Fly ash cement and preparation method thereof

A technology for fly ash cement and fly ash, which is applied in the field of fly ash cement and its preparation, can solve the problems of occupying large farmland, destroying ecological balance, groundwater and air pollution, etc., so as to reduce pollution, improve quality, and reduce The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

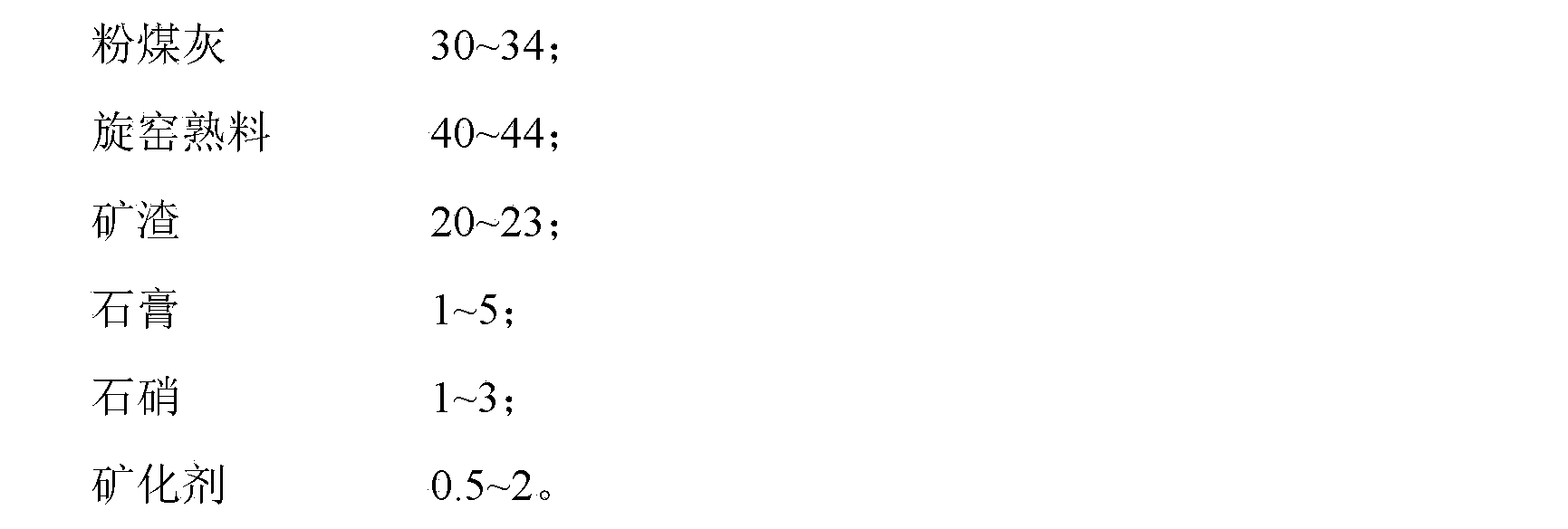

[0034] A kind of fly ash cement, its composition and parts by weight are as follows:

[0035]

[0036] The preparation method of fly ash cement as mentioned above, step is as follows:

[0037] After weighing the fly ash, rotary kiln clinker, slag, gypsum, and stone salt, after drying, they are respectively sent to the mill for fine grinding, and the powdered materials obtained after fine grinding are homogenized, and the homogenized The final raw materials are mixed and ground after mixing. Mineralizer is added during grinding, and the grinding time is more than 25 minutes to obtain fly ash cement.

Embodiment 2

[0039] A kind of fly ash cement, its composition and parts by weight are as follows:

[0040]

[0041] The preparation method of fly ash cement as mentioned above is the same as embodiment 1.

Embodiment 3

[0043] A kind of fly ash cement, its composition and parts by weight are as follows:

[0044]

[0045]

[0046] The preparation method of fly ash cement as mentioned above is the same as embodiment 1.

[0047] Fly ash cement detection result of the present invention:

[0048] The fly ash cement of the invention is tested and exceeds the national P?F32.5 fly ash cement standard, and its strength level is not inferior to that of traditional slag P?S?A32.5 cement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com