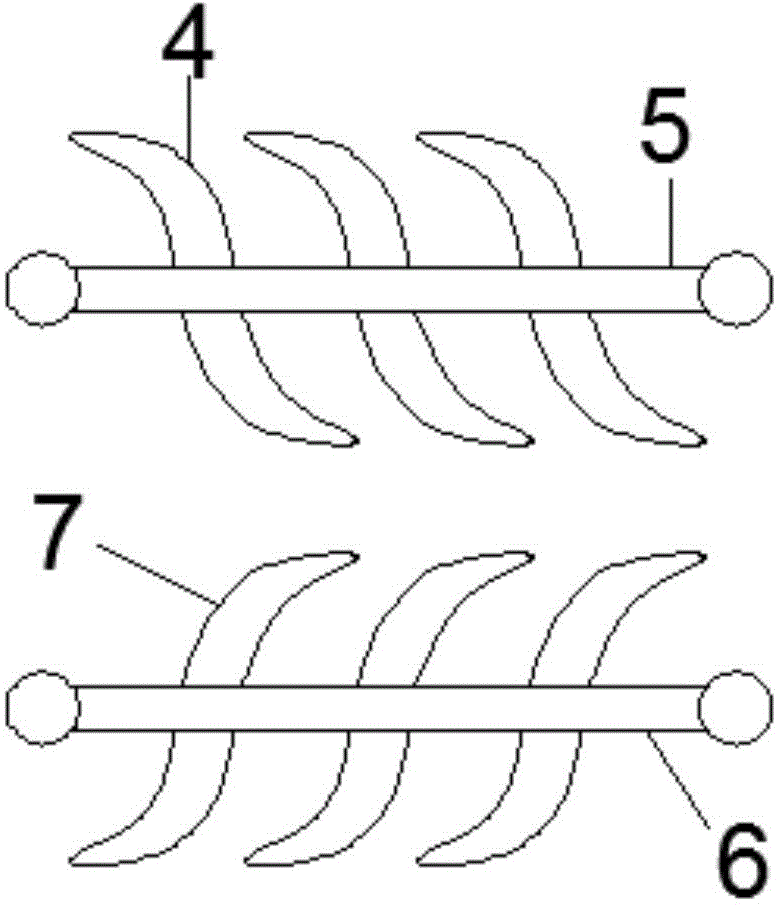

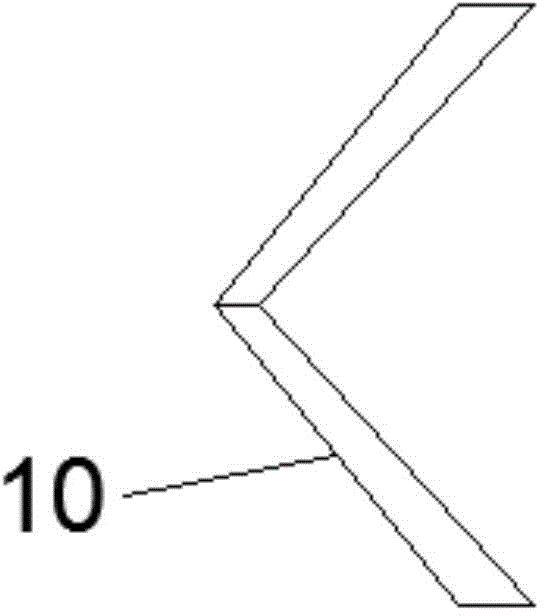

[0022] Such as figure 1 with figure 2 As shown, a deep plowing ripper includes a frame, a reducer 1 and a motor 3, the reducer 1 and the motor 3 are connected by a coupling 2, and a roller 11 is installed at the bottom right of the frame, so The first roller 5 and the second roller 6 are installed below the frame, the first roller 5 is connected with the frame through the first connecting shaft 8, and the second roller 6 is connected with the frame through the second connecting shaft 9. The frame is connected, and the first roller 5 and the second roller 6 are respectively equipped with a plurality of first blades 4 and a plurality of second blades 7, and the first blades 4 and the second blades 7 are alternately arranged.

[0023] When the deep plowing ripper performs deep plowing and loosening operations, the motor 3 drives the rollers to move forward, and the blades on the first roller 5 and the second roller 6 excavate and pulverize the soil. Because the first blade 4 an...

Embodiment 2

[0029] The rest are the same as in Embodiment 1, and the first connecting shaft 8 and the second connecting shaft 9 are respectively equipped with air cylinders. With this structure, the distance between the first connecting shaft 8, the second connecting shaft 9 and the first roller 5 and the second roller 6 can be automatically adjusted according to the softness of the soil. Soil; when the soil was relatively hard, the cylinder was compressed, and the pressure exerted on the first roller 5 and the second roller 6 increased, which could ensure that the soil depth of the deep plowing loose soil operation was basically the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com