Motor vehicle multi-voltage vehicle circuit, its operation method and mechanism for realizing the method

A multi-voltage, motor vehicle technology, applied in the direction of motor starting for engines, machines/engines, battery circuit devices, etc., can solve problems such as vehicle failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

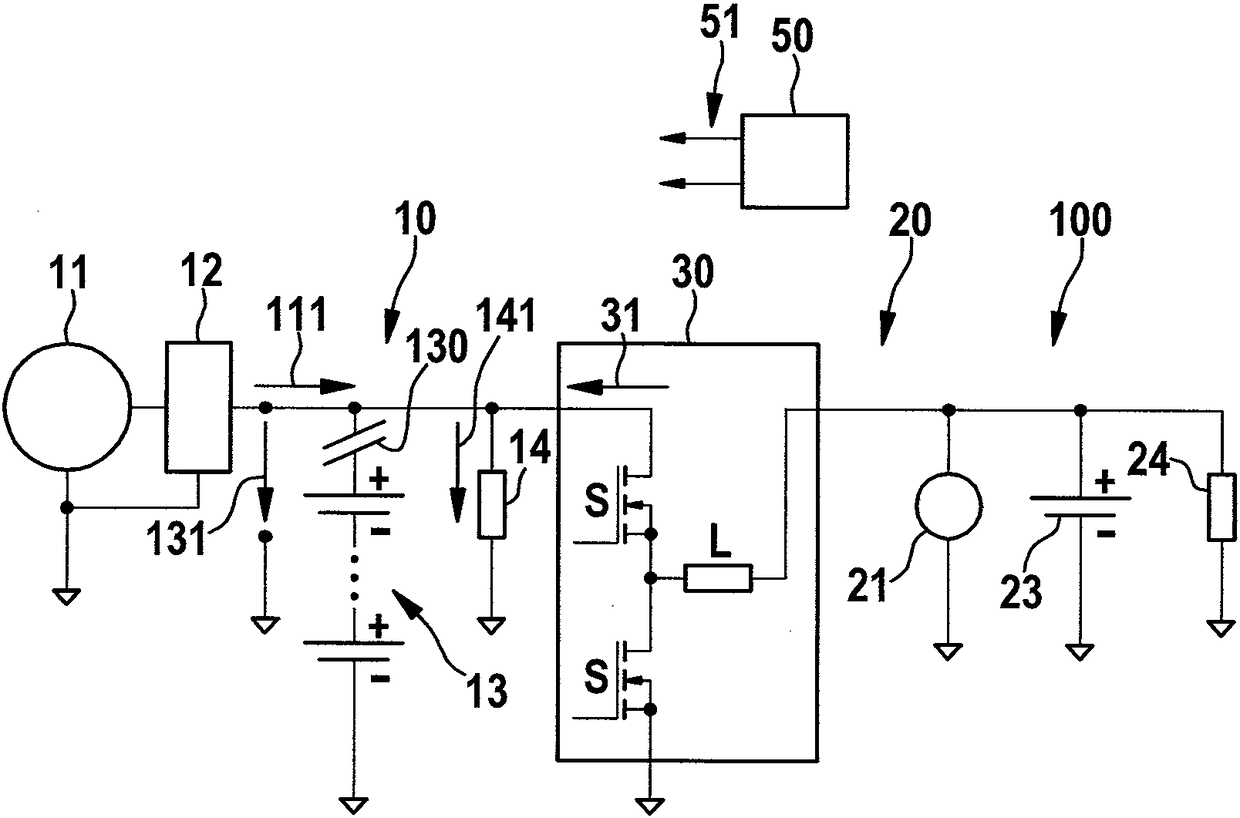

[0033] In the figures, elements corresponding to each other are identified with the same reference numerals and will not be explained repeatedly.

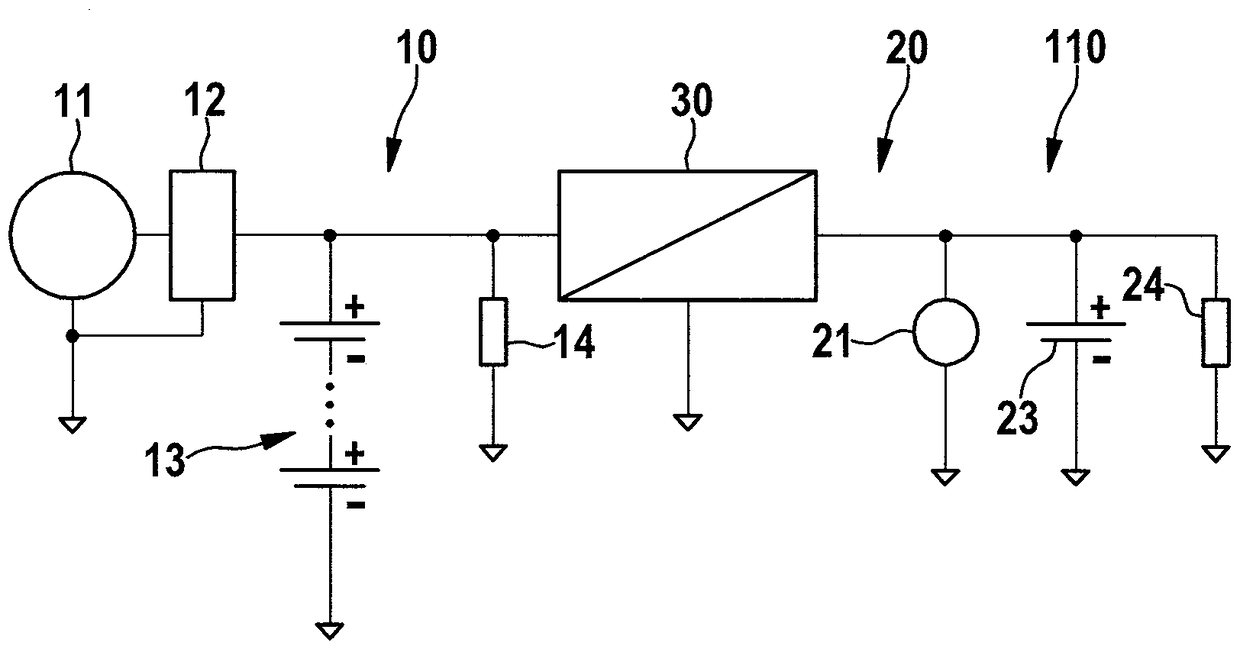

[0034] figure 1 A dual-voltage vehicle circuit not according to the invention is shown in the form of a schematic wiring diagram. The dual-voltage automotive circuits are denoted by 110 in their entirety.

[0035] The dual-voltage automotive circuit 110 has a first sub-circuit 10 and a second sub-circuit 20 . The first subcircuit 10 is here designed, for example, for operation with 48V as operating voltage. The second subcircuit 20 is designed here, for example, for operation with 12V as operating voltage. The first subcircuit 10 is thus a so-called high-voltage subcircuit, while the second subcircuit 20 is a so-called low-voltage subcircuit.

[0036] An electric machine 11 with a converter 12 is arranged in the first partial circuit 10 . The electric machine 11 can be operated at least as a generator and can feed current into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com